Automatic drying equipment for non-metallic mineral forming filter cakes

A technology of non-metallic ore forming and drying equipment, which is applied in the direction of static material dryers, dry solid materials, and dry cargo handling, etc., and can solve the problems of long drying cycle, large floor space, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Embodiment: A kind of automatic drying equipment of non-metallic ore shaped filter cake

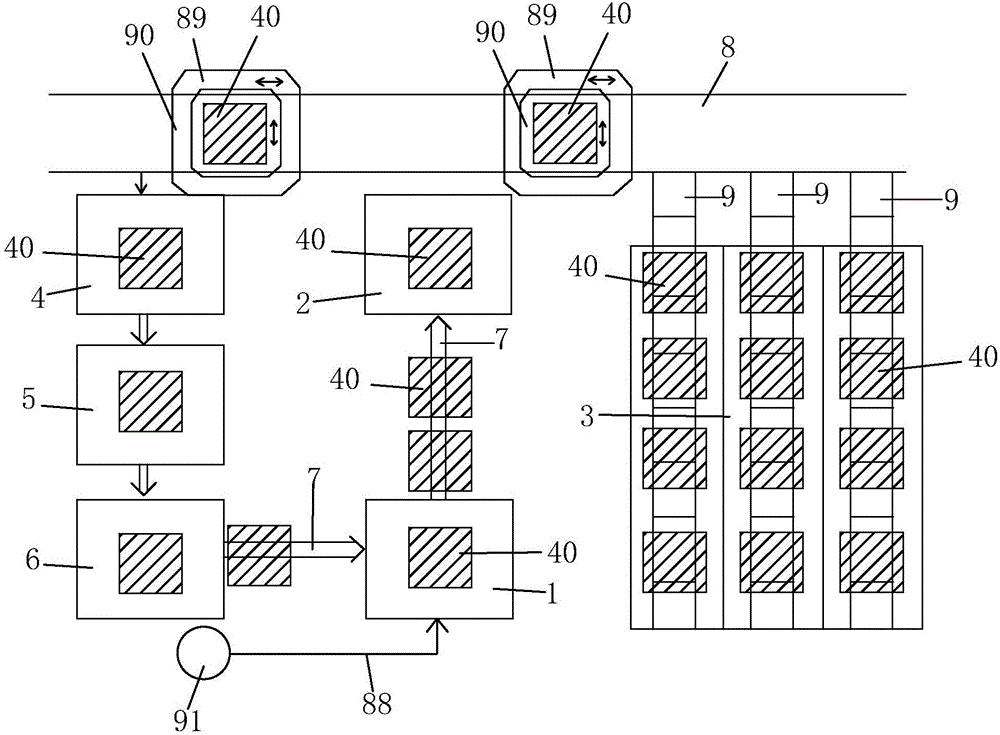

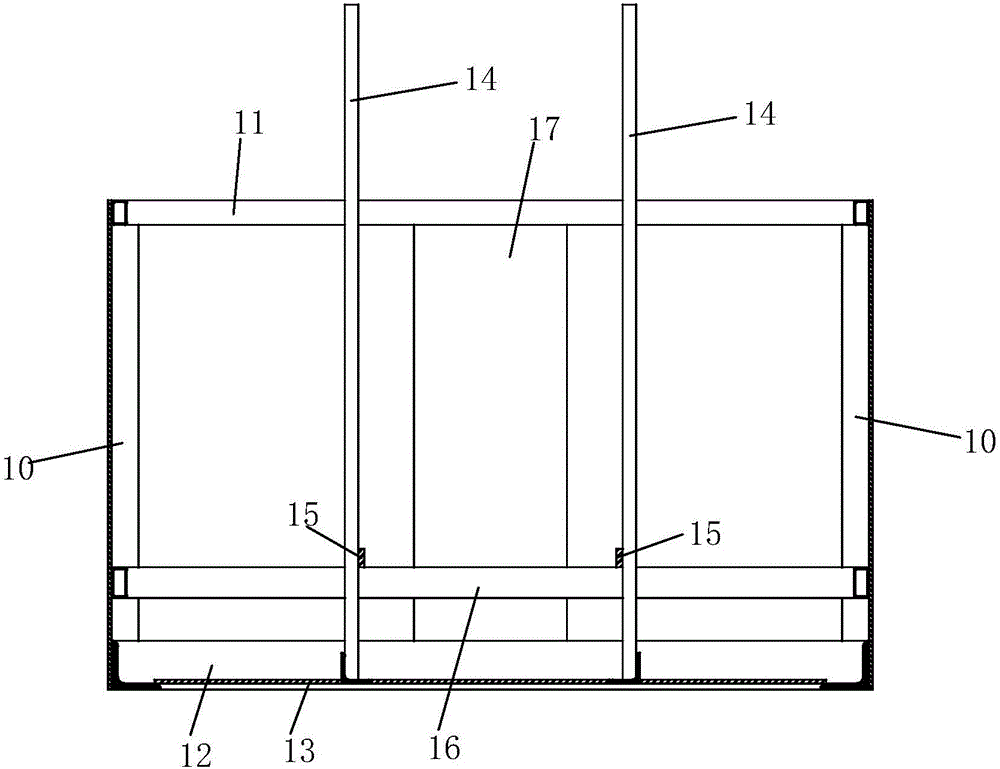

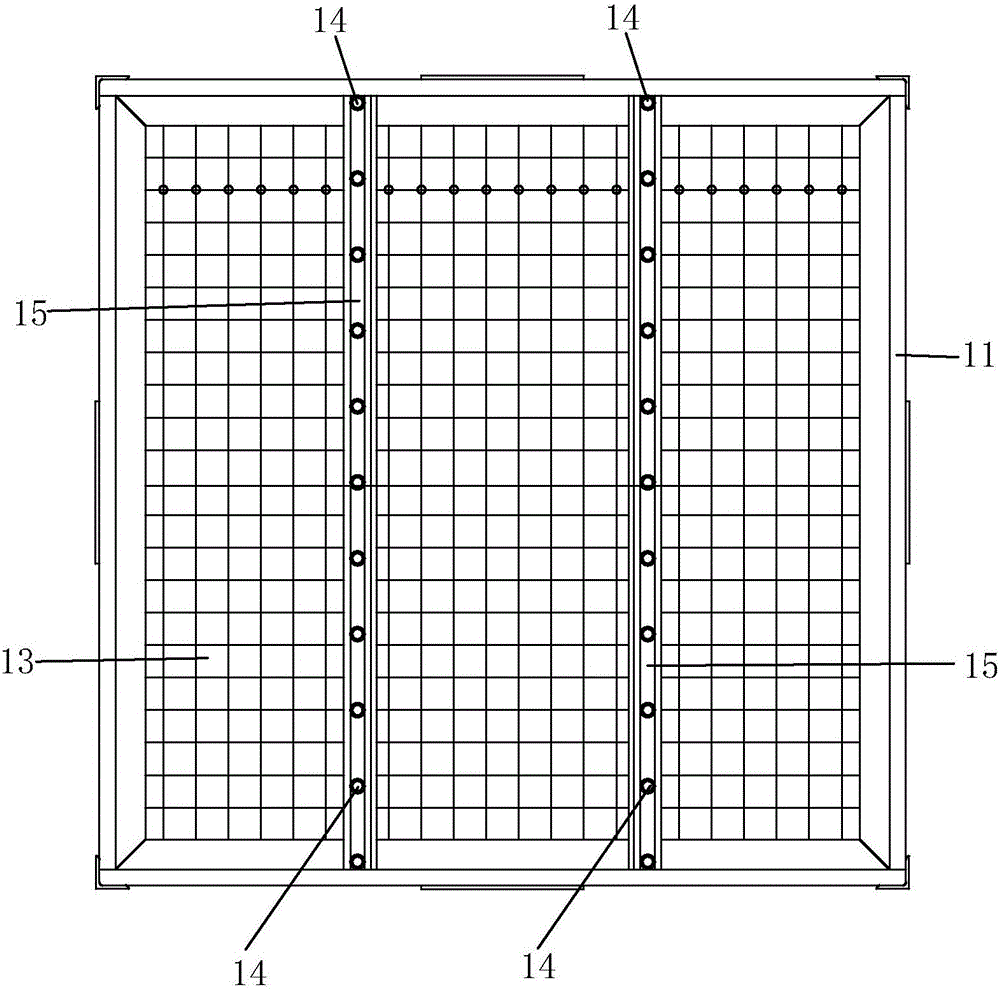

[0060] See attached figure 1 to attach Figure 22 As shown, the automatic drying equipment includes a drying frame 40 capable of loading non-metallic ore shaped filter cakes and a closed-loop transport track, and the drying frame 40 circulates on the closed-loop transport track, and the transport track consists of the drying frame track 7, The mother car track 8 and the sub-car track 9 are composed. According to the running track of the drying frame 40 on the transport track, the drying frame 40 passes through the feeding station 1, the first lifting frame station 2, the drying station 3, and the second lifting frame in sequence. Station 4, unloading station 5 and lowering frame station 6, the running direction of drying frame 40 is irreversible, described feeding station 1 is connected with the first lifting frame station 2 through described drying frame track 7, described fallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com