Highly sensitive magnetic sensor and its manufacturing method

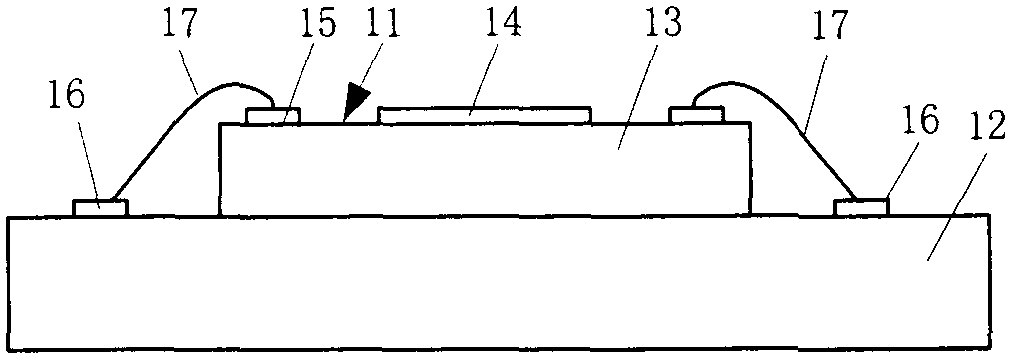

A technology of a magnetic sensor and a manufacturing method, which is applied in the directions of instruments, measuring magnetic variables, and single-equipment manufacturing, can solve the problem of increasing the distance between the magnetic induction film 14 and the measured medium, reducing the sensitivity and consistency of the magnetic sensor, and reducing the yield of the magnetic sensor. and other problems, to achieve the effect of shortening the distance, improving the yield and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the highly sensitive magnetic sensor provided by the present invention will be described in detail below with reference to the accompanying drawings.

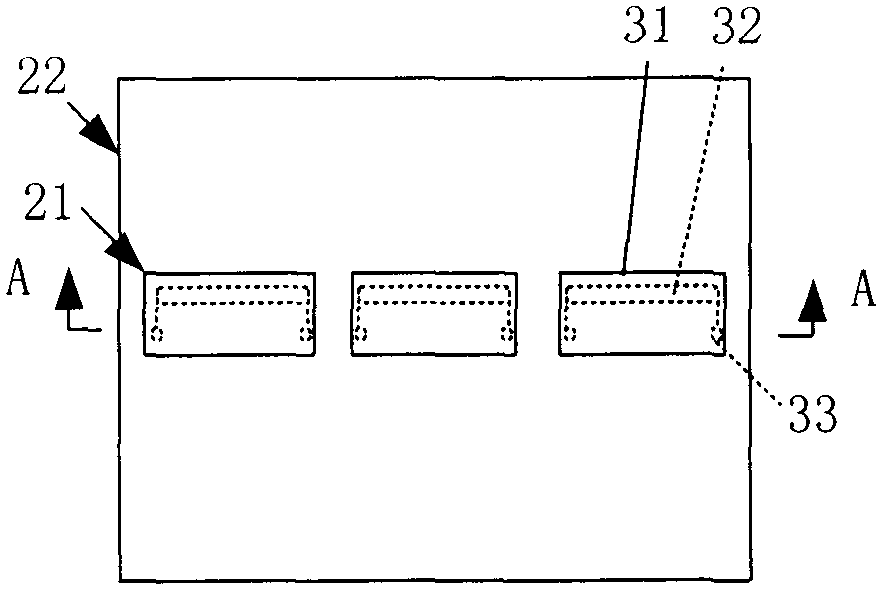

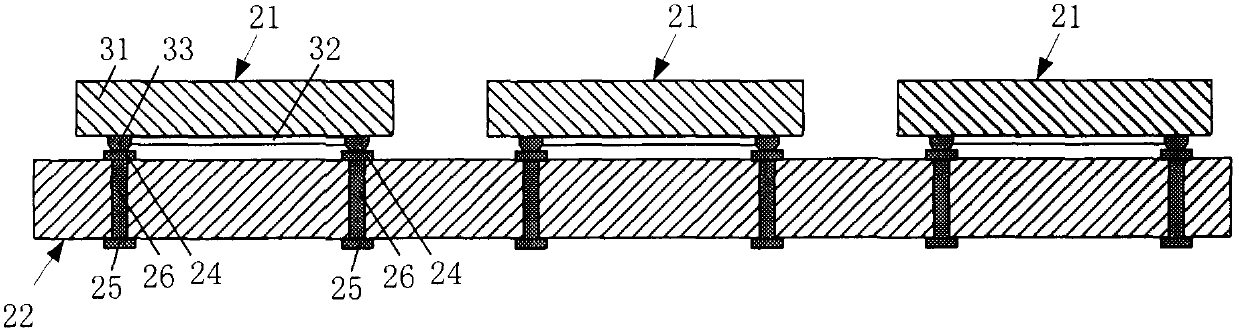

[0038] Such as figure 2 with image 3 As shown, the high-sensitivity magnetic sensor includes a chip 21 and a package substrate 22 , wherein the chip 21 is used to sense a magnetic mark disposed in the detected medium and output an induction signal. The packaging substrate 22 is used to support and fix the chip 21 and at the same time lead out the induction signal of the chip 21 . The magnetic sensor can be provided with one chip 21 or multiple chips 21 as required. When the magnetic sensor includes multiple chips 21 , the multiple chips 21 are arranged in a horizontal arrangement so as to completely cover the width direction of the magnetic sensor. In this embodiment, a magnetic sensor provided with thre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap