Rotational transmission device

A technology of rotation transmission device and relative rotation, applied in the direction of non-mechanical drive clutches, one-way clutches, magnetic drive clutches, etc., can solve problems such as troublesome assembly, instability, difficulty, etc., to prevent magnetic leakage, improve attraction force, overlap The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

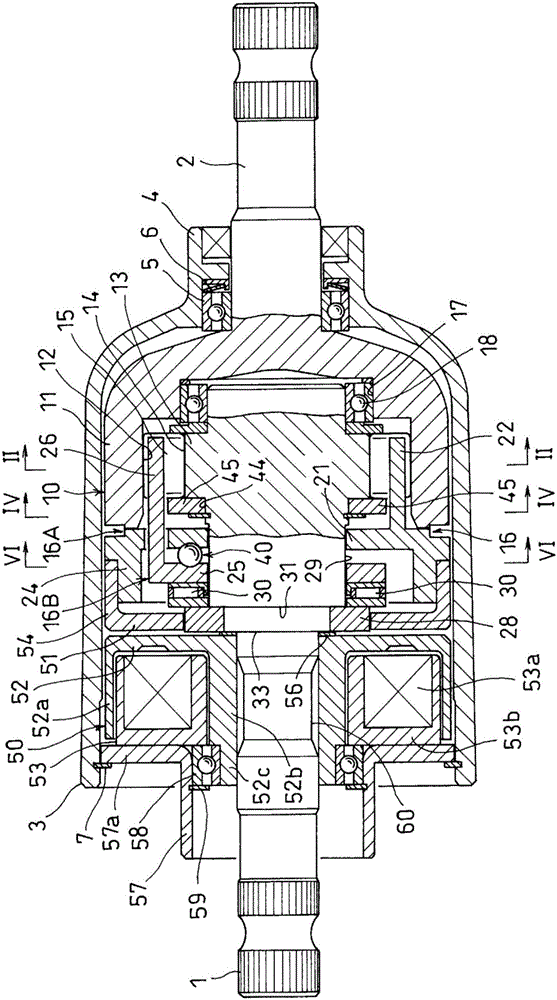

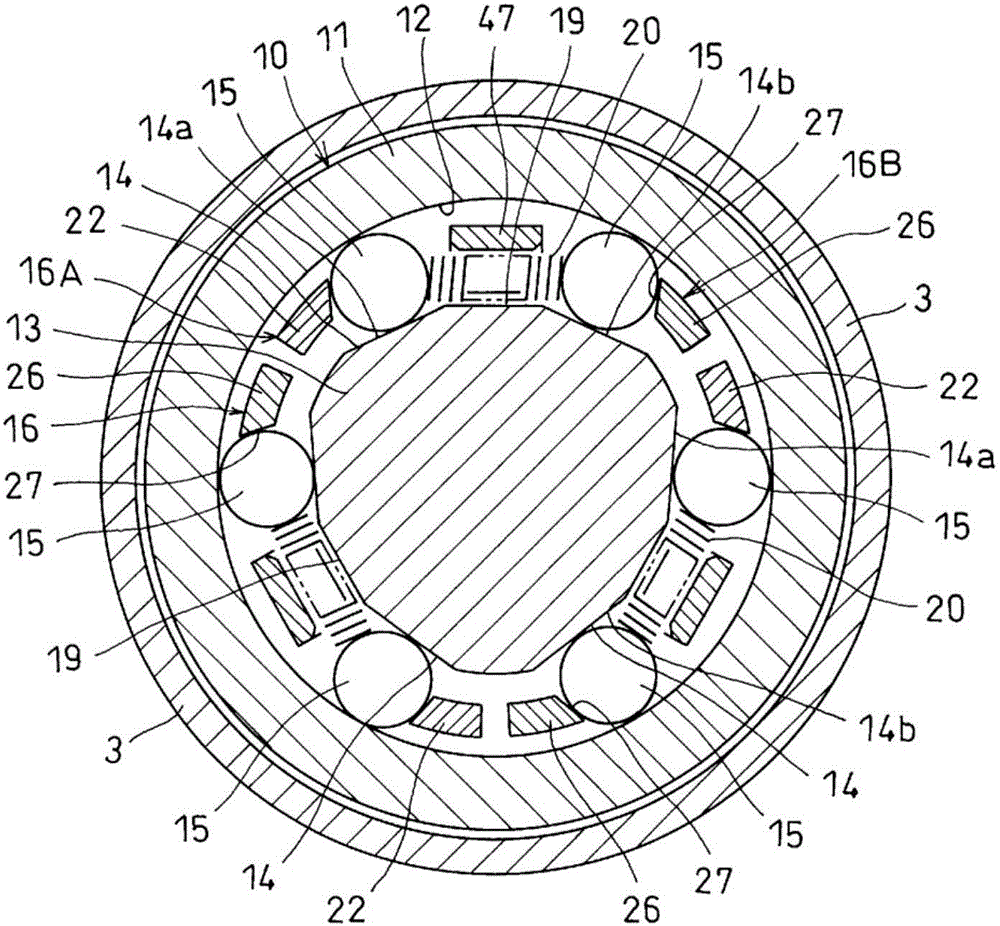

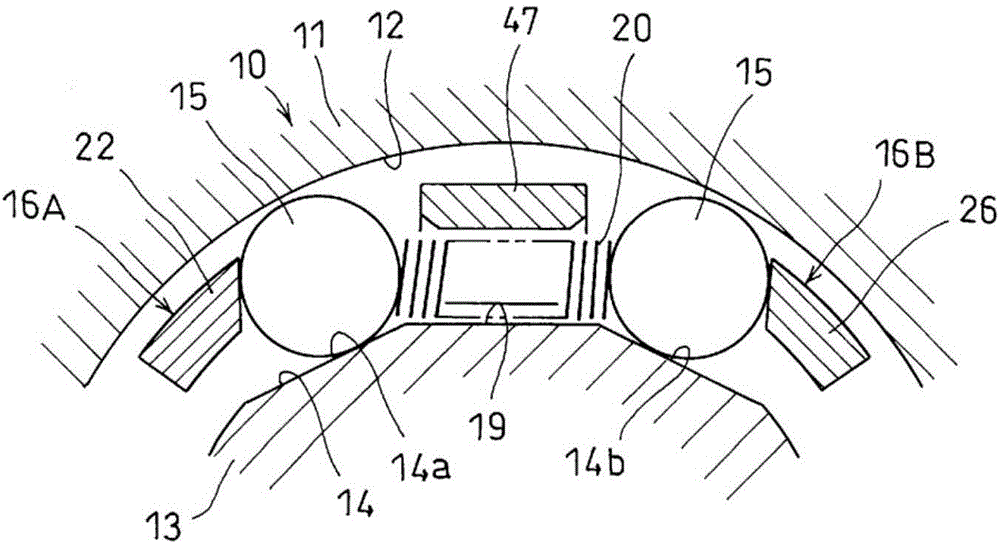

[0033] Embodiments of the present invention will be described below based on the drawings. figure 1 An embodiment of the rotation transmission device according to the present invention is shown. As shown in the figure, the rotation transmission device includes an input shaft 1, an output shaft 2 arranged coaxially with the input shaft 1, a housing 3 covering the shaft ends of the two shafts, which is inserted into the housing 3 and carried out. A two-way clutch 10 that transmits or blocks rotation from the input shaft 1 to the output shaft 2 , and an electromagnetic clutch 50 that controls engagement and release of the two-way clutch 10 .

[0034] The housing 3 is formed in a cylindrical shape, and a small-diameter bearing tube 4 is provided at one end thereof, and the output shaft 2 is rotatably supported by a bearing 5 incorporated in the bearing tube 4 . In addition, an elastic member 6 made of a disc spring is installed in the bearing cylinder 4, and the elastic member 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com