Actuating cylinder with mechanical lock arranged inside and locking and unlocking methods of actuating cylinder with mechanical lock arranged inside

A technology for actuators and mechanical locks, applied in the direction of fluid pressure actuation devices, etc., can solve the problems of increased space size, more sealing links, complexity and weight of actuators, etc., to reduce weight and reduce sealing links , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

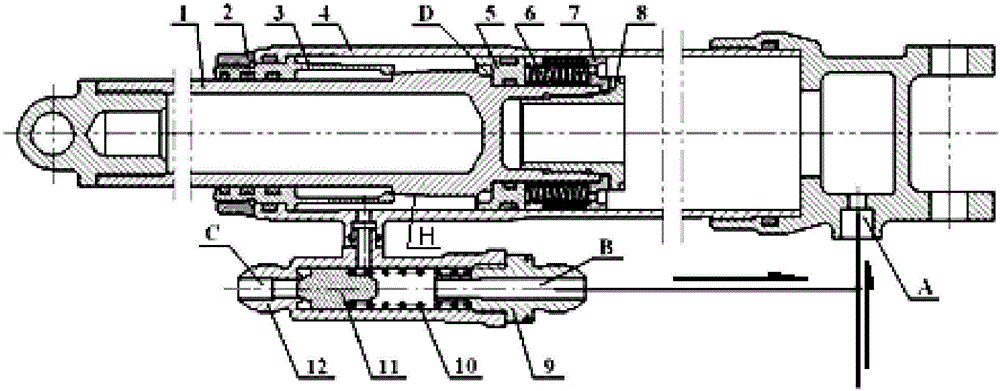

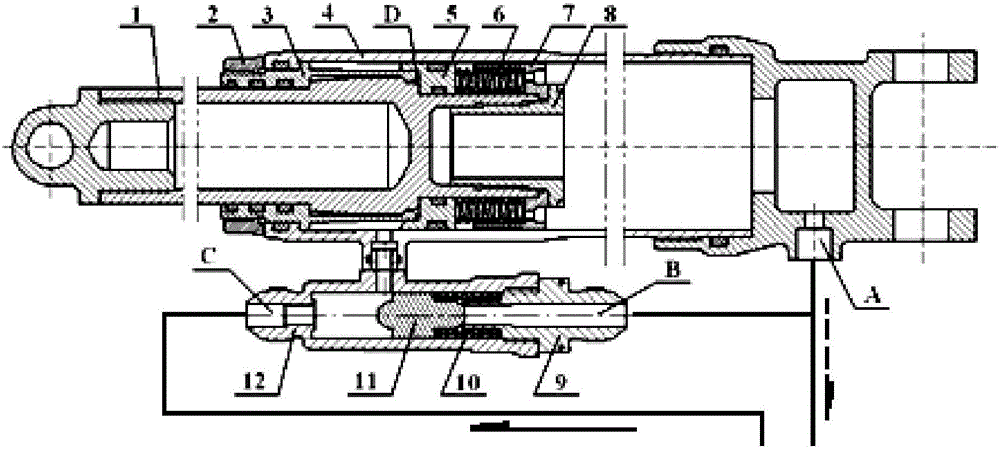

[0035] A differentially controlled built-in mechanical lock actuator such as Figure 1-Figure 2 As shown, it consists of the main body of the actuator and the shuttle valve. The main body of the actuator includes parts such as a piston rod 1, an elastic locking pawl 3, an outer cylinder 4, a traveling piston 5 and a retainer 7. The outer surface of the piston rod 1 is an outer cone surface, and the elastic locking claw 3 locks and unlocks along the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com