Vacuum feeding device

A technology of vacuum feeding and powder bucket, which is applied in transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of unsatisfactory elevator, laborious feeding, time-consuming and laborious feeding operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

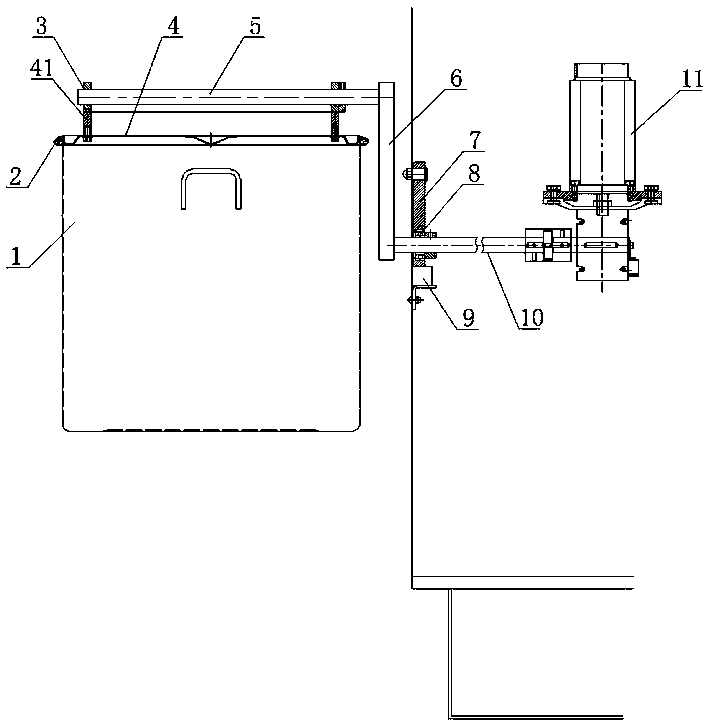

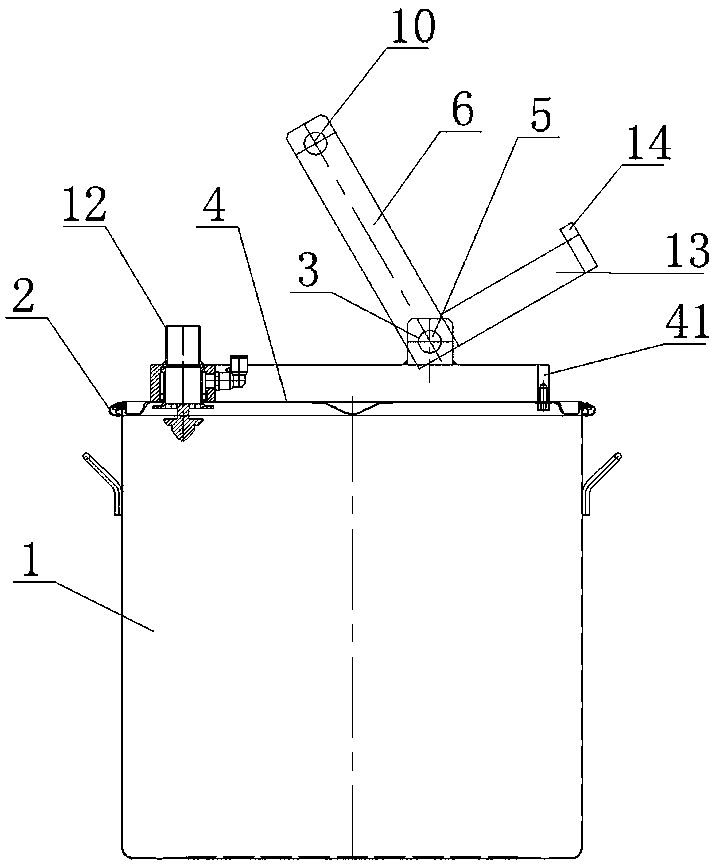

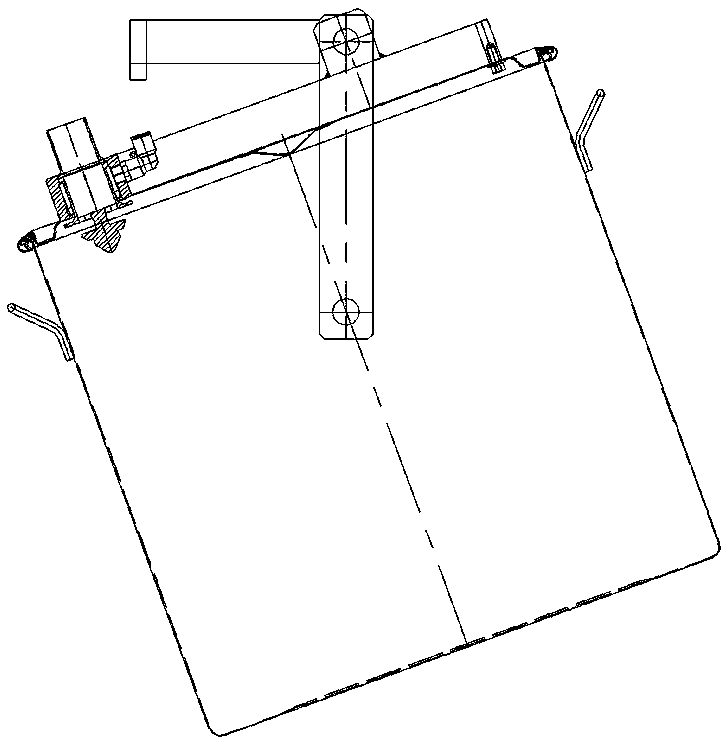

[0015] As shown in the figure, the vacuum feeding device of the present invention includes a raw powder barrel 1, the barrel mouth of the raw powder barrel 1 is connected to the barrel cover 4 through a clamp 2, and the barrel cover 4 is equipped with a delivery pipe 12 with an arch-removing design to transport The tube 12 is located on the left side of the bung 4, and the center of the bung 4 is provided with a lifting lug hole 3 to the right, and a rotating shaft 5 is arranged in the lifting lug hole 3, and the rotating shaft 5 is fixedly connected to the swing rod 6, and the swing rod 6 is vertically The plane swings in a circle, the swing rod 6 is connected with the transmission shaft 10, and the transmission shaft 10 is driven by the servo motor 11. When the transmission shaft 10 rotates, the swing rod 6 and the rotating shaft 5 drive the raw powder bucket 1 to lift, and the rotating shaft 5 is fixed on the auxiliary The rod 13, the auxiliary rod 13 and the swing rod 6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com