Plastic extruders for the production of biodegradable mulches

A technology for degrading mulch and plastics, applied in the field of plastic extruders, can solve the problems of narrow temperature deviation range, material is not easy to melt, long heating time, etc., to achieve the effect of small deviation range, increased range and range of movement, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

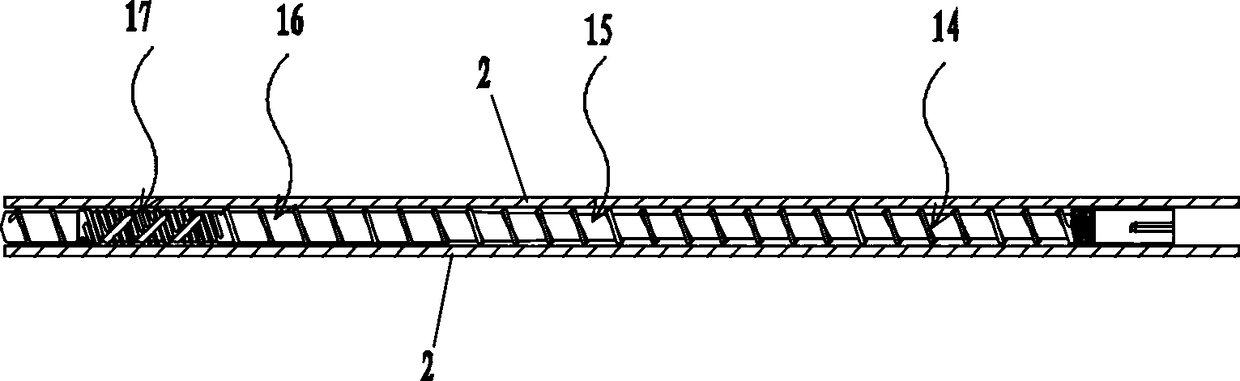

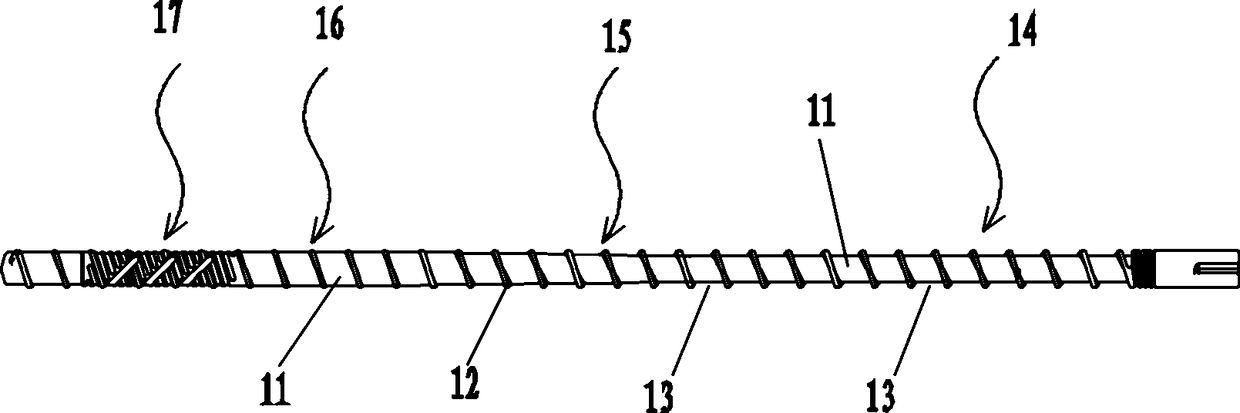

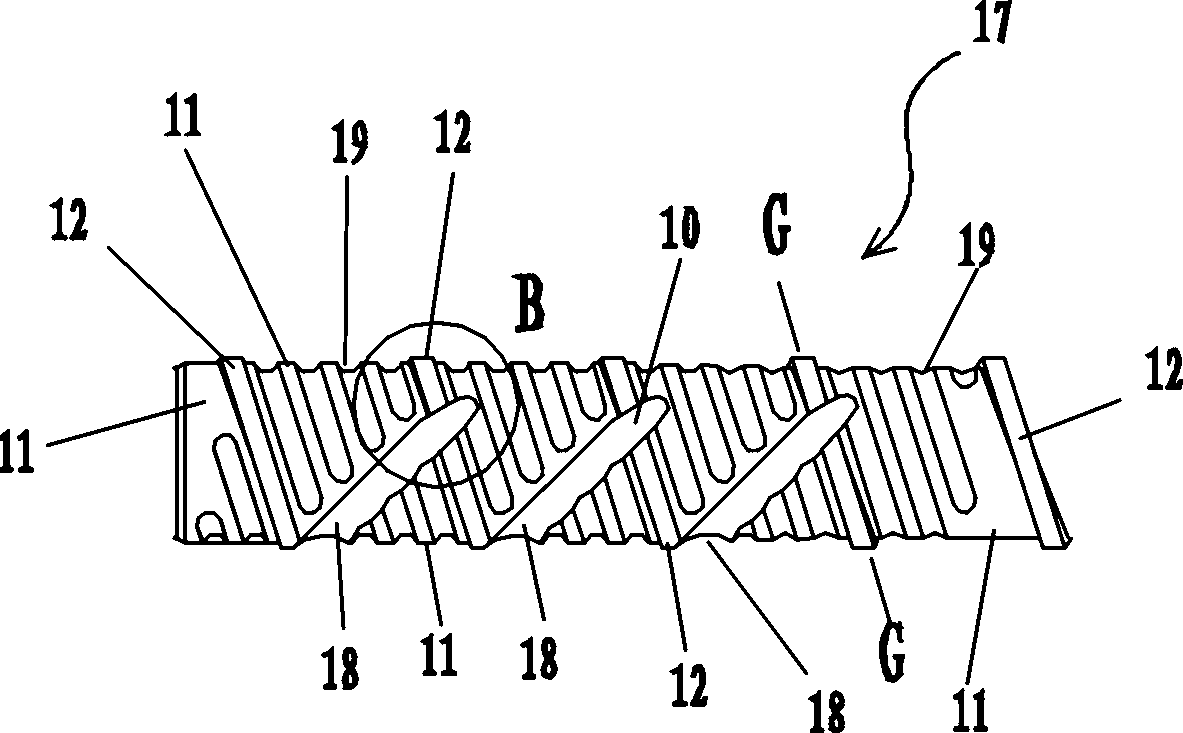

[0024] The plastic extruder used to produce degradable mulch film of this embodiment comprises barrel 2 and screw rod, figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the screw rod includes a strip-shaped circular rod body 11, a helically extended flight 12, and the screw flight 12 protrudes outwards relative to the circumferential surface of the circular rod body, and the sides of the screw flight 12 (such as Figure 7 The side shown by the midline segment mn) is close to the inner surface of the barrel 2, and an annular gap is formed between the surface of the circular rod body 11 and the inner surface of the barrel 2, and the annular gap is separated by a screw edge to form a screw groove 13 The screw rod is divided into feeding section 14, compression section 15, homogenization section 16, and barrier section 17 from back to front, wherein the screw groove depth of feeding section 14 remains constant, and the screw groove depth of compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com