Dull polishing tool

A sanding and tooling technology, which is applied in the direction of grinding/polishing hand tools, manufacturing tools, metal processing equipment, etc., can solve the problems of time-consuming, low work efficiency, and affecting the sanding effect, and achieve high efficiency, convenient replacement, and good grinding effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

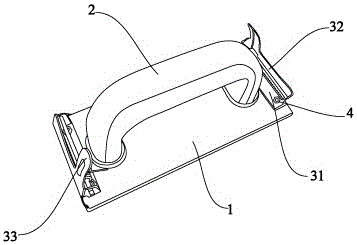

[0011] As shown in Figure 1, the sanding tool of the present invention includes a base 1 and a handle 2 fixed on the base 1, and a clamping device 3 is pivotally provided at both ends of the base, and the clamping device 3 is used to The replacement frosting material is clamped on the bottom surface of the base 1 movably for grinding the surface of the workpiece. The handle 2 is located between the two clamping devices 3, wherein the handle 2 is a crank, which is not only beautiful, but also easy to hold and use force.

[0012] The clamping device 3 includes a base 31 fixedly connected with the base 1 and a clamping part 32 movably connected with the base 31, the base 31 is fixedly connected with the base 1 through a nut 4, and one end of the clamping part 32 Extending toward one side of the handle 2 is a projection 33 that facilitates applying force to the clamping devic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap