A bubble elimination process for automobile laminated glass

A technology for laminated glass and bubble elimination, applied in lamination, lamination devices, layered products, etc., can solve the problems of local dense bubbles that are difficult to eliminate at one time, low operability and repairing efficiency, and sharp end bends. To achieve the effect of strong core competitiveness, good market potential and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of automobile laminated glass air bubble elimination process of the present invention comprises the following steps:

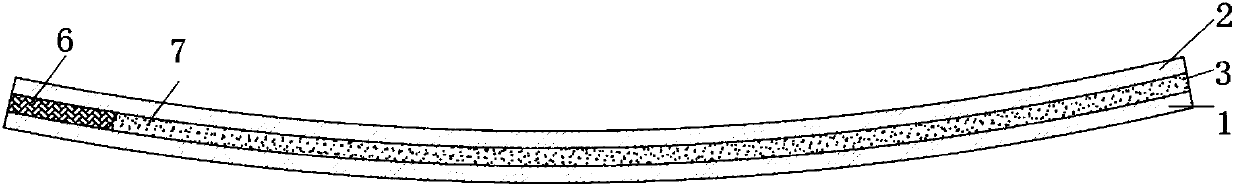

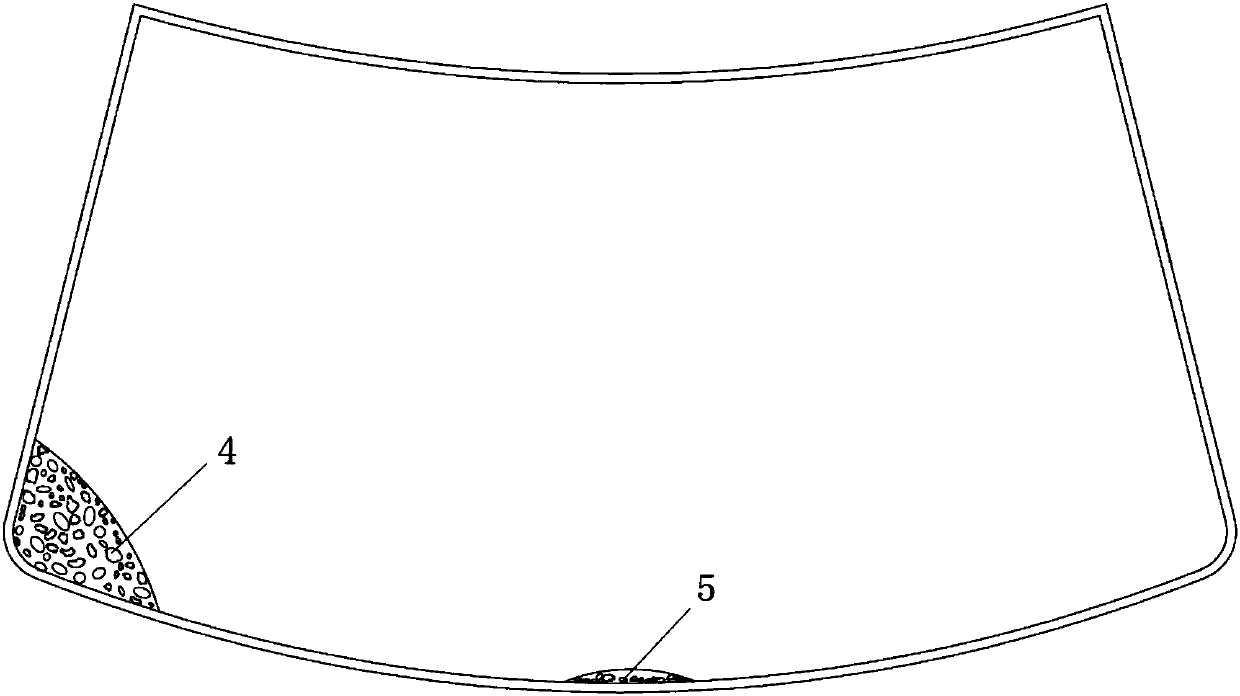

[0031] (1) First prepare the special tools and auxiliary materials for repairing and eliminating air bubbles: 1. Light holders for placing multi-curvature automotive glass; Partial heating of the glass, light and flexible; 3. Customized special-shaped stainless steel brazing, with a thickness of 0.5mm, one end is semicircular, used to squeeze the filler, and the other end is tapered, used to stab even dense air bubbles Bubbles in Zone 4; 4. Used for injecting plastic injection syringes; 5. PVB edge material, used as filler in crack 6; 6. Liquid injection molding agent used for high-pressure post-sealing.

[0032] (2) Implementation steps: 1. Place the glass on the light stand, power on the self-air temperature-adjusting plastic welding torch, and the hot air at the air outlet will quickly heat up to about 150°C, and then direct the air outlet ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com