Industrial process fault detection method based on correction type independent element analysis and Bayes probability fusion

A technology of independent element analysis and fault detection, applied in the testing, measuring devices, instruments, etc. of machine/structural components, can solve the problems of reducing the accuracy and reliability of fault detection methods, model uncertainty, etc., to reduce the dependence , enhance reliability, increase the effect of reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

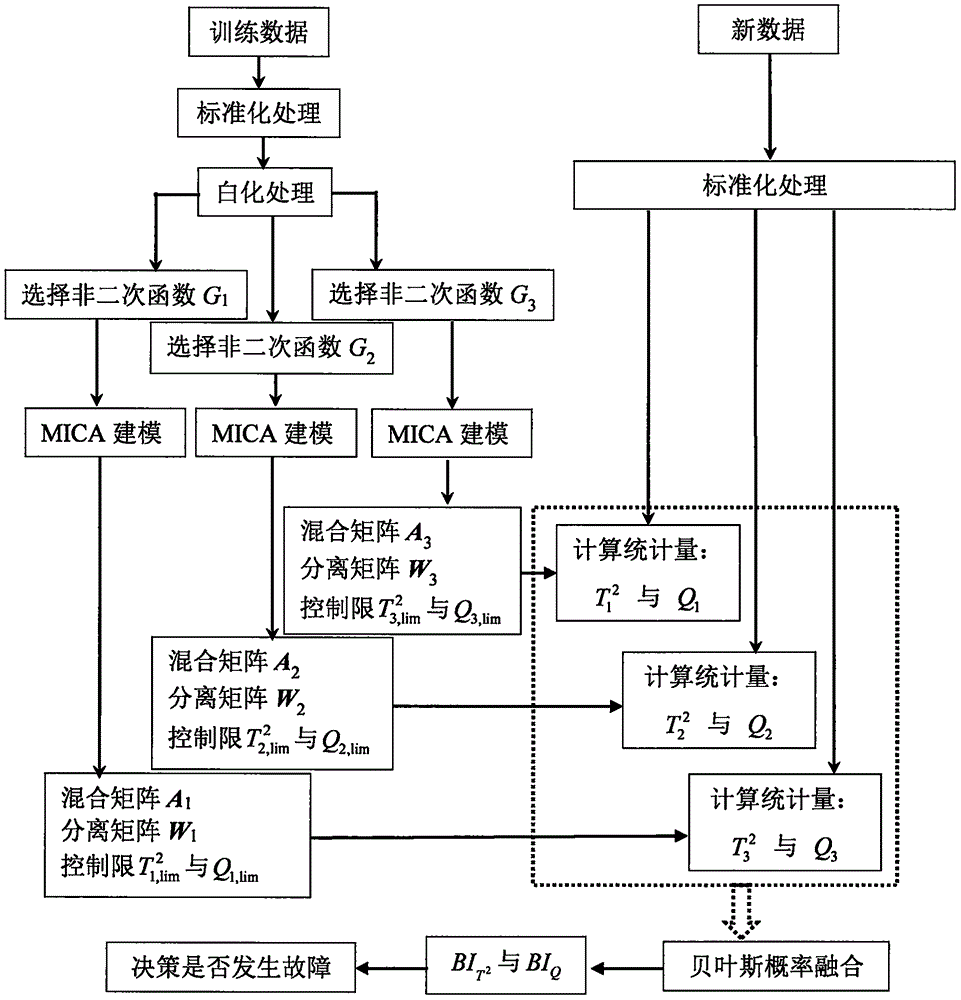

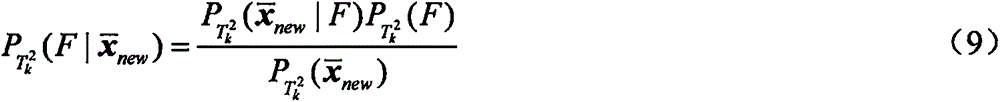

[0017] As shown in Fig. 1, the present invention discloses an industrial process fault detection method based on modified independent element analysis and Bayesian probability fusion. Aiming at the problem of industrial process fault detection, firstly, the data collection system is used to collect the data set under the normal operation state of the production process and standardize it. Secondly, the corresponding MICA fault detection model is established for different non-quadratic functions, and the model parameters are saved for future use. Then, three sets of different monitoring statistics T are calculated for the new sampling data 2 and Q, and use the Bayesian probability fusion method to integrate different monitoring results into probability indicators. Finally, monitor metrics based on probability with BI Q Whether the specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com