Materials failure analysis method

A material failure and analysis method technology, applied in the field of materials, can solve the problems that it is difficult to apply other technical fields, the data is not disclosed to the public, and the efficiency of material failure analysis is low, and the effect of improving the analysis efficiency and analysis level is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

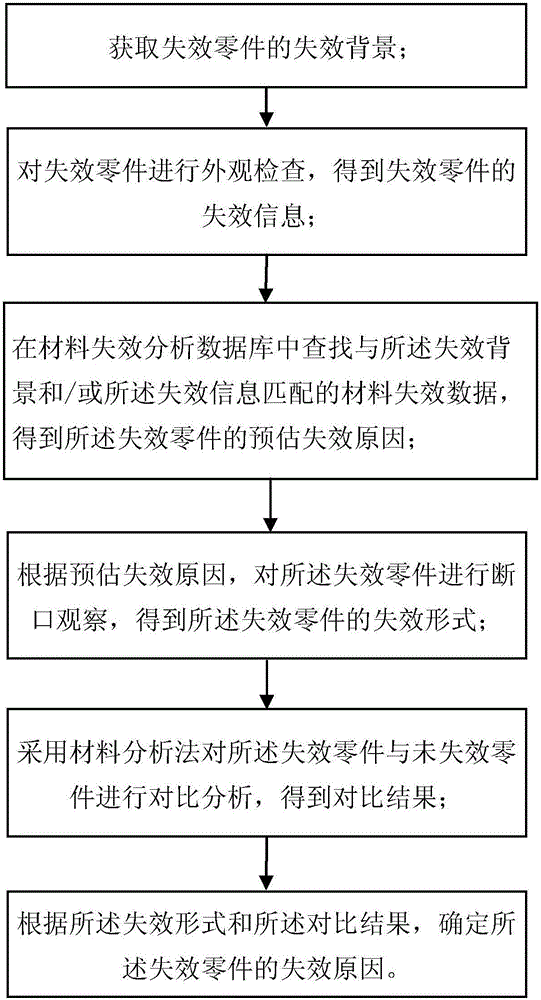

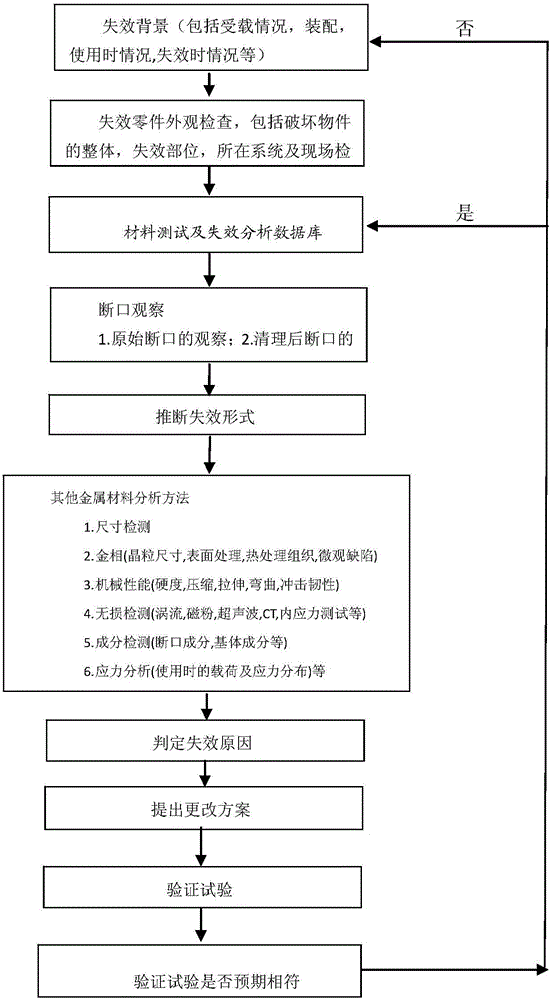

[0020] figure 1 A flow chart of a material failure analysis method is shown, and the material failure analysis method includes the following steps:

[0021] Obtain the failure context of the failed part;

[0022] Carry out visual inspection of the failed parts to obtain the failure information of the failed parts;

[0023] Searching the material failure data matching the failure background and / or the failure information in the material failure analysis database to obtain the estimated failure cause of the failure part;

[0024] Observing the fracture of the failed part according to the estimated failure cause to obtain the failure form of the failed part;

[0025] Using the material analysis method to compare and analyze the failed parts and non-failed parts, and obtain the comparison results;

[0026] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com