A radial sliding bearing pair with circulating self-drainage and self-closing lubricating oil film

A lubricating oil film and radial sliding technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of carbon deposits or other dregs, lubricating oil film damage, etc., to maintain the lubricating effect, reduce Frictional loss, the effect of prolonging the time period of trouble-free operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

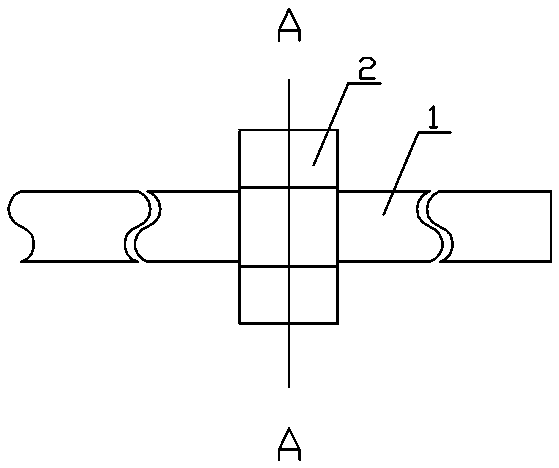

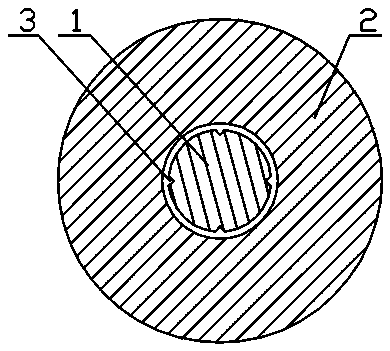

[0024] In this example, if image 3 As shown, a radial sliding bearing pair with circulating self-draining and self-distributing lubricating oil film has a journal 1 and a bearing 2 matching with the journal 1. There are two obliquely arranged grooves 3 evenly arranged around the circumference, and both ends of the grooves 3 protrude from the matching area between the journal 1 and the bearing 2. In terms of the arrangement of the grooves 3, the inclination direction between adjacent grooves 3 unanimous.

Embodiment 2

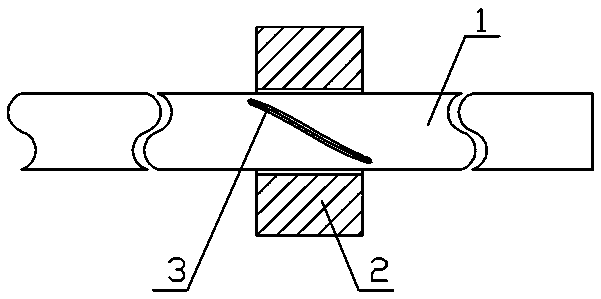

[0026] In this example, if Figure 4 As shown, a radial sliding bearing pair with circulating self-draining and self-distributing lubricating oil film has a journal 1 and a bearing 2 matching with the journal 1. There are two obliquely arranged grooves 3 in one week, and both ends of the grooves 3 protrude from the matching area between the journal 1 and the bearing 2. In terms of the arrangement of the grooves 3, the two grooves 3 intersect and form a " The X"-shaped cross is arranged on the journal 1, and the other two grooves 3 are symmetrically arranged on the other side of the journal 1.

Embodiment 3

[0028] In this example, if Figure 5 As shown, a radial sliding bearing pair with circulating self-draining and self-distributing lubricating oil film has a journal 1 and a bearing 2 matching with the journal 1. There are two oblique and parallel grooves 3 evenly arranged around the circumference, and the inclination directions of the protruding ends of each groove 3 are the same. One end of the groove 3 protrudes from the matching area between the journal 1 and the bearing 2, and the other end is located In the matching area with the bearing 2 , the inclination direction of the groove 3 is opposite to the rotation direction of the journal 1 .

[0029] In this embodiment, two adjacent grooves can also be arranged obliquely and staggered, see Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com