Reinforcement Cage Main Reinforcement Locator and Its Application Method

A reinforcement cage and locator technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., to achieve the effects of avoiding steel reinforcement injuries, shortening processing time, and improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

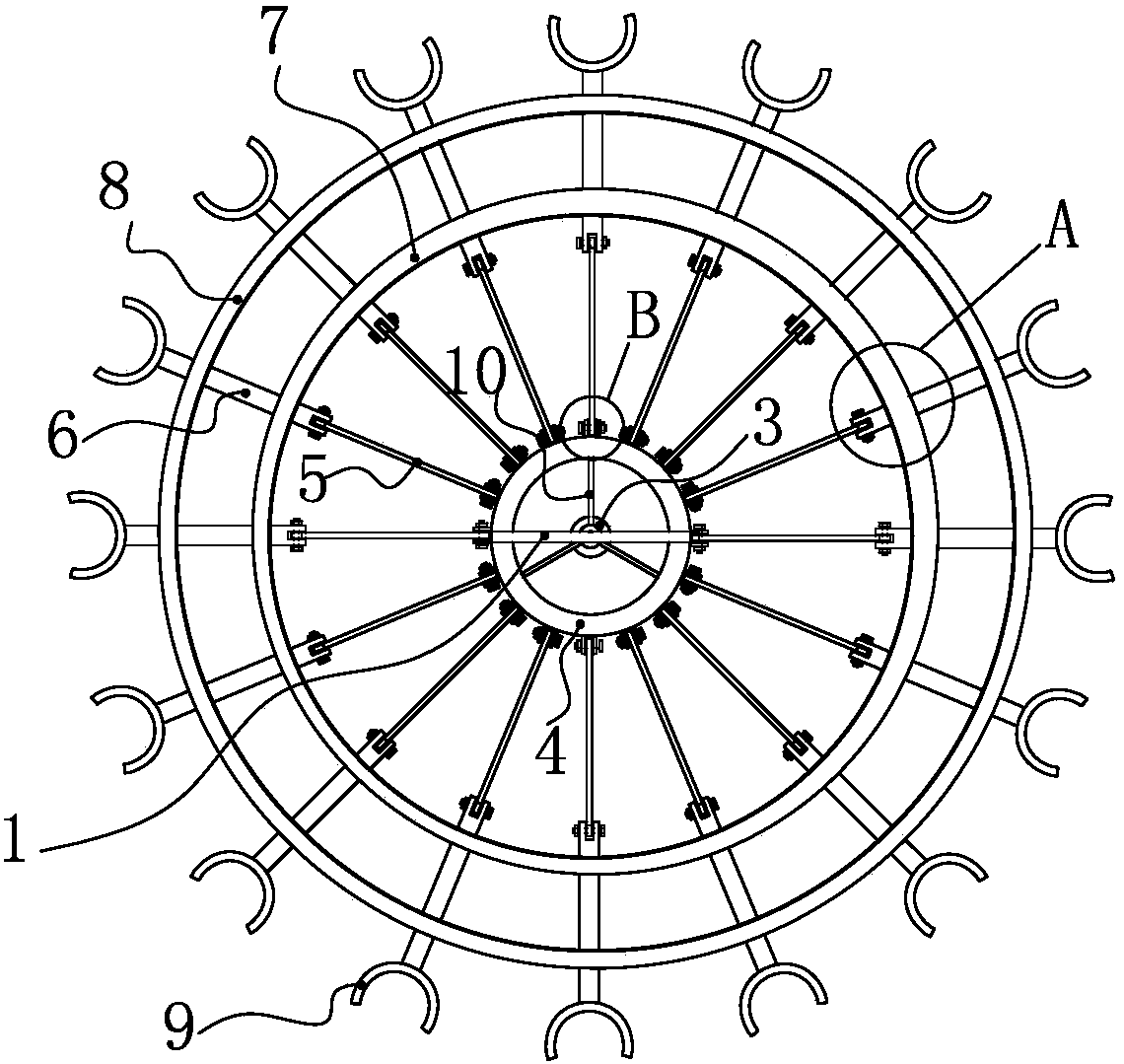

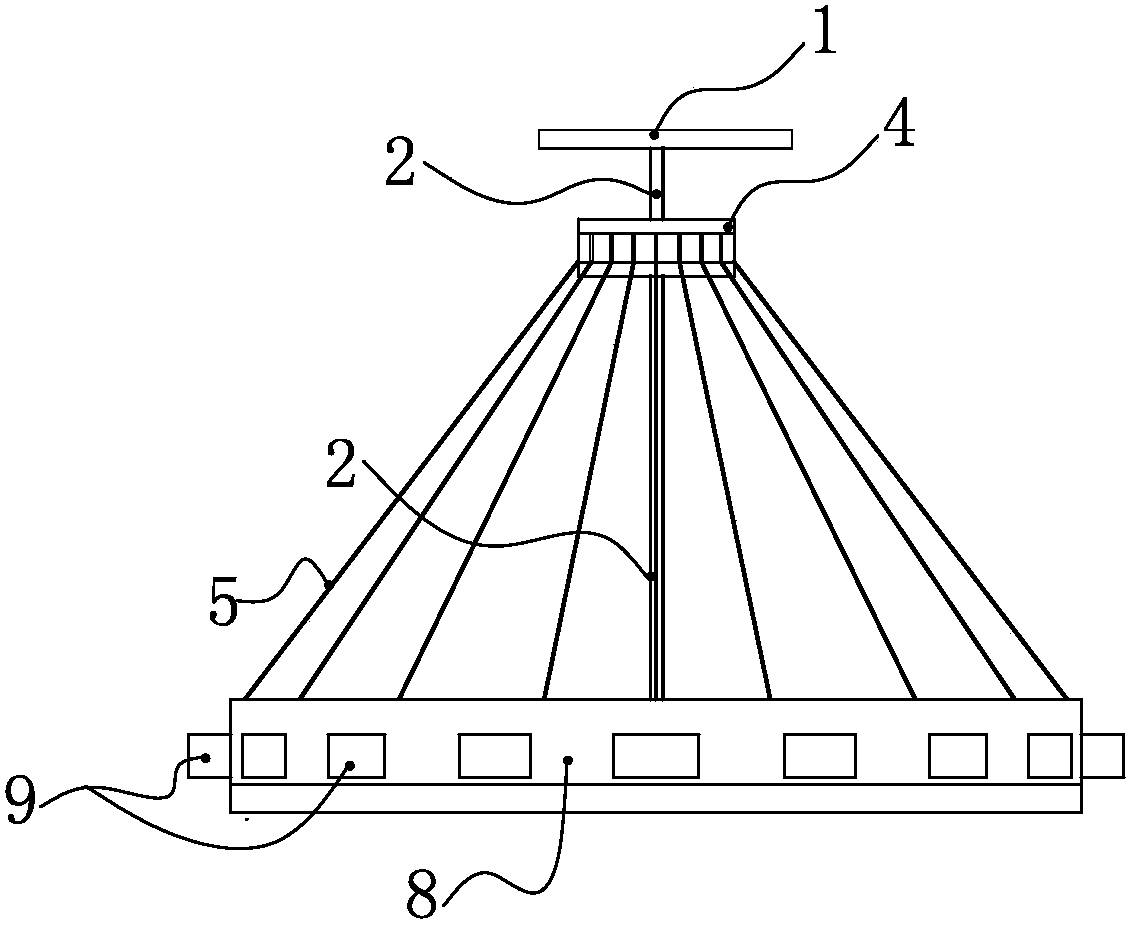

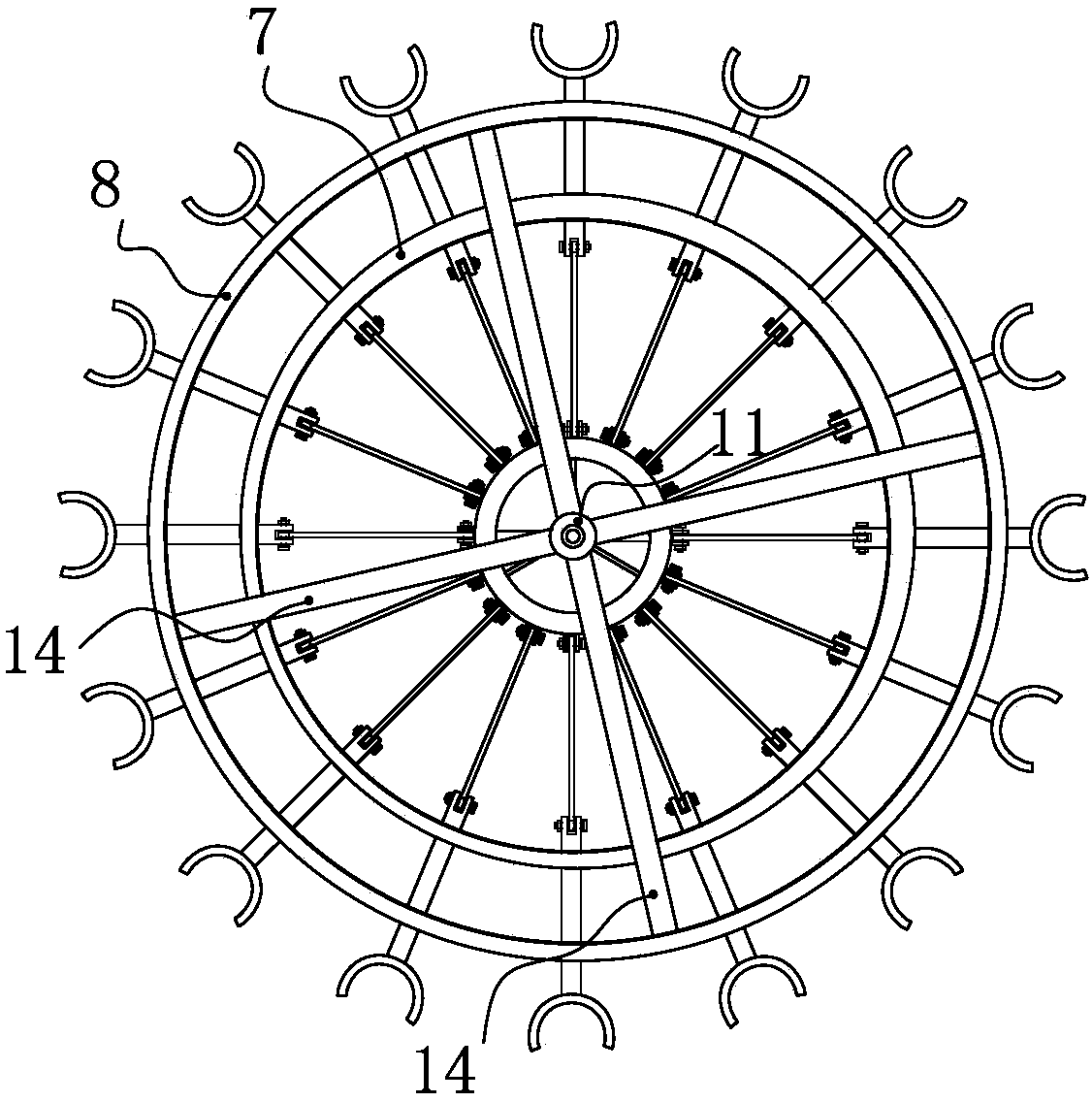

[0026] The following is attached Figure 1-6 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0027] Such as Figure 1-3 As shown, the invention includes an operating handle 1, a lead screw 2, a screw nut 3, an active support ring 4, a support rod 5, a ejector rod 6, an inner support frame 7 for ejector rod positioning, an outer support frame 8 for ejector rod positioning, and a positioning support mold 9. The main reinforcement cage locators are all made of stainless steel.

[0028] The operating handle is located on the top of the locator and is fixedly connected to the top of the lead screw as a whole. The upper part of the lead screw is connected with the screw nut. Turning the operating handle drives the lead screw to rotate to drive the screw nut to move along the lead screw. The operating handle is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com