Thread gap elimination device and assembly method thereof

A thread clearance and clearance technology, which is applied to transmissions, transmission parts, belts/chains/gears, etc., can solve the problems of troublesome installation, increased equipment cost, and high manufacturing cost, and achieves simple structure, convenient installation, and elimination of thread clearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

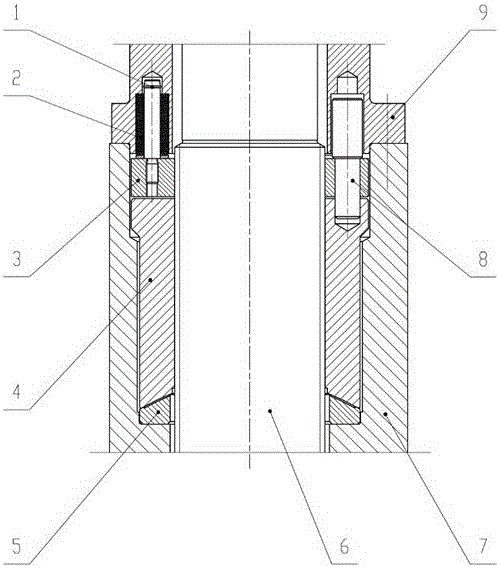

[0022] Such as figure 1 As shown, a thread gap eliminating device of the present invention comprises a transmission screw rod 6, a main nut 4, an auxiliary nut 3, a connecting pin 8, a disc spring pin 1, a disc spring 2, a casing 7, an end cover 9; 9 is fixed on the top of the box body 7 by fasteners, the transmission screw rod 6 passes through the center hole of the box body 7 and the end cover 9, and is set between the inner hole of the box body 7 and the radial direction of the transmission screw rod 9 There are main nut 4 and auxiliary nut 3, the main nut 4 and auxiliary nut 3 are fitted on the external thread of the transmission screw 9 through the internal thread, and there is a certain gap with the inner hole of the box body 7, the auxiliary nut 3 is arranged on the main nut 4, there is a certain gap between the two, the connecting pin 8 connects the end cover 9, the auxiliary nut 3 and the main nut 4, the lower part of the disc spring pin 1 is connected to the auxiliar...

Embodiment 2

[0024] In the above embodiment, the outer diameter of the lower boss of the end cover 9 matches the inner hole of the top of the box body 7 , and its shoulder contacts the upper end surface of the box body 7 .

Embodiment 3

[0026] The inner holes on the lower end surface of the end cover 9 are several stepped blind holes, the depth of the large holes is determined according to the working height of the disc spring 2, the diameter of the large holes is slightly larger than the outer diameter of the disc spring 2, and the upper part of the connecting pin 8 The outer diameter of the large diameter section is slightly smaller than the diameter of the large hole.

[0027] When determining the size of the large hole in the stepped blind hole on the lower end face of the end cover 9, the design sequence is: A. Determine the size of the disc spring 2 according to the force and structural requirements; B. Design the end according to the size of the selected disc spring 2 The size of the large hole section in the inner hole of the lower end surface of the cover 9; C. design the size of the large diameter section on the top of the connecting pin 8 according to the size of the large hole section in the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com