Steam injection, air injection and production well gas-fire stimulation combined oil extraction method

A gas-fired huff and puff technology for production wells, which is applied in the fields of steam injection combined with air injection and gas-fired huff and puff oil production in production wells, and can solve problems such as uneven effectiveness, low air flooding efficiency, and single gas injection inrush.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

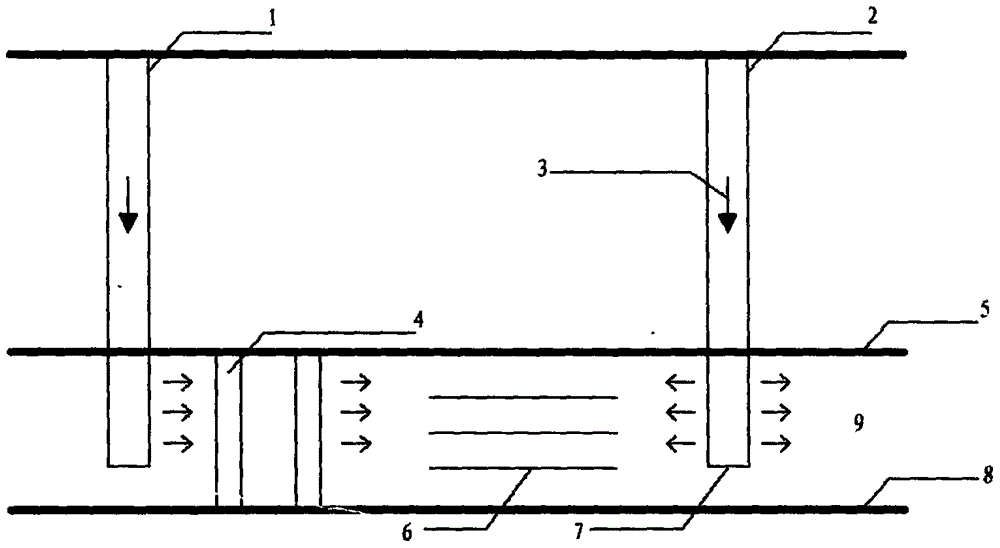

[0025] A steam injection combined with air injection and production well gas huff and puff oil recovery method, comprising: 1. According to the requirements of gas injection at high positions and oil production at low positions, the gas injection wells (1 ) and production wells (2) for well layout; 2. Carry out high-pressure gas injection completion for the gas injection well (1), inject 260 tons of 280°C high-temperature steam into the gas injection well (1) to increase the temperature of the formation, and establish a temperature field, After the formation is warmed up and preheated, air is injected into the gas injection well (1) for ignition, and the air flooding oil production starts; 3. After 3 months of the air flooding oil production, the production well (2) gas fire huff and puff (7) process starts: First inject 100 tons of 130°C high-temperature hot water into the production well (2), and then inject 150,000 cubic meters of air according to the formation parameters. A...

Embodiment 2

[0027] A steam injection combined with air injection and production well gas huff and puff oil recovery method, comprising: 1. According to the requirements of gas injection at high positions and oil production at low positions, the gas injection wells (1 ) and production wells (2) for well layout; 2. Carry out high-pressure gas injection completion for the gas injection well (1), inject 200 tons of 300°C high-temperature steam into the gas injection well (1) to increase the temperature of the formation, and establish a temperature field, After the formation is warmed up and preheated, air is injected into the gas injection well (1) for ignition, and the air flooding oil production starts; 3. After 3 months of the air flooding oil production, the production well (2) gas fire huff and puff (7) process starts: First inject 80 tons of 150°C high-temperature hot water into the production well (2), and then inject 200,000 cubic meters of air according to the formation parameters. Af...

Embodiment 3

[0029] A steam injection combined with air injection and production well gas huff and puff oil recovery method, comprising: 1. According to the requirements of gas injection at high positions and oil production at low positions, the gas injection wells (1 ) and production wells (2) for well layout; 2. Carry out high-pressure gas injection completion for the gas injection well (1), inject 180 tons of 320°C high-temperature steam into the gas injection well (1) to increase the temperature of the formation, and establish a temperature field, After the formation is warmed up and preheated, air is injected into the gas injection well (1) for ignition, and the air flooding oil production starts; 3. After 3 months of the air flooding oil production, the production well (2) gas fire huff and puff (7) process starts: First inject 80 tons of 150°C high-temperature hot water into the production well (2), and then inject 300,000 cubic meters of air according to the formation parameters. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com