Double face needle loom

A needle and frame technology, applied in the field of double-face needle looms, can solve the problems of toothed belt skipping teeth, troublesome maintenance, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

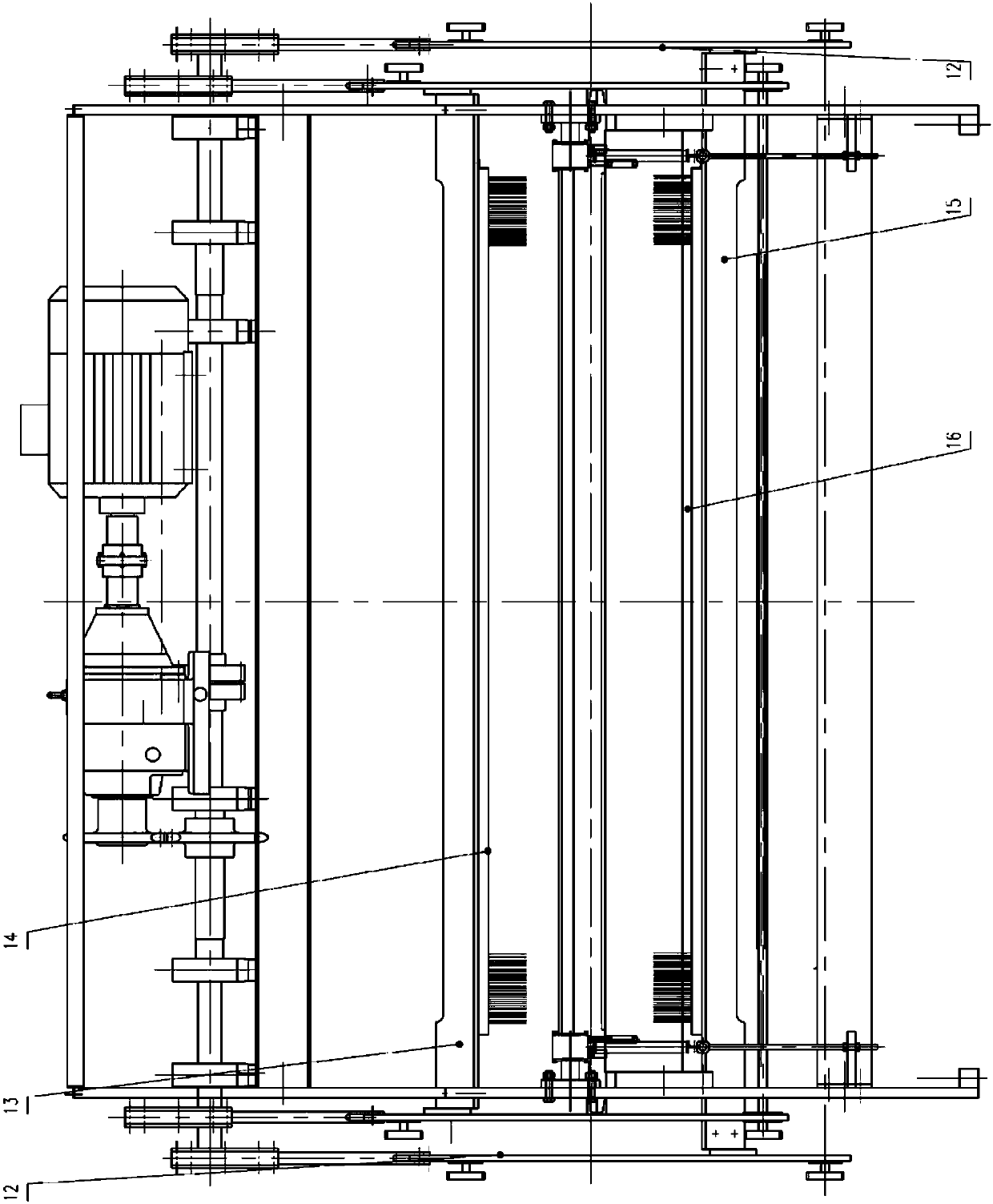

[0019] An embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

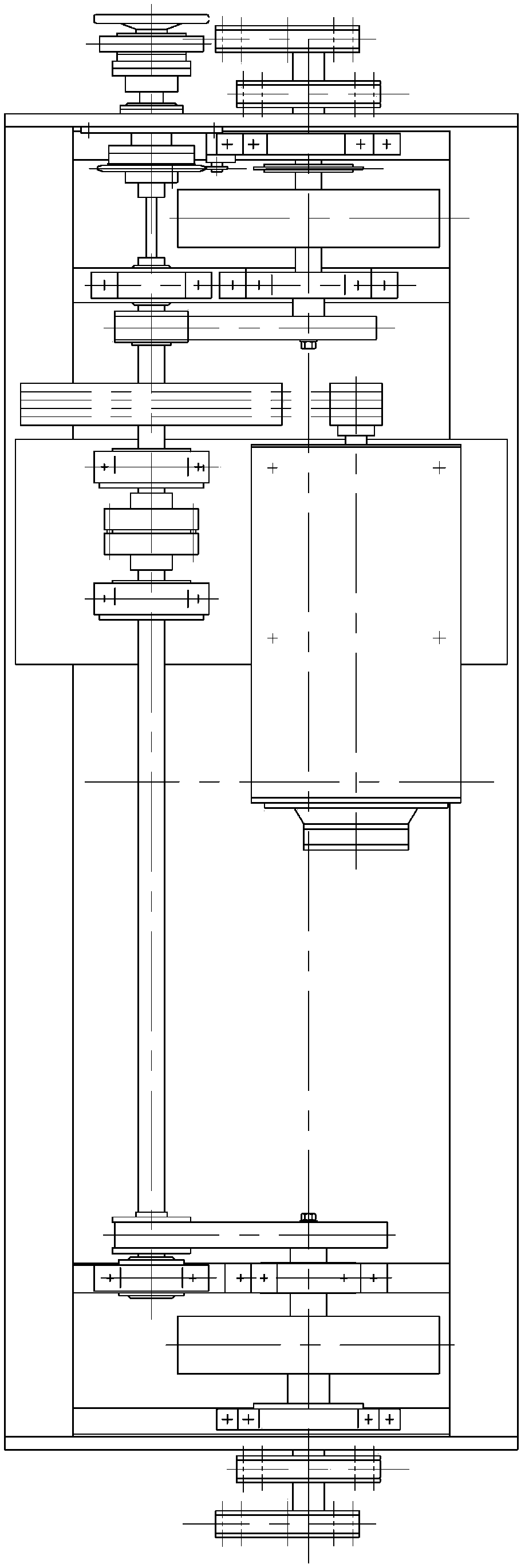

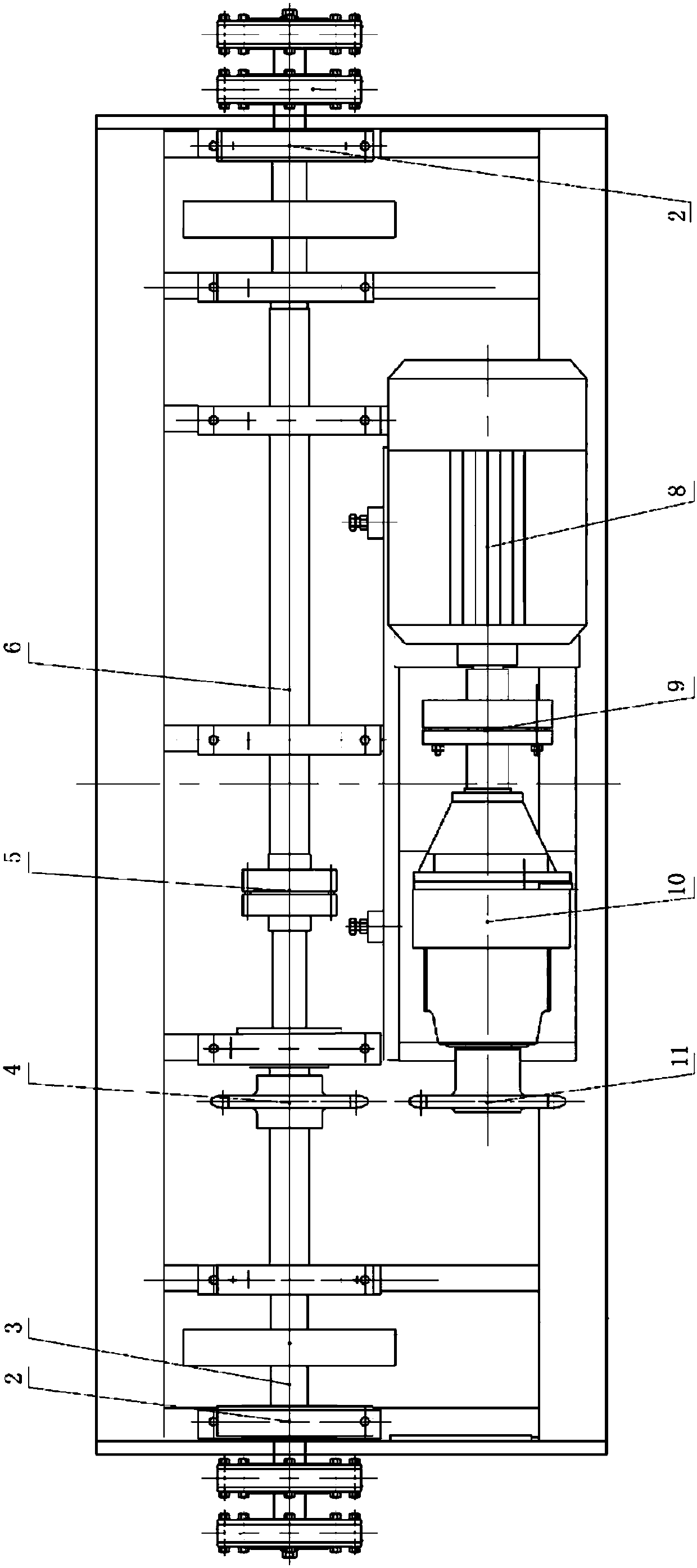

[0020] Such as Figure 1 to Figure 4 As shown, a double-faced needling loom with a pressing plate of the present invention is mainly composed of a main drive system, a double-faced needling system, a swing compacting device, a frame, and the like.

[0021] The main drive system of the present invention consists of motor 8, first coupling 9, reducer 10, first sprocket 11, bearing housing 2, first main shaft 3, second sprocket 4, second main shaft 6, second coupling Shaft device 5 and other components (such as figure 2 shown). When working, it is powered by the motor 8, connected with the reducer 10 through the first coupling 9, the first sprocket 11 is installed on the output shaft of the reducer, the second sprocket 4 is installed on the first main shaft 3, and the first The main shaft 3 is connected with the second main shaft 6 by a second couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com