Vertical type production line for rubber refiner

A refining machine and production line technology, applied in the fields of reclaimed rubber powder refining equipment and rubber production machinery and equipment, can solve the problem of too many conveying equipment, and achieve the effect of reducing conveying equipment, saving manpower and material resources, and ensuring performance parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

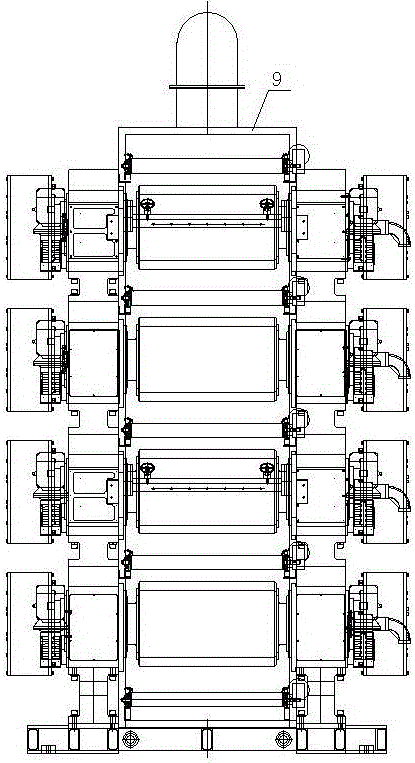

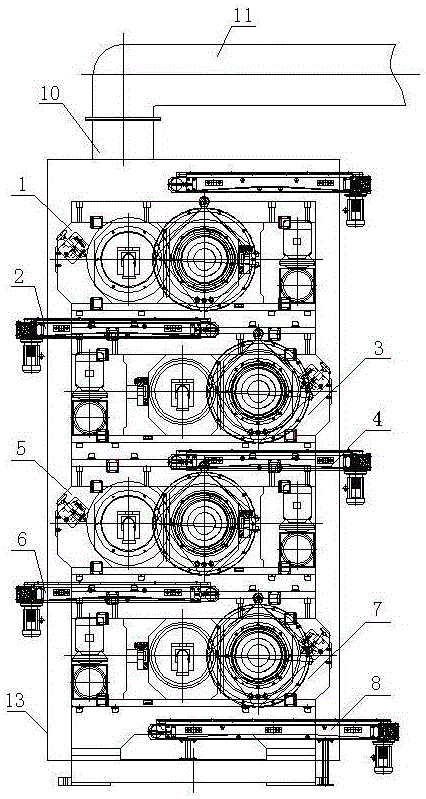

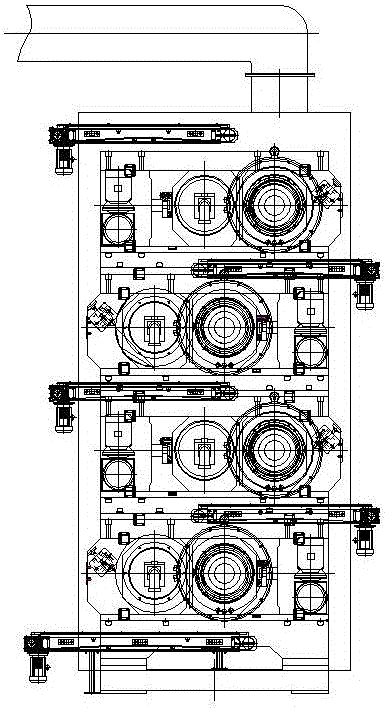

[0014] Rubber refiner vertical production line structure of the present invention is as Figure 1-4 As shown in the figure, the installation method of the vertical rubber refining machine production line is changed to vertical installation. Each refining machine is placed on the cover plate of the equipment below, and is positioned with positioning keys to reduce the vibration of the equipment and increase the safety of the equipment. The third refiner 5 is arranged on the upper cover of the fourth refiner 7, the second refiner 3 is arranged on the upper cover of the third refiner 5, and the first refiner 1 is arranged on the upper cover of the second refiner 3 , the first conveyor belt 2, the second conveyor belt 4, the third conveyor belt 6 are respectively provided with the first conveyor belt 2, the second conveyor belt 4, and the third conveyor belt 6 below the sheet-discharging rollers of the first refiner 1, the second refiner 3, the third refiner 5 and the fourth refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com