Surface treatment process of fiber composite material with laser effect

A fiber composite material and processing technology, applied in metal material coating process, household appliances, sputtering coating, etc., can solve the problems of complex coating process, easy falling off of information layer, monotonous color, etc., to reduce environmental pollution , good curing effect, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

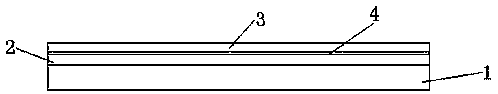

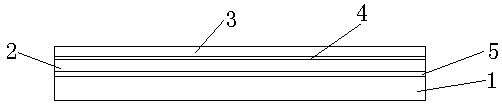

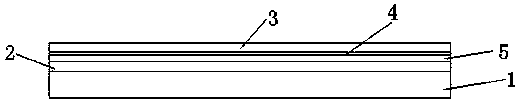

[0046] Surface structure of fiber composites with laser effect (cf. figure 1 ), cured and formed on the outer surface of the fiber composite product 1, including a laser information layer 2 and an information protection layer 3 that are sequentially coated on the outer surface of the fiber composite product 1 from inside to outside; wherein, the information protection Layer 3 is molded with patterns or text information, so an information texture surface layer 4 is formed between the laser information layer 2 and the information protection layer 3, and the laser information layer 2 is coated on the information texture surface layer 4; the laser information layer 2 is a metal layer; the information protection layer 3 is a resin layer; the laser information layer 2 can be made into a structure with effects such as full-page, hollowed out, and matte according to needs; further, in order to increase the color effect, it can also be A color layer 5 is added; the color layer 5 is coa...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is that

[0049] The color layer 5 is coated between the laser information layer 2 and the information texture surface layer 4 of the information protection layer 3 .

Embodiment 3

[0051] The difference between this embodiment and embodiment 1 is that

[0052] The color layer 5 is coated on the upper surface of the information protection layer 3; a layer of varnish protection layer 6 is coated on the color layer 5 to protect the color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com