Method for fabricuting single piece of fire-resisting glass

A technology of fireproof glass and manufacturing method, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of uneven heat source, affect the performance index of fireproof glass, uneven cooling, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

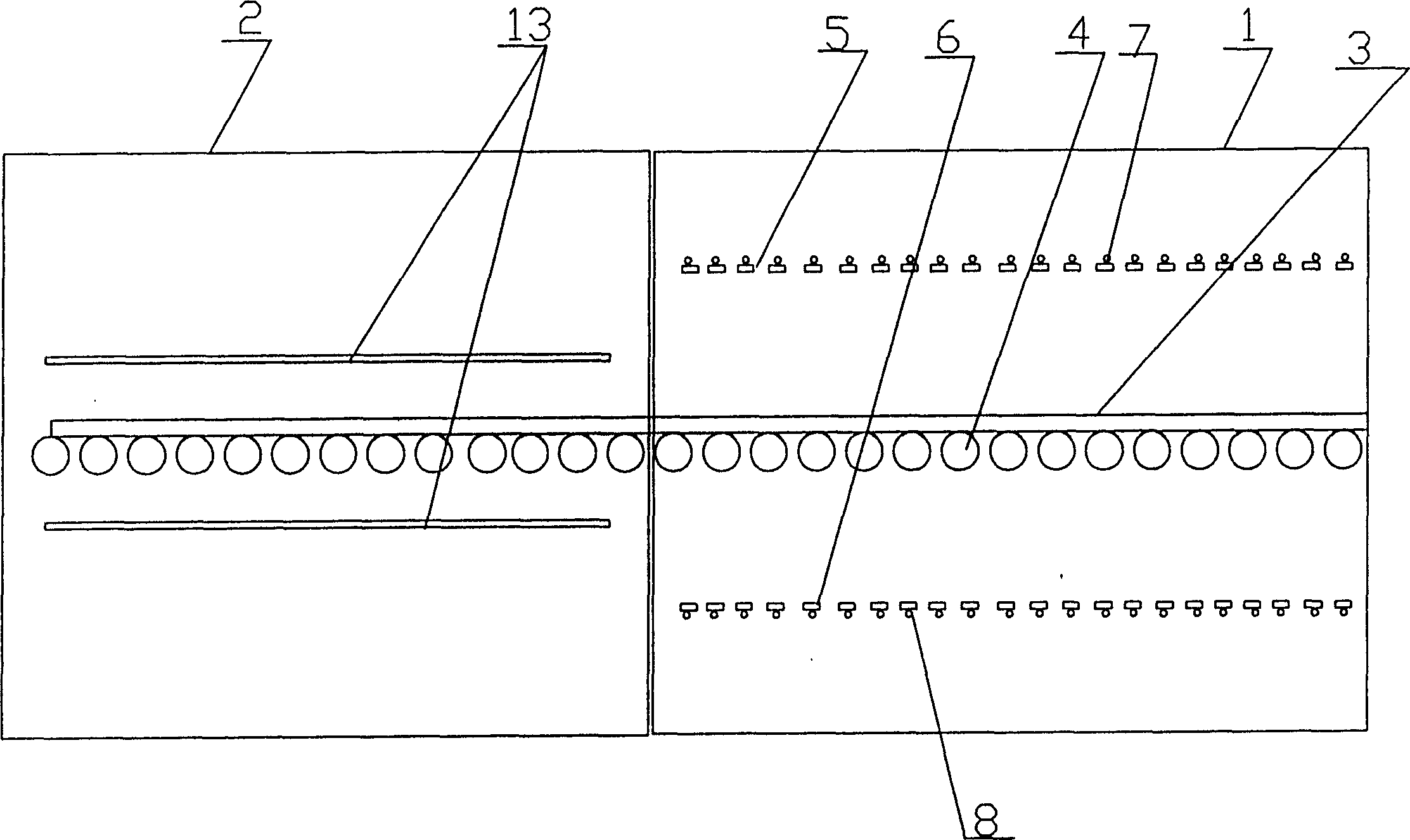

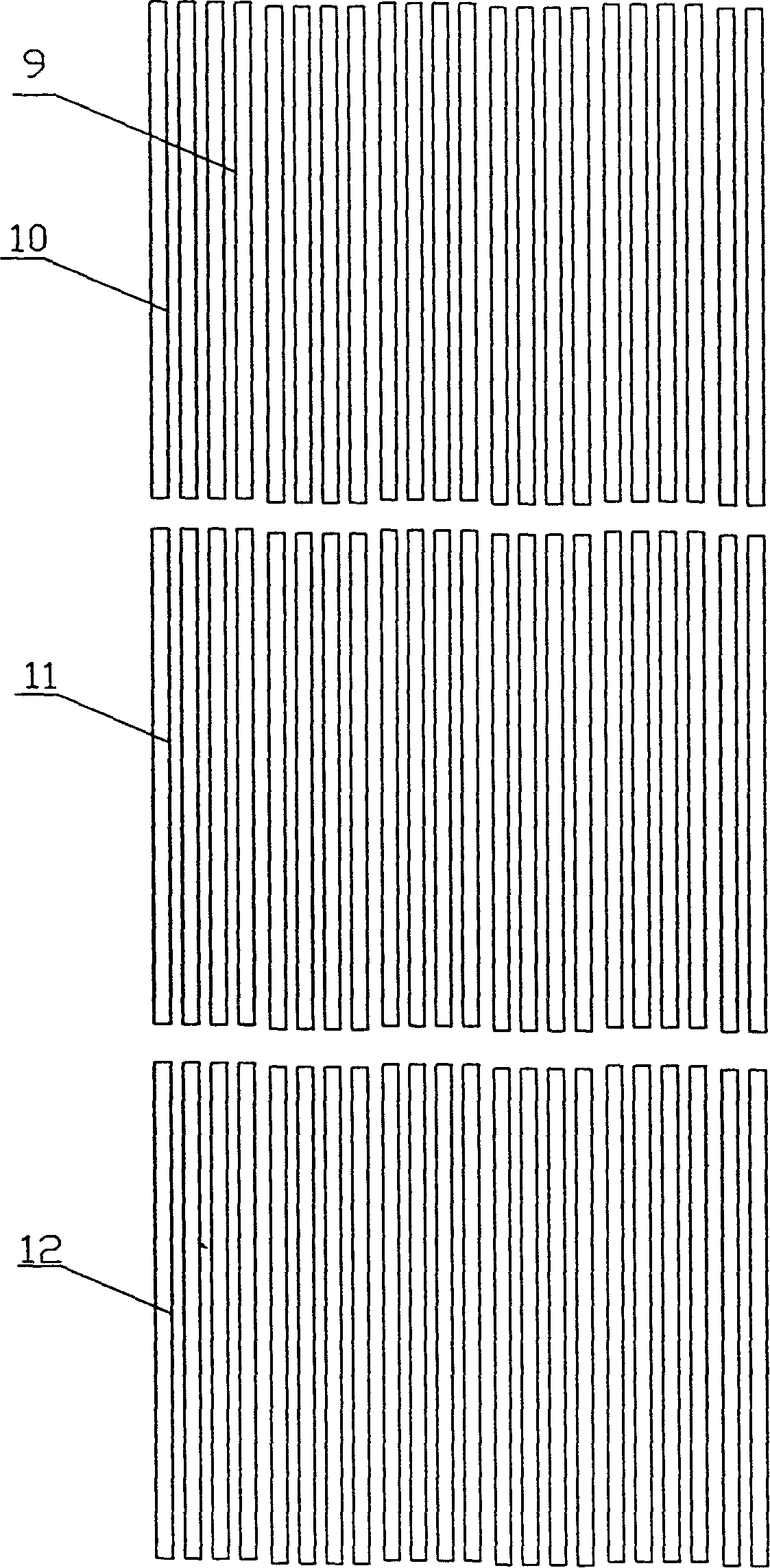

[0023] Such as Figure 1 to Figure 2 As shown, a method of manufacturing a single piece of fireproof glass, the original piece of glass is selected for polishing, cleaned and dried, then heated in a high-temperature heating furnace 1, and finally cooled out of the furnace through a high-pressure air-cooling chamber 2, and the glass 3 is heated in a high-temperature heating furnace. 1 is driven by the roller 4 to perform reciprocating circular motion, so that the glass 3 is evenly heated. The high-temperature heating furnace 1 has two layers of heat radiation plates 5 and 6 evenly distributed on the upper and lower sides of the furnace body. The upper and lower ends of the upper heat radiation plate 5 are heated Electric heating bodies 7 and 8 are arranged under the radiating plate 6, and the heat radiating plate of each layer is formed by a plurality of small radiating plates 9 evenly distributed and arranged, and the heat radiating plates of the upper and lower layers are in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com