Valve leakage testing system and valve leakage testing method based on infrared thermal imaging technology

A technology of infrared thermal imaging and infrared thermal imager, which is applied in the direction of fluid tightness testing, machine/structural component testing, measuring devices, etc., can solve the problems of low detection accuracy and easy safety accidents, and achieve considerable promotion prospects , Eliminate false leakage interference, avoid safety hazards and accuracy defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

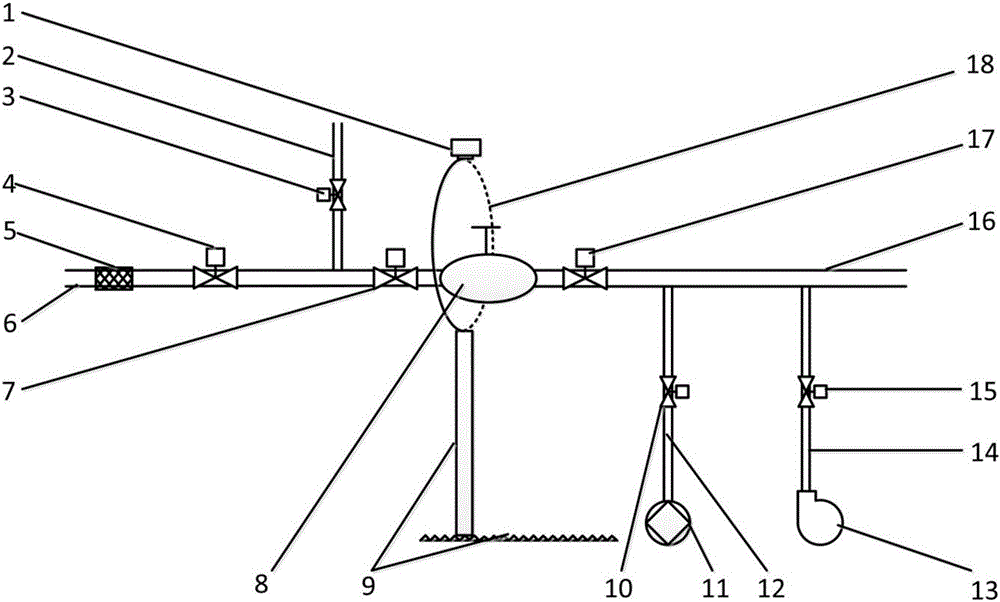

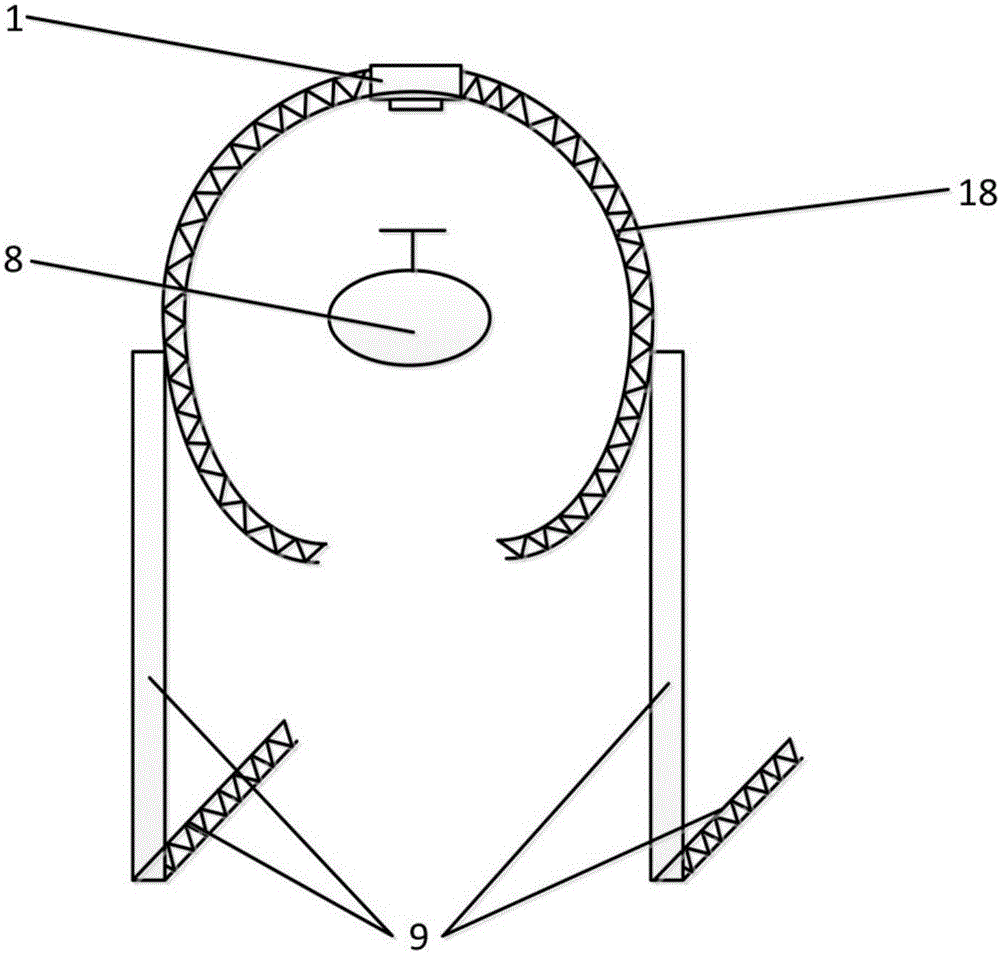

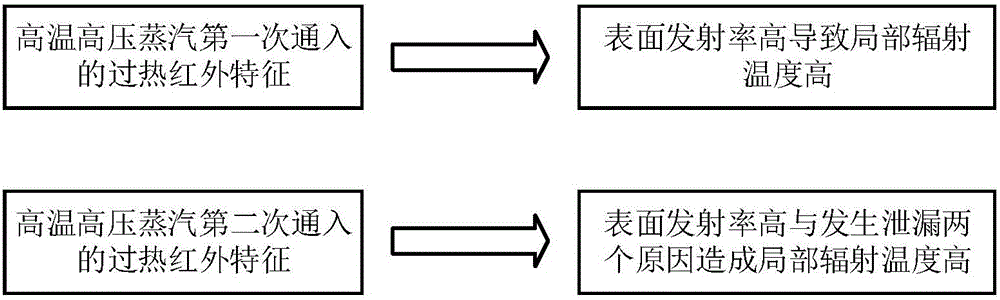

[0015] according to figure 1 Fixing equipment is installed, and the infrared thermal imager 1 is fixed on the circular slide rail 18, and the circular slide rail 18 is fixed on the horizontal slide rail 9 by a vertical fixing rod. Carry out the first heating process, open the exhaust steam valve 4, the first ball valve 7, and the second ball valve 17, the valve 8 to be checked is in the open state, and the other valves are in the closed state, and the high temperature and high pressure water vapor inlet pipe 16 is continuously introduced into the high temperature High-pressure water vapor, high-temperature and high-pressure water vapor is discharged from the exhaust pipe 6 through the valve 8 to be inspected and the filter device 5. The filter device 5 plays the role of filtering impurities in the steam during the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap