Rapid-replacement high-precision gang cutter and machining method thereof

A technology that combines milling cutters and processing methods, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of unreasonable utilization of tool resources, inadequate coordination of tool heads and tool holders, and reduced processing efficiency of workpieces. The effect of reducing re-calibration steps, improving tool carrying capacity, and improving tool change efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

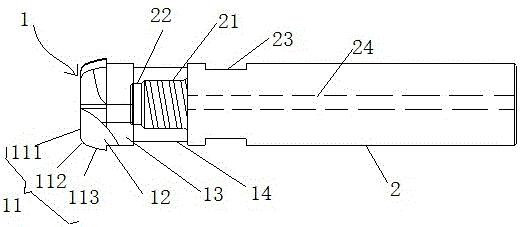

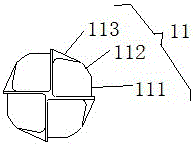

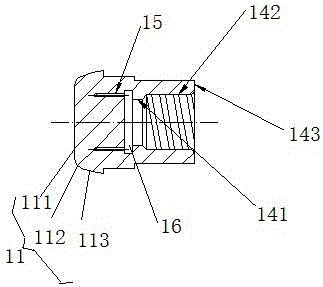

[0033] Such as Figure 1-5 A quick-change high-precision combined milling cutter and its processing method are shown, including a cutter head 1 and a handle 2, characterized in that: the cutter head 1 is a cutting edge 11 from the end to the tail, and the chip removal groove 12. The space-avoiding part 13, the high-speed steel substrate 14, the number of the cutting edges 111 is 4 and they are symmetrically arranged at the end of the cutter head 1. The chip removal groove 12 is located between the two cutting edges 11. The cutting The edge 11 includes a cutting edge I111, a cutting edge II112, and a cutting edge III113. The cutting edge II112 is arranged between the cutting edge I111 and the cutting edge III113. and the high-speed steel substrate 14 are fixed by high-temperature welding. The high-speed steel substrate 14 is provided with an axial positioning hole 141, a threaded hole 142 and a radial positioning surface 143. The axial positioning hole 141 is arranged at the fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com