Control method for automatically heating liquid crystal screen in low-temperature environment

A technology of automatic heating control and low temperature environment, which is applied in nonlinear optics, instruments, optics, etc., and can solve problems such as complex processes and lower reliability of LCD screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

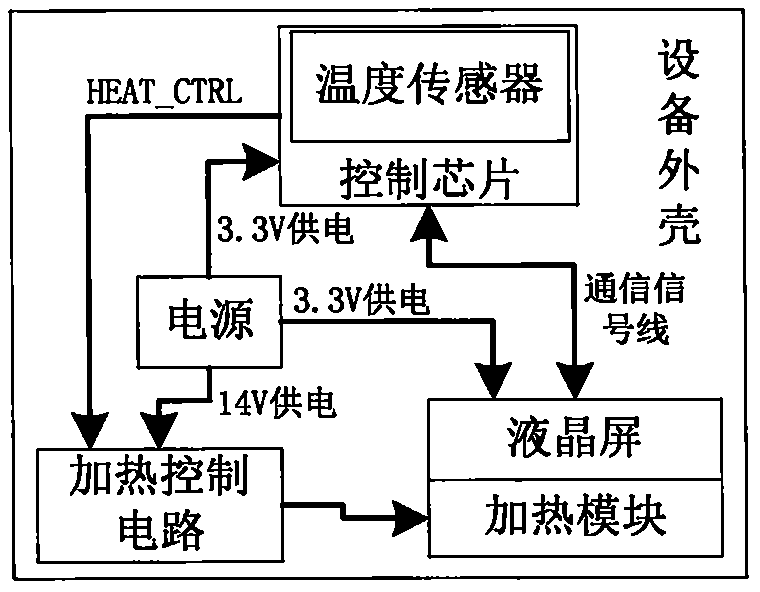

[0019] like figure 1 As shown, the low-temperature Han Jingxia's liquid crystal screen automatic heating control system provided in this embodiment includes: a control chip, a liquid crystal screen, a heating control circuit, and a heating module. details as follows:

[0020] The control chip has a built-in temperature acquisition sensor, and is also provided with a heating control signal output pin (HEAT_CTRL pin in the figure), and the control chip controls the display content of the LCD screen (communication signal line in the figure). The built-in temperature sensor has an accuracy of ±2°C, which can accurately read the temperature value inside the device casing.

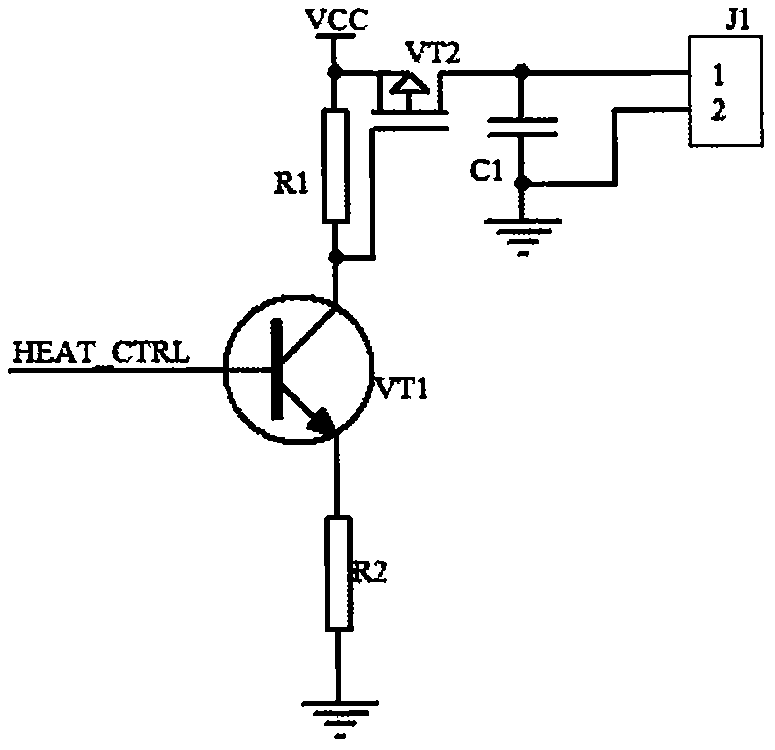

[0021] like figure 2 As shown, the heating control circuit includes a control signal receiving terminal HEAT_CTRL, a power supply terminal VCC, a transistor VT1, a MOS transistor VT2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com