Universal adjusting type independent wheel hanging mechanism for trailer

An independent suspension and universal adjustment technology, which is applied to trailers, suspensions, motor vehicles, etc., can solve the problems that the independent suspension mechanism cannot be adjusted universally and is inconvenient to use, and achieves good shock absorption and reliability. Easy to use, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

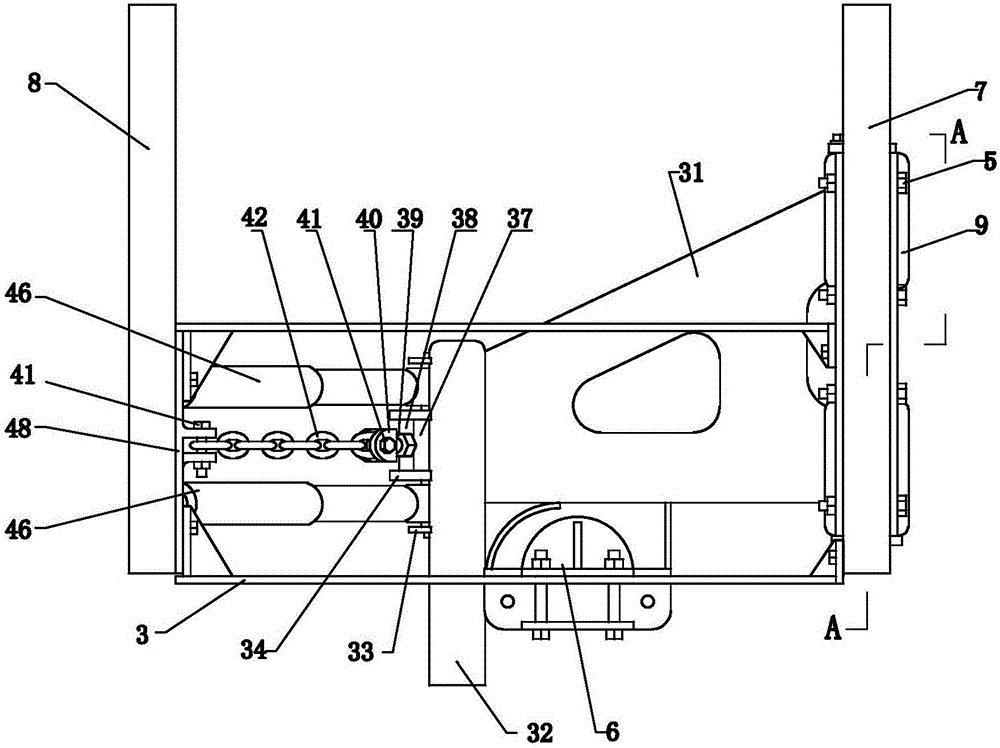

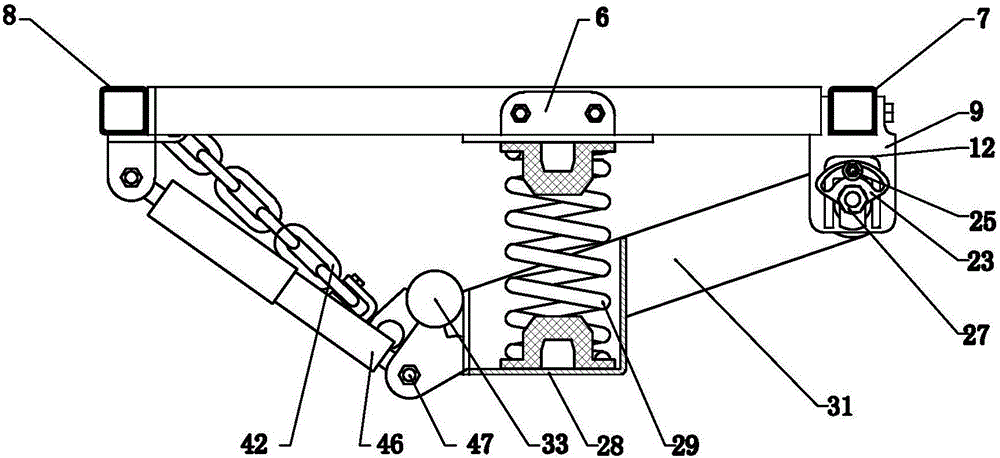

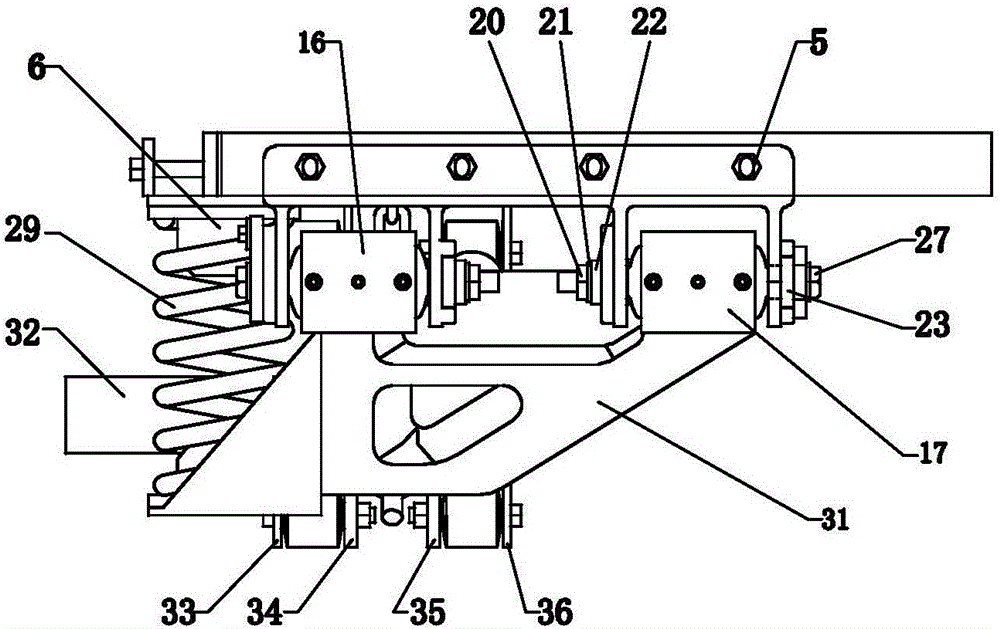

[0023] as attached Figure 1-10 In the shown embodiment, the present invention is provided with: wheel independent suspension frame, wheel shaft 32, front bracket 9, main swing arm 31, rear bracket 48, height adjustment chain 42, outer spherical eccentric adjustment assembly 16, inner spherical eccentric Adjustment assembly 17, damping shock absorber 46, wheel independent suspension frame is composed of front beam 7 and rear beam 8 which are welded in parallel by two relative frames 3, and bolt 5 at the bottom of front beam 7 The front bracket 9 is connected with the front bracket 9, and the outer spherical eccentric adjustment assembly 16 and the inner spherical eccentric adjustment assembly 17 are installed respectively on the front bracket 9. The wheel shaft 32 is welded on the tail end of the main swing arm 31, and the main swing arm 31 It is composed of the main swing arm upper plate and the main swing arm lower plate welded together to form the main swing arm with the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com