Integral production line for ultra-low expansion glass-ceramics

A glass-ceramic, integrated technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of difficult control of product quality stability and low production efficiency, achieve stable and controllable product quality, and improve production Efficiency, the effect of realizing production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

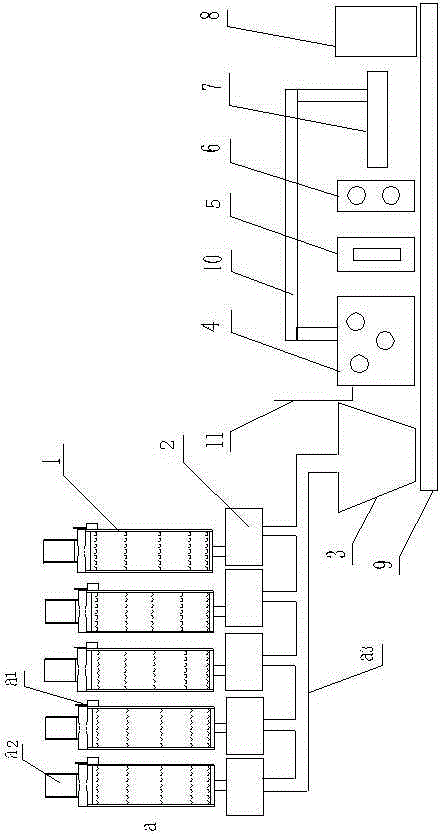

[0011] Such as figure 1 As shown, the ultra-low expansion glass-ceramic integrated production line includes a raw material selection system a, and the raw material selection system a includes several raw material conveyors a1; the raw material conveyor a1 is composed of a raw material conveyor belt a2, an electric screen 1 1. Composition of ingredient weighing device 2, raw material conveyor belt a1 is connected to electric sieve 1, and electric sieve 1 is connected to ingredient weighing device 2.

[0012] Each raw material enters the mixing conveyor belt a2 after the batching and weighing device 2, and the mixing conveyor belt a2 is connected with the mixer 3, and after being mixed by the mixer 3, the fully mixed and uniform raw materials enter the conveying track device 9; On one side of the conveying track device 9 , a melting furnace 4 , a molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com