Method for the continuous thermal hydrolysis of sludge with a high dryness value

一种热水解、污泥的技术,应用在水/污泥/污水处理、通过温度控制污泥处理、水/污水处理等方向,能够解决发动机能量消耗增加、难以实施、磨损等问题,达到能量消耗减半、节省能量、降低压降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

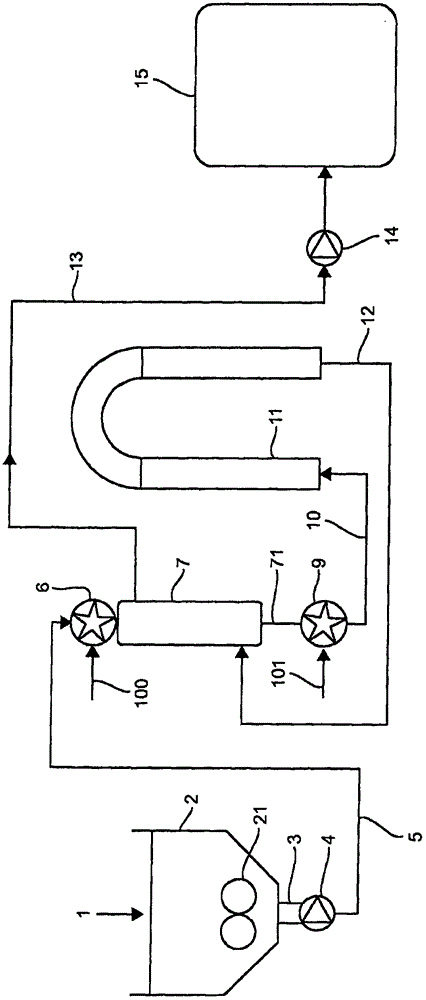

[0072] 6. Description of Embodiments of the Invention

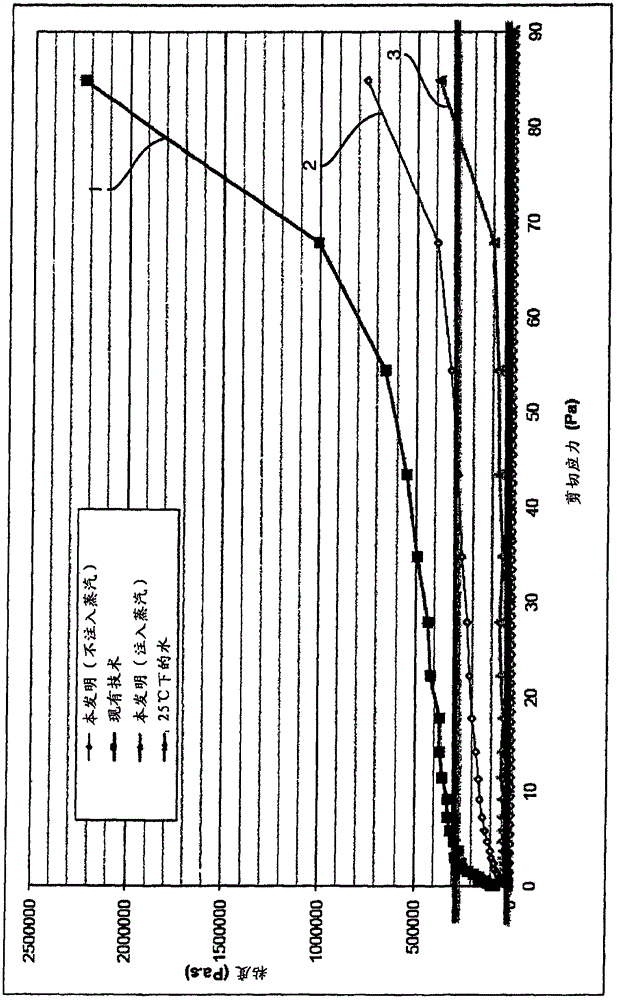

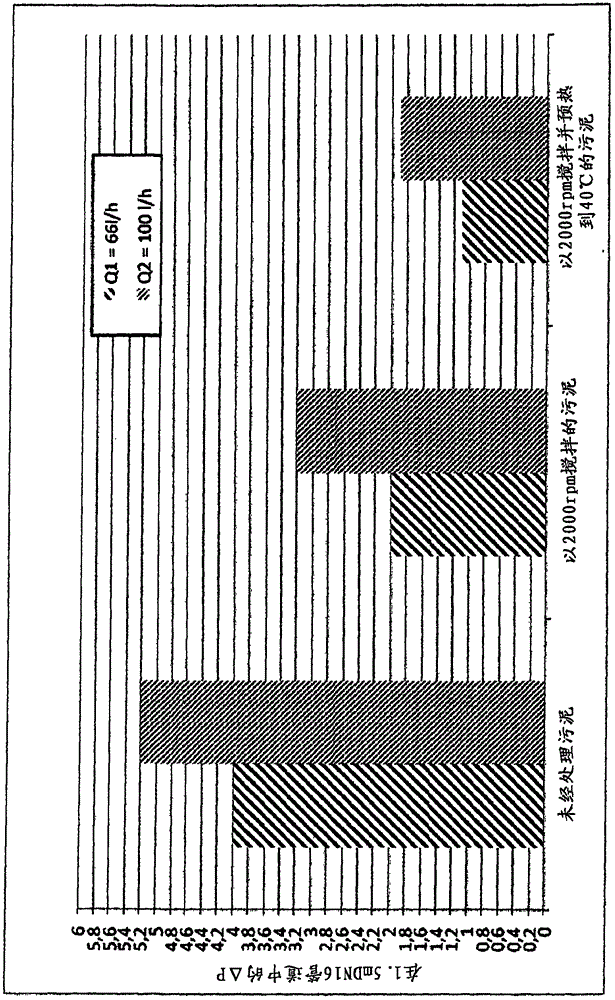

[0073] The general principle of the invention consists in carrying out, upstream of the thermal hydrolysis process, a step of structural disruption of the sludge followed by a step of heating the sludge in a heat exchanger. The step of breaking the structure of the sludge is carried out by subjecting the sludge to a large velocity gradient, enabling its structure to be broken, optionally accompanied by preheating by injection of steam. The thus structurally broken and optionally preheated sludge can enter a heat exchanger where it will be heated by recovering heat from the hydrolyzed sludge. The heating of the preheated or non-preheated structurally disrupted sludge makes it possible to reduce its viscosity, which enables the circulation of the sludge in the heat exchanger while significantly reducing or even completely eliminating the pressure drop within the exchanger. The thus structurally disrupted sludge circulates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotating speed | aaaaa | aaaaa |

| rotating speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com