High-speed tyre unstacker and unstacking method thereof

A technology for destacking machines and tires, applied in the direction of destacking objects, conveyors, conveyor objects, etc., can solve the problems of high maintenance cost, increased investment cost, low efficiency, etc., and achieves simple and reliable structure, easy maintenance, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

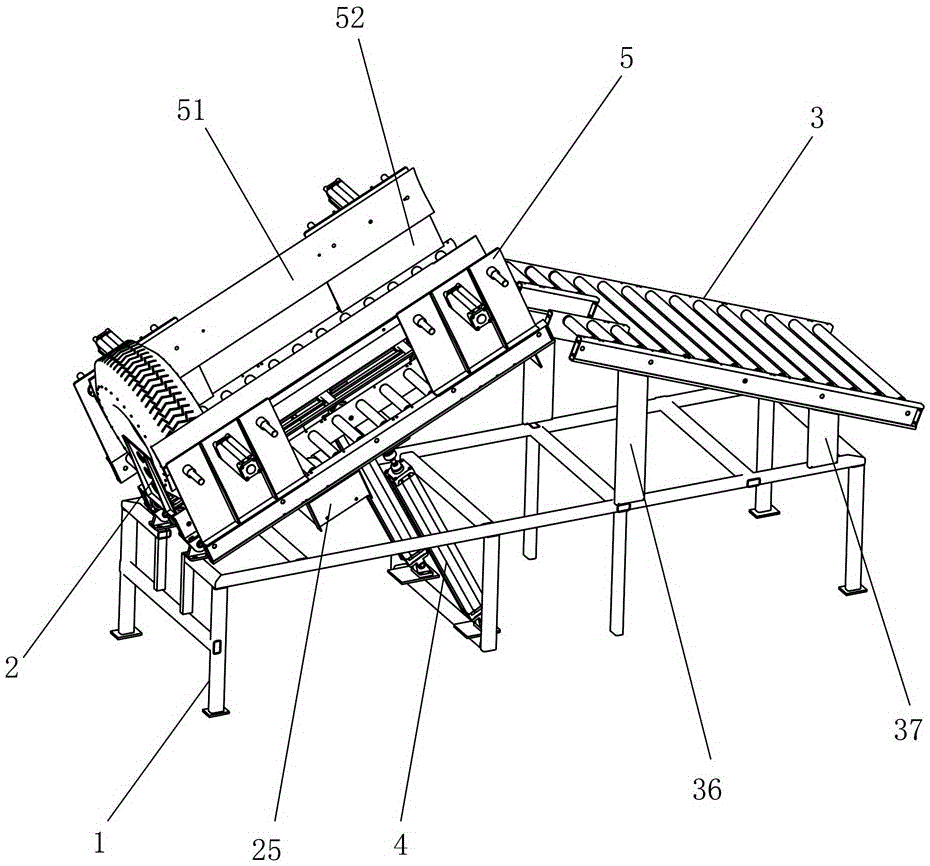

[0034] Such as figure 1 As shown, the high-speed tire destacker of this embodiment includes a frame 1, a lifting mechanism 2, a blanking slideway 3 and a turning mechanism 4 for driving the lifting mechanism 2 to rotate in a vertical plane, and the blanking slideway 3 Tilt clamping mechanism 5 is installed on the lifting mechanism 2, the lower end of the lifting mechanism 2 is hinged with the frame 1, the upper end of the lifting mechanism 2 is docked with the upper end of the blanking slideway 3, and the turning mechanism 4 is installed on the frame 1 and drive connection with the lifting mechanism 2. The high-speed tire stacker makes the stack of tires lift up under the action of the lifting mechanism 2, and the tire on the top of the stack passes through the docking point and then enters the blanking slideway 3 and falls rapidly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com