Imaging system of lithium battery pole piece surface defect detection device and using method of imaging system

An imaging system and defect detection technology, which is applied in the field of imaging systems, can solve the problems of secondary damage to pole pieces, cumbersome detection process, and heavy workload, and achieve the effects of improved detection accuracy, simple operation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

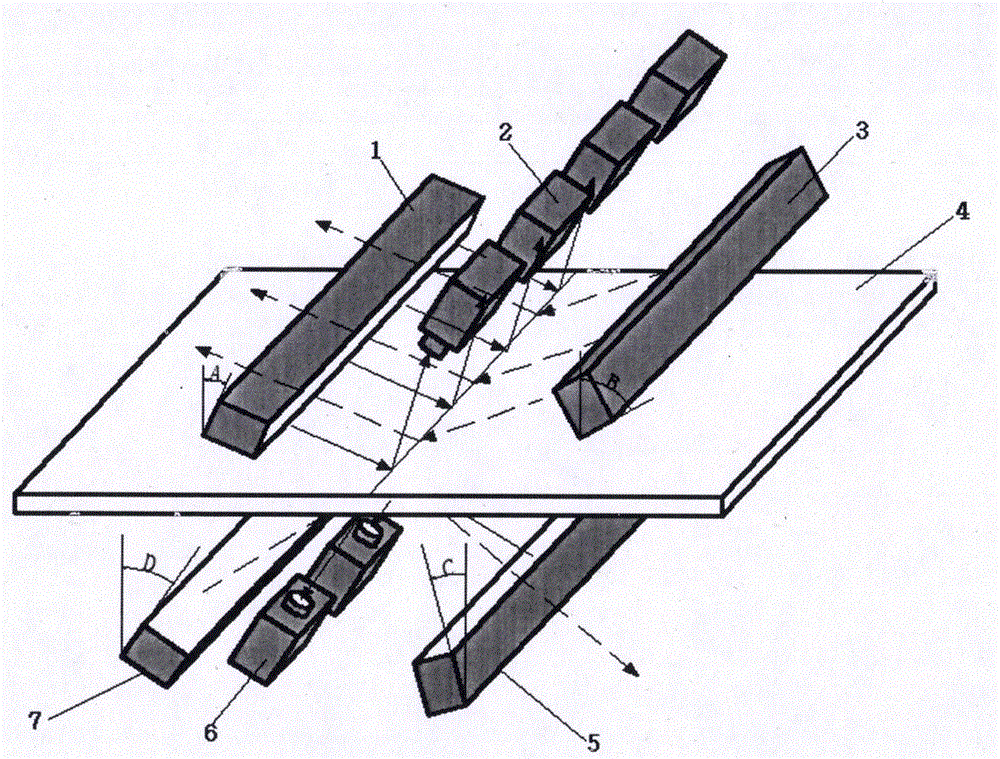

[0023] Embodiment 1: as figure 1 Shown is the imaging system of the lithium battery pole piece surface defect detection device. It can be seen from the figure that the imaging system includes an upper acquisition and detection device placed above the upper surface of the tested pole piece, including a first LED light source 1, a second LED light source 3 and The first line array camera 2; the first LED light source 1 has an inclination angle of 20° relative to the normal line on the plane of the tested pole piece, and its light is reflected by the upper surface of the tested pole piece 4, and the reflected light enters the described pole piece. The main optical axis of the first line array camera lens of the imaging system to form a bright field environment; the first line array camera 2 adjusts the lens to just receive the reflected light of the first LED light source; the second LED light source 3 and the second LED light source Line-array cameras 2 are all above the pole pi...

Embodiment 2

[0034] Embodiment 2: as figure 1Shown is the imaging system of the lithium battery pole piece surface defect detection device. It can be seen from the figure that the imaging system includes an upper acquisition and detection device placed above the upper surface of the tested pole piece, including a first LED light source 1, a second LED light source 3 and The first line array camera 2; the first LED light source 1 has an inclination angle of 30° relative to the normal line on the plane of the tested pole piece, and its light is reflected by the upper surface of the tested pole piece 4, and the reflected light enters the described pole piece. The main optical axis of the first line array camera lens of the imaging system to form a bright field environment; the first line array camera 2 adjusts the lens to just receive the reflected light of the first LED light source; the second LED light source 3 and the second LED light source The line-array cameras 2 are all above the pole...

Embodiment 3

[0045] Embodiment 3: as figure 1 Shown is the imaging system of the lithium battery pole piece surface defect detection device. It can be seen from the figure that the imaging system includes an upper acquisition and detection device placed above the upper surface of the tested pole piece, including a first LED light source 1, a second LED light source 3 and The first line array camera 2; the first LED light source 1 has an inclination angle of 40° relative to the normal line on the plane of the tested pole piece, and its light is reflected by the upper surface of the tested pole piece 4, and the reflected light enters the described pole piece. The main optical axis of the first line array camera lens of the imaging system to form a bright field environment; the first line array camera 2 adjusts the lens to just receive the reflected light of the first LED light source; the second LED light source 3 and the second LED light source The line-array cameras 2 are all above the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com