Hydraulic sorting system

A sorting system and hydraulic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency and achieve the effect of easy operation, high product quality and good work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

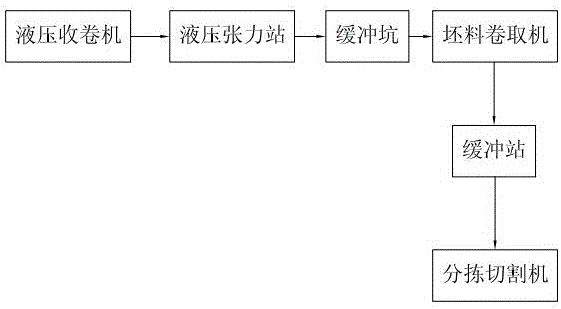

[0010] Such as figure 1 As shown, the hydraulic sorting system of this embodiment includes a hydraulic winder, and the output end of the hydraulic winder is provided with a hydraulic tension station, and the material after tension in the hydraulic tension station enters the buffer pit, and then passes through the billet coiler Carry out coiling, and then enter the buffer station after coiling, and enter the sorting and cutting machine after buffering for sorting.

[0011] In the actual use process, the hydraulic winder first transports the raw materials, and after the tension test of the raw materials, it enters the buffer pit for buffering, and the billet after coiling is buffered through the buffer station to give the billet a good buffer time, and finally Then sort and cut. Work reliability is good, product quality is excellent.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com