Spliced bridging structure and building method thereof

A splicing and connecting structure technology, applied in the field of transportation, can solve the problems of reducing the degree of congestion and abnormal congestion of the horizontal main road, and achieve the effect of reducing traffic congestion, reducing the impact of traffic, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

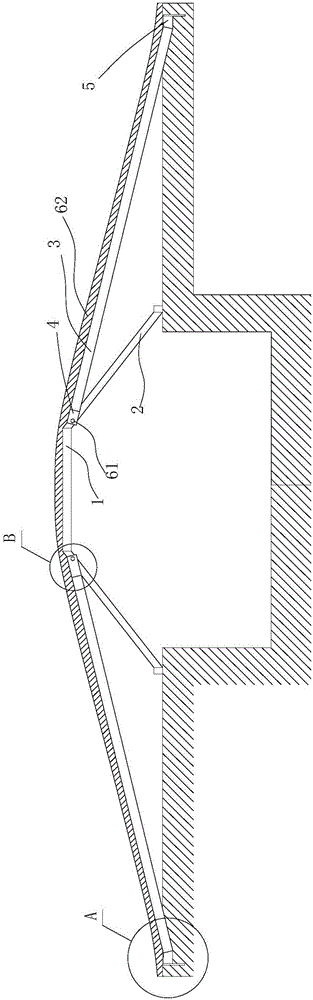

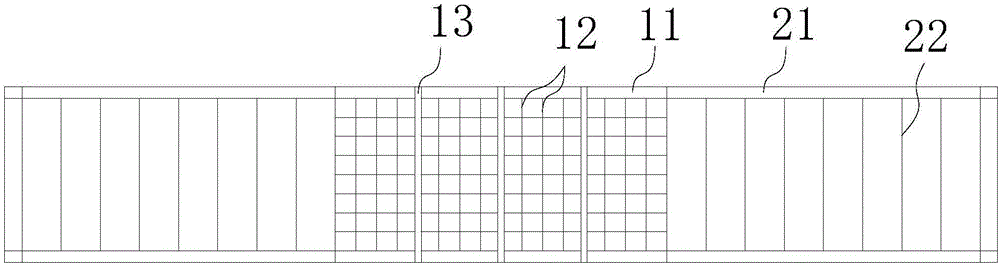

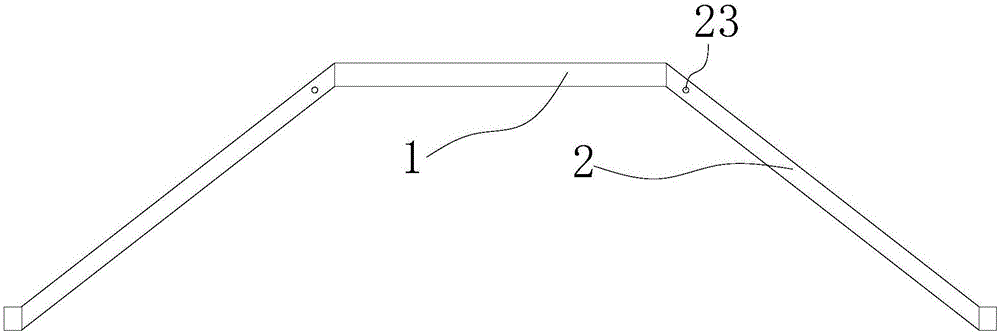

[0023] Such as Figure 1~6 As shown: it includes at least one set of arch bridge structures and slope structures arranged at the front and rear of the arch bridge structures and correspondingly connected with the arch bridge structures. The bridge frame 2 is connected as a whole, and the subgrade section 1 is connected with the bridge frame 2 to form an arch structure. The two ends of the bridge frame 2 are erected on both sides of the passage perpendicular to the arch bridge structure; The force is guided to the ground through the bridge frame. On the other hand, due to the small area of the roadbed section, the sum of the forces exerted by the vehicle on the roadbed section is also small.

[0024] The sloping plate structure includes a slope subgrade section 3 and an overlapping structure 4 arranged on the front side of the slope subgrade section 3. The connection structure 4 is built on the bridge frame 2 and fixedly connected with the bridge frame 2, and the limit struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com