Multistage folding type spiral conveying mechanism for paver

A technology of screw conveying and paver, which is applied to roads, road repairs, roads, etc., can solve problems such as inability to adapt, achieve the effects of eliminating gaps, novel and reasonable design, and improving paving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

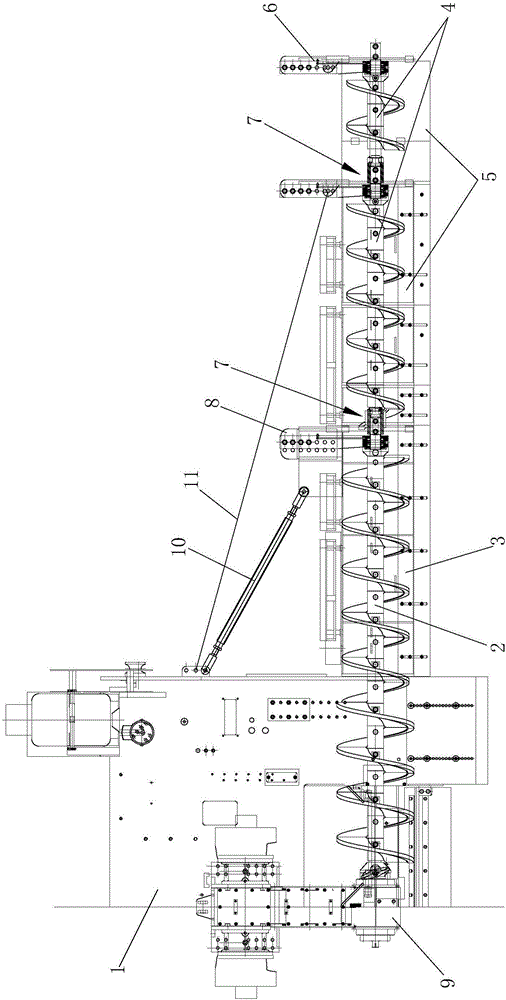

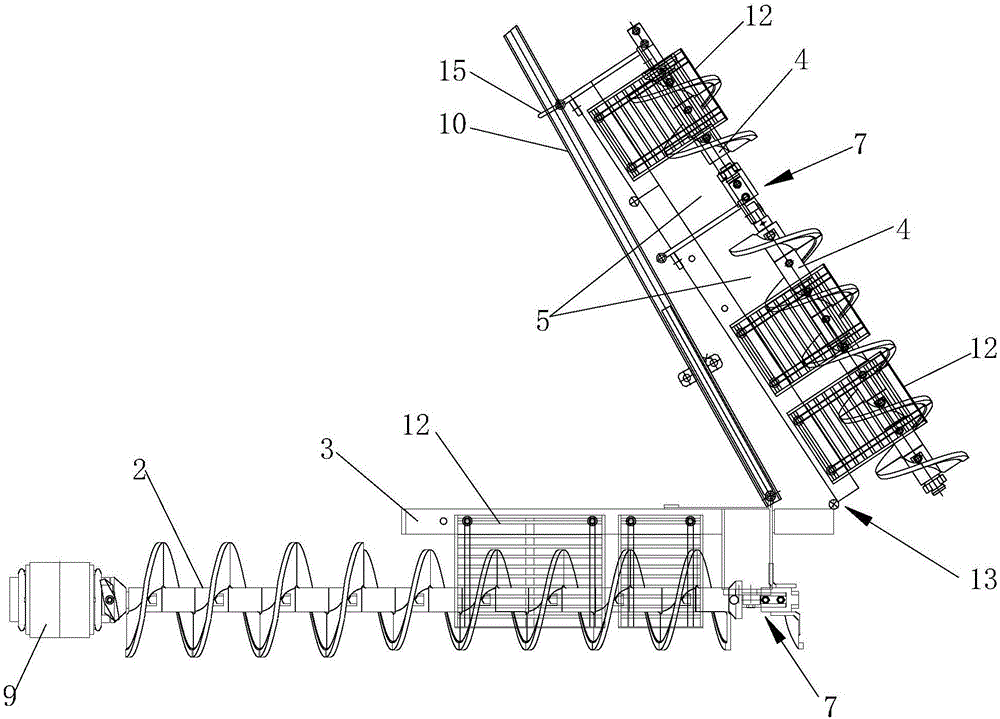

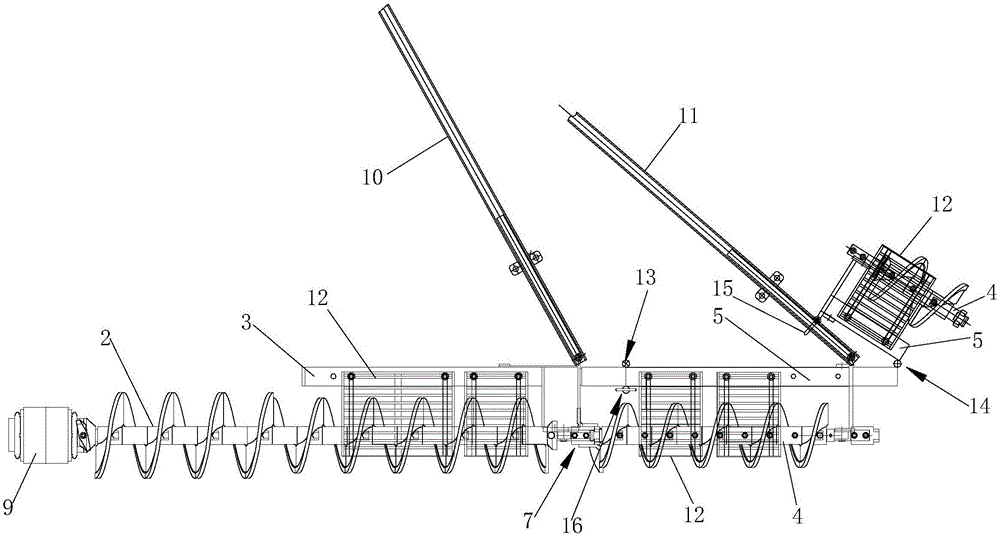

[0061] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown multi-stage folding screw feeding mechanism for a paver includes a first screw shaft 2 arranged on one side of the main machine 1 of the paver and a first stopper located on the front side of the first screw shaft 2 plate 3, and at least two second screw shafts 4 arranged at the end of the first screw shaft 2 away from the main machine 1 of the paver and a second baffle plate 5 corresponding to the second screw shaft 4 one-to-one, the The second material baffle plate 5 is arranged on the front side of the second screw shaft 4 corresponding thereto, the first material baffle plate 3 is hinged to the second material baffle plate 5 adjacent to it, and two adjacent The second baffle plate 5 is hinged, the first screw shaft 2 is connected to the second screw shaft 4 adjacent to it, and the two adjacent second screw shafts 4 are all detachable connections. A baffle plate 3 is provided with a first support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com