A bridge erection construction method using a 900-ton beam moving machine to load beams on bridge deck beam trucks

A construction method and beam-moving machine technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of capital occupation, increase of company operating costs, waste of resources, etc., to avoid blind investment and reduce the company's financial pressure , The effect of reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

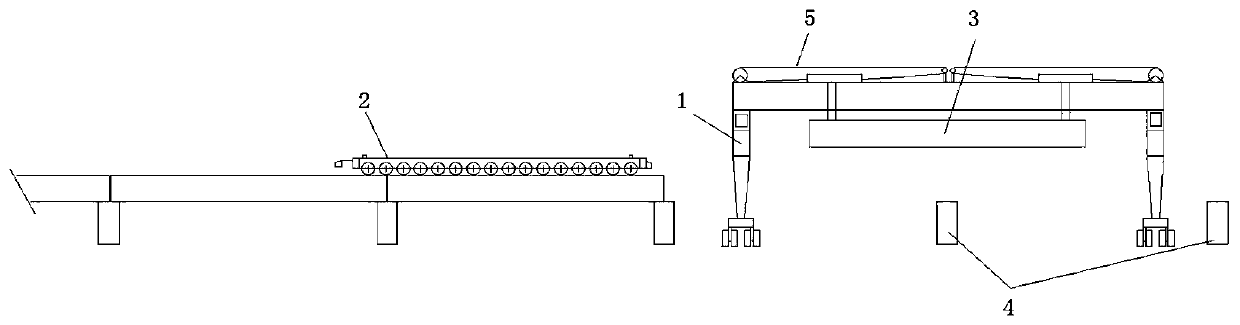

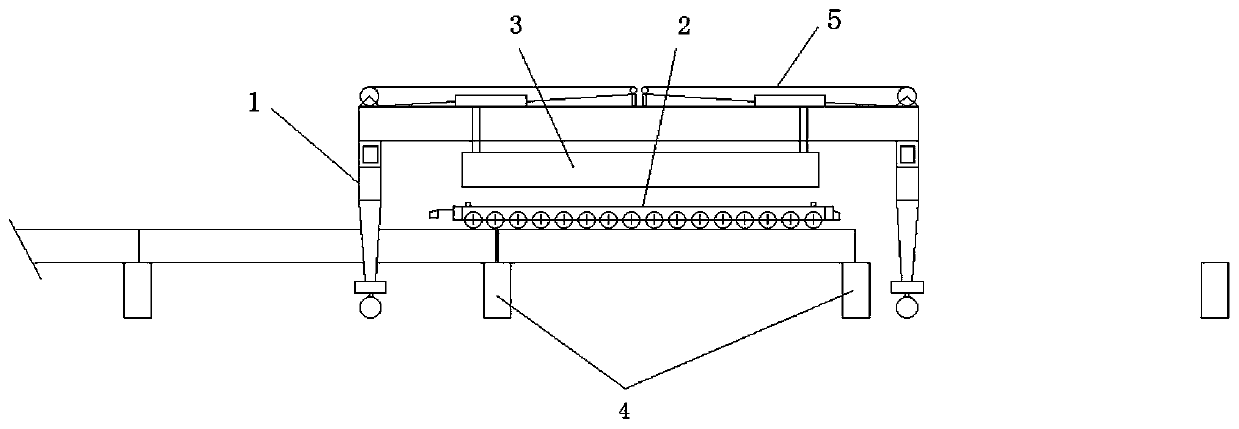

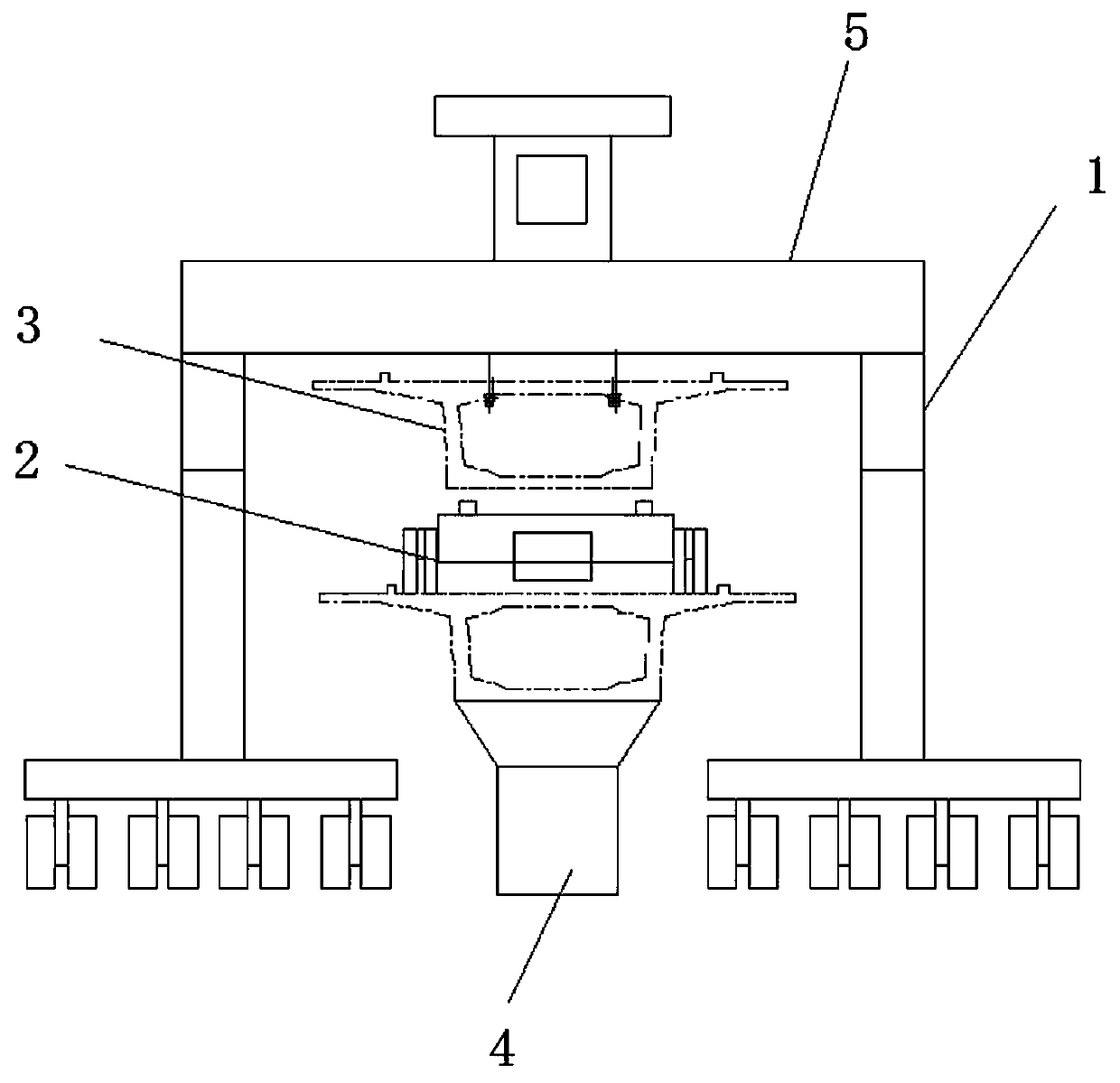

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] In the construction process of high-speed railway bridge erection, when the beam yard is located on the side of the bridge, a set of 900-ton beam shifting machine and two sets of 450-ton beam lifting machine are required to lift the beam to the bridge and load the beam to the beam truck when transporting the beam. In the absence of a 450-ton beam lifting machine, using this bridge erection construction method and the existing 900-ton beam moving machine in the beam yard can conveniently and labor-savingly load beams to the bridge deck beam transport vehicle. Since the height of the existing 900-ton beam-moving machine is not enough, this method first needs to transform the 900-ton beam-moving machine according to the height of the bridge deck, that is, erect the height-increasing joints on the legs of the beam-moving machine, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com