Sliding mode construction method for subway vehicle depot beam plate concrete structure

A technology for concrete structures and subway depots, which is applied in building construction, processing of building materials, construction, etc. It can solve problems such as high foundation bearing capacity and flatness requirements, high rental fees and labor costs, and long waiting times for processes. , to improve safety, reduce construction costs, and avoid frame instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] Construction preparations include routine construction preparations such as surveying and positioning, construction machinery and equipment, materials, temporary facilities, labor, technical disclosure, and pre-job training.

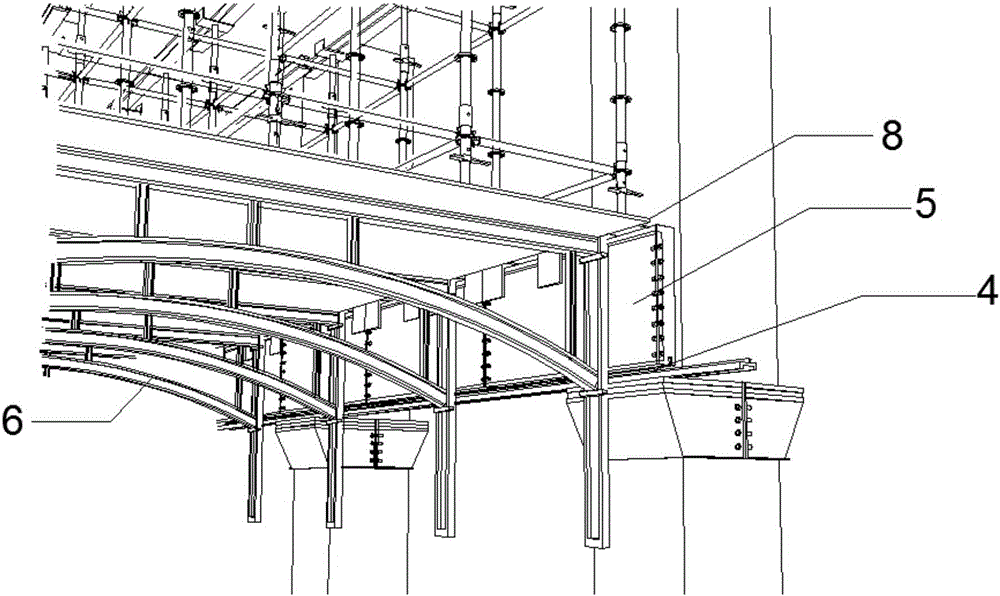

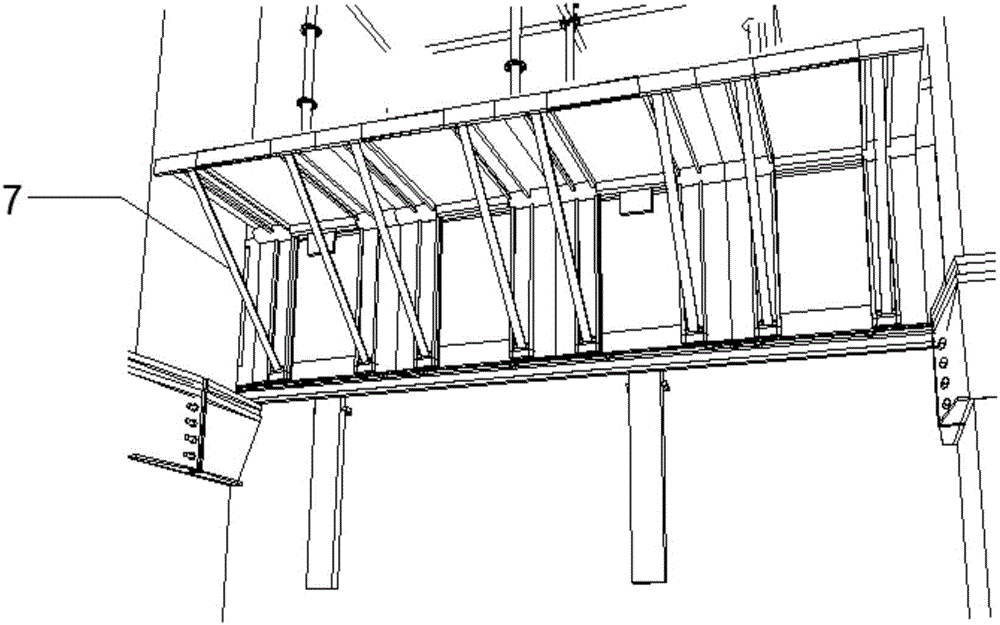

[0040] The specific construction steps of the slipform construction of the main structure of the subway depot are as follows:

[0041] (1) Construction of concrete frame columns

[0042] After completing the support of column reinforcement and frame column formwork, and passing the inspection and acceptance of the supervisor, the frame column concrete is poured one by one, and the frame column formwork is removed after 24 hours, and the film is covered and cured to 100% strength.

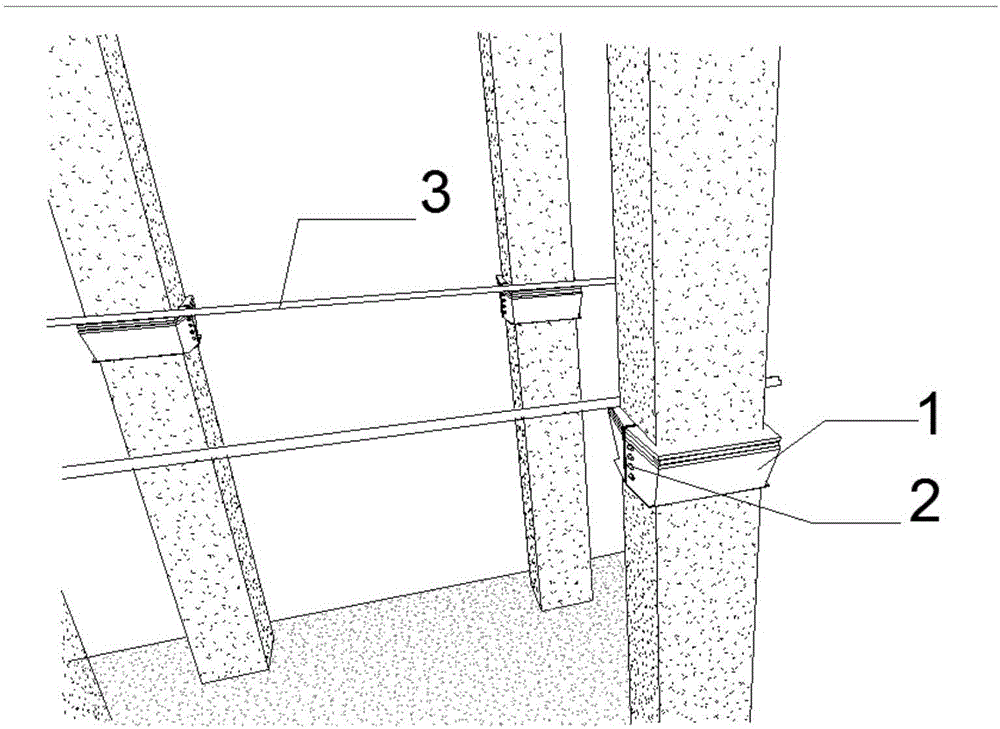

[0043] (2) Install steel corbels

[0044] see figure 1 , brush the interface agent within the frame column steel corbel installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com