Automatic dishing machine of cake foods

A technology of tray loading machine and food, which is applied in the fields of baked food processing, packaging, food science, etc., and can solve the problems of low work efficiency, food deformation and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

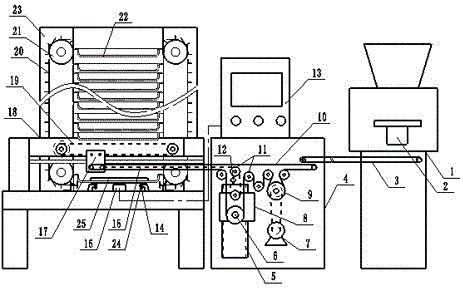

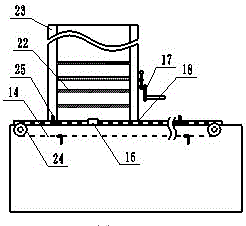

[0010] Examples such as figure 1 and figure 2 Shown: an automatic food loading machine, the loading machine is composed of a food forming machine 1, a first conveyor belt 3, a second conveyor belt 10, a controller 14 and a plate unloading machine 18, at the outlet of the food forming machine 1 2 The first conveyor belt 3 is installed horizontally below, and the end of the first conveyor belt 1 is installed above the head end of the second conveyor belt 10; the end of the second conveyor belt 10 is installed on the moving block 17, and the moving block 17 is installed in the cabinet. On the chain 19, the lower segment of the second conveyor belt 10 is installed in the adjusting device 4, and the adjusting device 4 is equipped with a guide roller 11, a power roller 9 and a lifting plate 8, and the lifting plate 8 is installed on the vertical guide rail 5, and the lifting plate 5, a fixed rod 12 is installed on the moving block 17, and a gravity pull-back belt 15 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com