Nuclear waste packaging device

A nuclear waste and packaging technology, applied in nuclear engineering, radioactive purification, etc., can solve problems such as microcracks, endangering the personal safety of staff, and poor corrosion resistance, so as to block the leakage of radionuclides, ensure safety and reliability, and prepare The effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

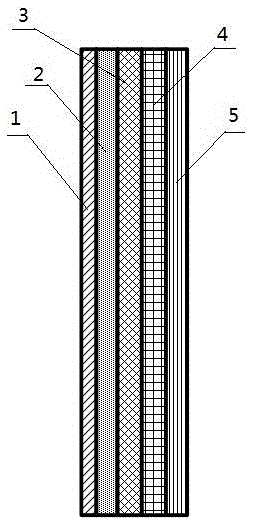

[0028] A nuclear waste packaging device, the radiation shielding packaging layer of the packaging device is multi-layered, including an inner packaging container layer 1, a lead alloy layer 2, a radiation-proof concrete layer 3, an outer packaging container layer 4, Waterproof cover layer 5, the thickness of the inner packaging container layer is 3cm, the thickness of the lead alloy layer is 3.1cm, the thickness of the radiation-proof concrete layer is 7cm, the thickness of the outer packaging container layer is 4cm, and the thickness of the waterproof cover layer is 1.6cm. cm.

[0029] The inner packaging container layer is composed of nuclear grade stainless steel, the chemical composition of which is: C: 0.013%, Si: 0.05%, Mn: 0.1%, P: ≤0.020%, S: ≤0.020%, Cr: 14.3%, Ni: 1.72%, Mo: 0.39%, W: 0.46%, V: 0.06%, Nb: 0.045%, N: 0.0013%, Co: 0.004%, Cu: 0.0035%, the rest is Fe and not Avoid impurities; the preparation method of the stainless steel is: (1) smelting: molten iron i...

Embodiment 2

[0035] A nuclear waste packaging device, the radiation shielding packaging layer of the packaging device is multi-layered, including an inner packaging container layer 1, a lead alloy layer 2, a radiation-proof concrete layer 3, an outer packaging container layer 4, Waterproof cover layer 5, the thickness of the inner packaging container layer is 3cm, the thickness of the lead alloy layer is 3cm, the thickness of the radiation-proof concrete layer is 6cm, the thickness of the outer packaging container layer is 4cm, and the thickness of the waterproof cover layer is 1.5cm .

[0036] The inner packaging container layer is composed of nuclear grade stainless steel, the chemical composition of which is: C: 0.01%, Si: 0.3%, Mn: 0.4%, P: 0.01%, S: 0.01%, Cr: 15.6%, Ni: 1.72%, Mo: 0.39%, W: 0.33%, V: 0.066%, Nb: 0.037%, N: 0.0015%, Co: 0.0024%, Cu: 0.0014%, the rest is Fe and unavoidable impurity; the preparation method of the stainless steel is: (1) smelting: smelting the molten ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com