An automobile longitudinally set composite material plate spring performance testing device

A composite material board and testing device technology, which is applied in the direction of measuring devices, elastic testing, mechanical parts testing, etc., can solve the problem of poor versatility of testing tooling, increase of leaf spring R&D, maintenance, maintenance costs, and the inability of leaf springs to accurately measure boards Problems such as the change value of the center distance of the lifting lug, etc., achieve the effect of simple structure and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

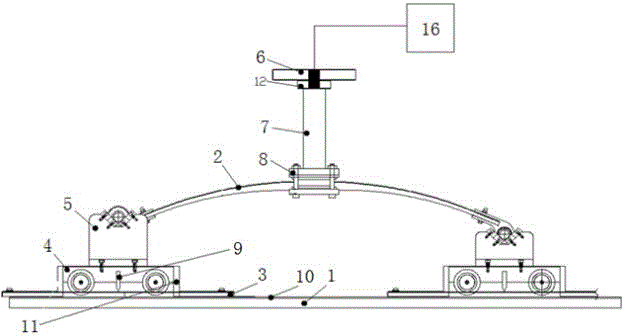

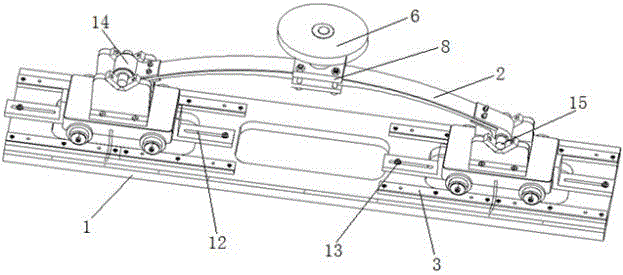

[0030] Such as figure 1 , 2 , a performance test device for longitudinal composite leaf springs of automobiles, comprising a base plate 1 and a plate spring 2 to be tested, the top surface of the base plate 1 is a test reference plane, and a pair of guide rails are symmetrically arranged on both sides of the top surface of the base plate 1 3. A pair of sliders 4 are provided on the guide rail 3, and a support member 5 for positioning the end of the leaf spring 2 to be tested is fixed on the slider 4. A moving pair is formed between the guide rail 3 and the slider 4 and is provided with The matching displacement measuring device can measure the displacement at both ends of the leaf spring through the displacement measuring device;

[0031] The output rod 7 of the load loading system 6 used to pressurize the leaf spring 2 to be tested is connected to the middle part of the leaf spring 2 to be tested by a splint 8, the central axis of the output rod 7 is perpendicular to the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com