An adjustable position loading device

A technology for carrying objects and stages, which is applied in the direction of workbenches and manufacturing tools, which can solve the problems of poor stability, difficulty in synchronous lifting and lowering of screw rods, inconvenience, etc., and achieve improved motion stability, low device cost, and easy height adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

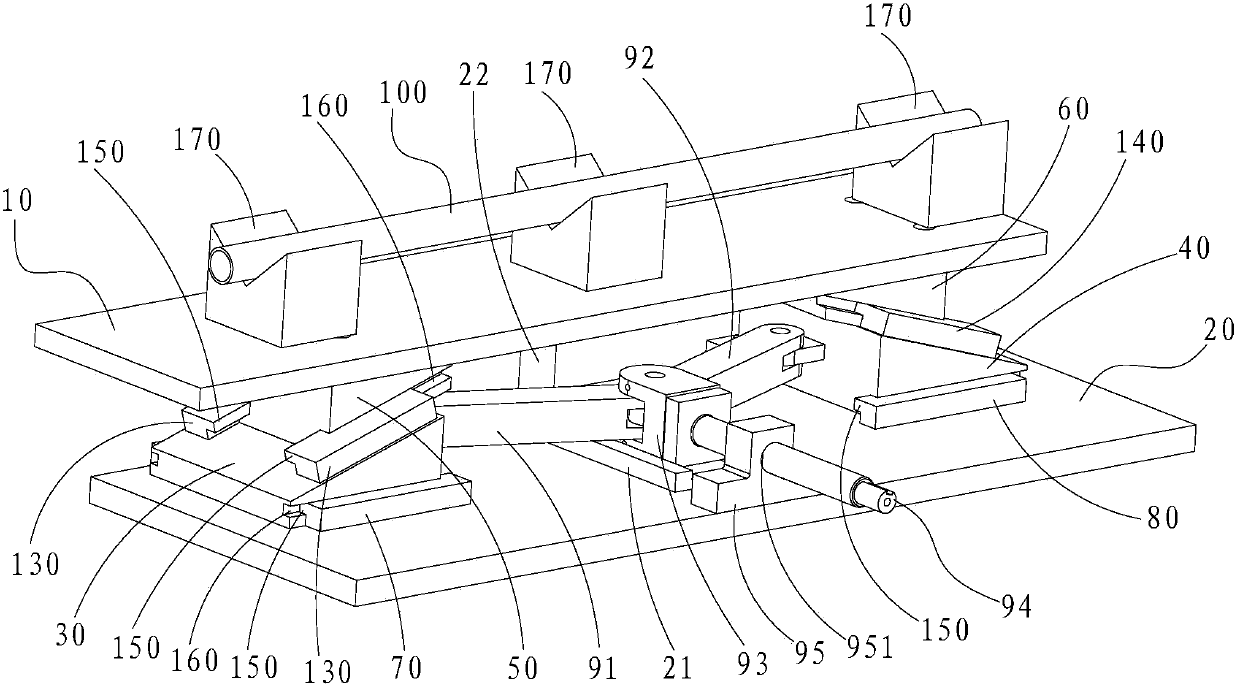

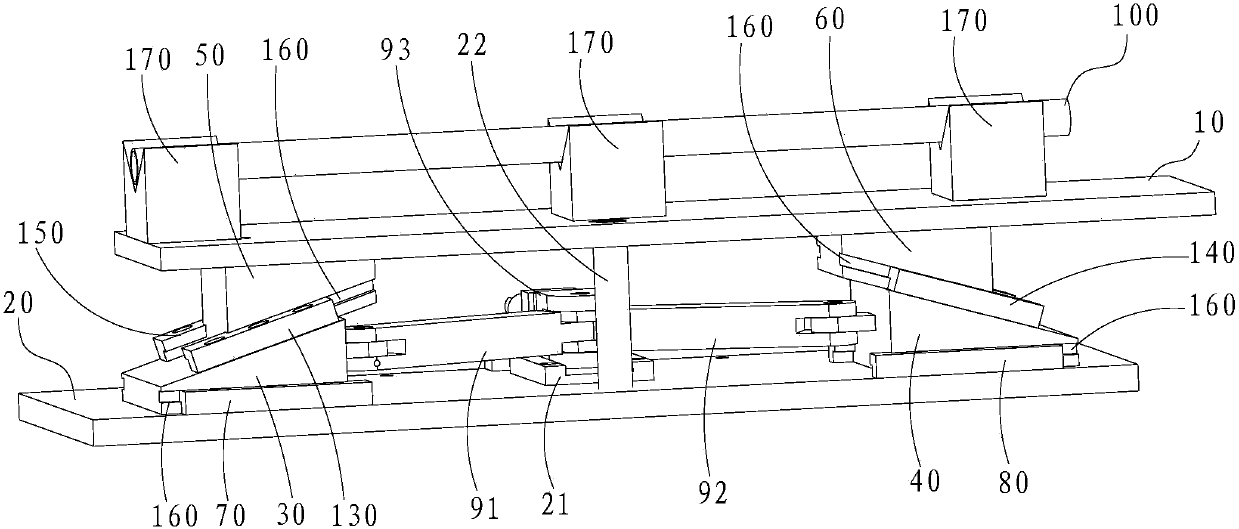

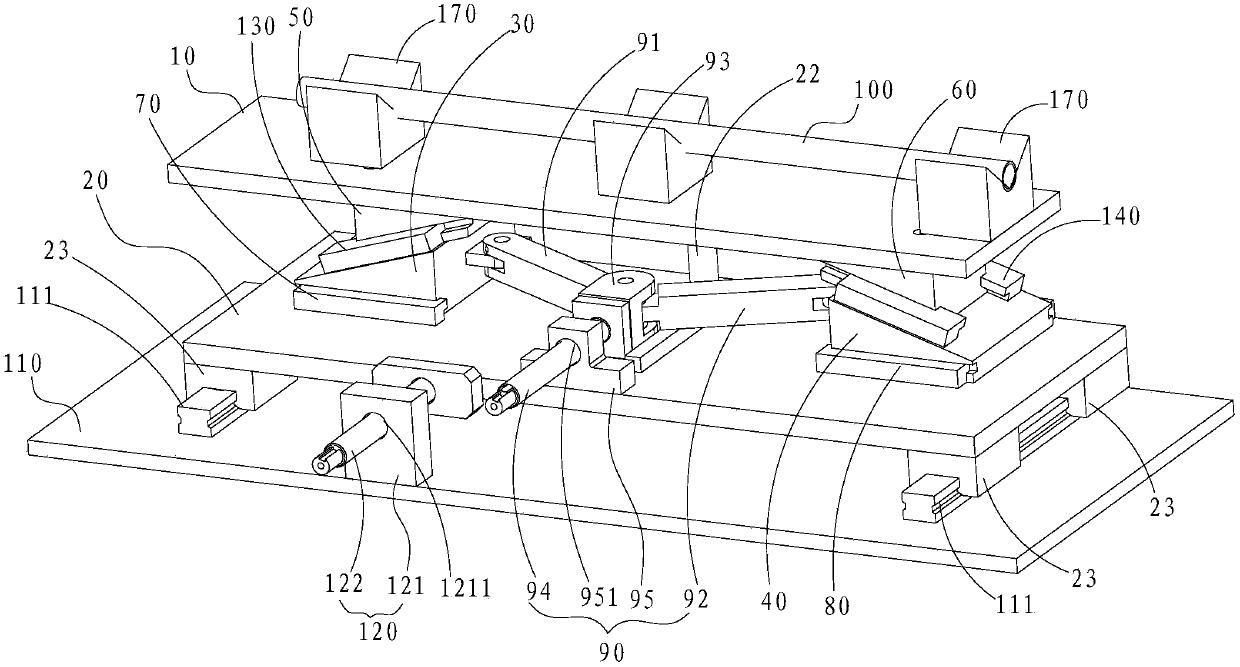

[0032] like Figure 1-3 As shown, the adjustable position loading device of the present invention includes a workpiece stage 10, a base plate 20, a first wedge 30, a second wedge 40, a third wedge 50, a fourth wedge 60, The first guide block 70 , the second guide block 80 and the first driving mechanism 90 .

[0033] The workpiece stage 10 is used for placing a workpiece 100 . The substrate 20 is set opposite to the work stage. The first wedge 30 is disposed opposite to the second wedge 40 and is slidably disposed on the base plate 20 . The third wedge 50 and the fourth wedge 60 are connected to the working stage. The slope of the first wedge 30 is in contact with the slope of the third wedge 50 , and the first wedge 30 and the third wedge 50 can slide against each other. The slope of the second wedge 40 is in contact with the slope of the fourth wedge 60 , and the second wedge 40 and the fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com