Microbial method for remedying aromatic hydrocarbon-heavy metal ion complex pollution

A heavy metal ion and complex pollution technology, applied in the field of microbiology and environmental science, can solve the problems of high energy consumption, unsuitable for large areas, complicated operation, etc., achieve stable mineral properties, significant repair effect, and slow down the greenhouse effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

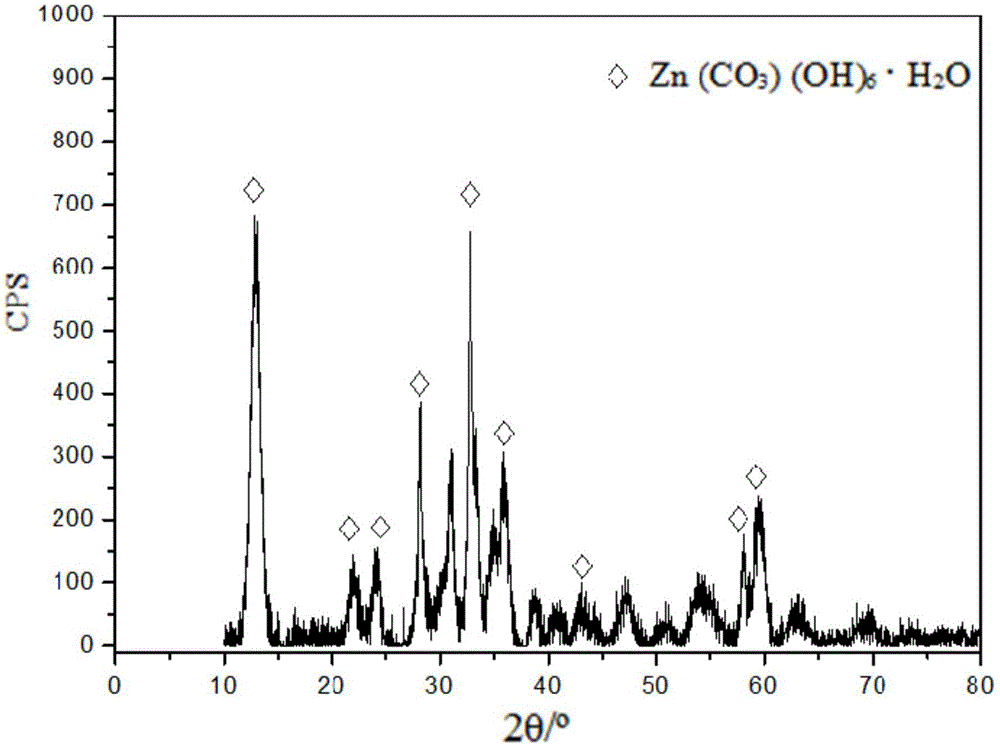

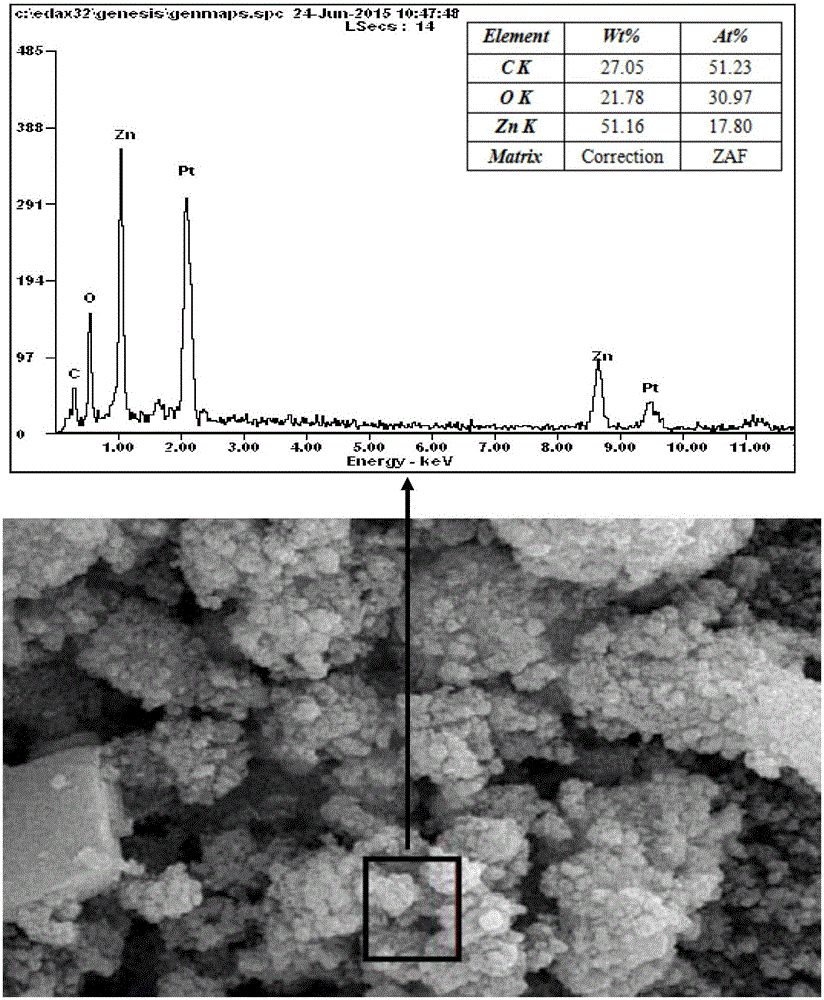

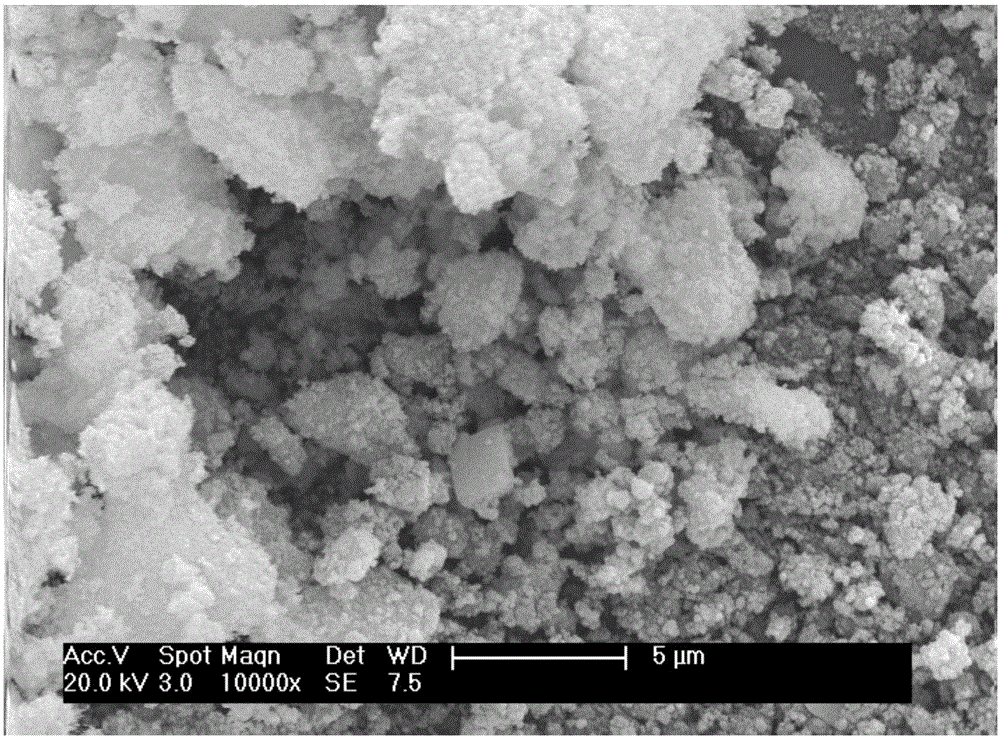

Image

Examples

example

[0036] (1) Weigh 5g of peptone, 3g of beef extract, 5g of NaCl, 15g of agar, MgSO 4 Dissolve 0.4g in 1000ml of deionized water, and control the pH to 7, sterilize at 125°C for 30 minutes, take it out and wait for cooling; inoculate Pseudomonas putida into the cooling medium solution, shake culture at 30°C, shake The frequency is 170r / min, and the culture time is 24h; centrifuge the cultivated bacterial liquid at high speed for 10min, the speed of the centrifuge is 8000rpm, and the temperature is 4°C. Remove the nutrients in the upper medium, and add 100mL of deionized water to make a concentrated bacterial liquid.

[0037] (2) Weigh 18g of agar and dissolve it in 1000ml of wort at 5°C, sterilize at 125°C for 30 minutes, take it out and wait for cooling; inoculate the yeast into the cooling medium solution, and culture at 30°C with shaking at a frequency of 170r / min, culture time 24h; Centrifuge the cultured bacterial solution at high speed for 10min, the speed of the centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com