Adaptive start-stop method for forward and reverse coal flow in mine transportation system

A transportation system, startup and shutdown technology, applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems of waste of belt transportation resources, long running time of belt conveyors, and slow technical improvement, etc., so as to facilitate popularization and use , Easy to promote, novel and reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

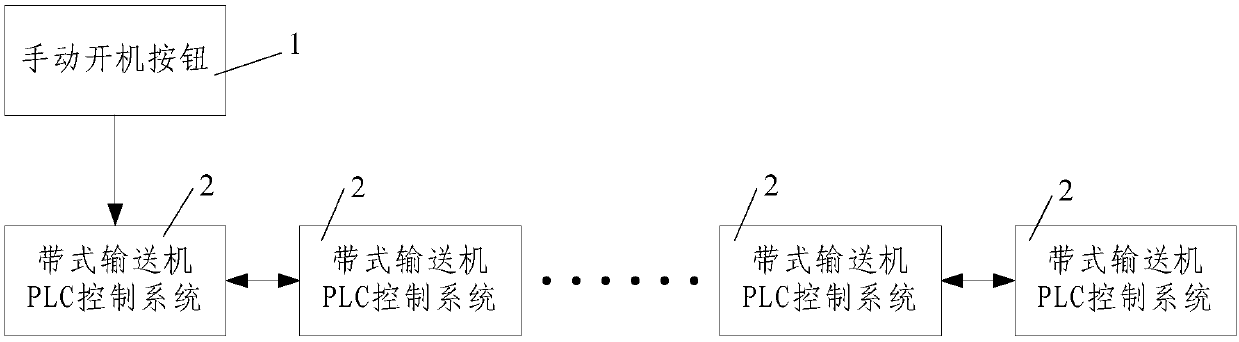

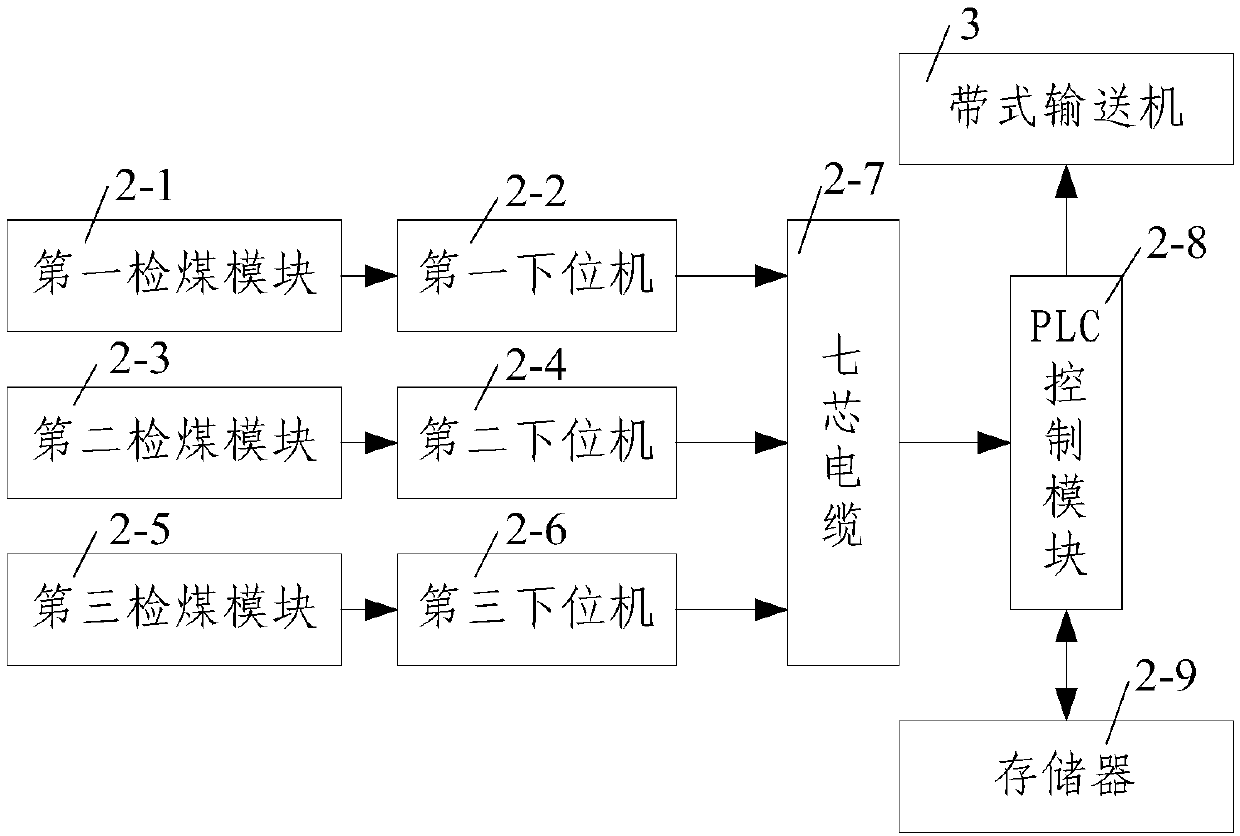

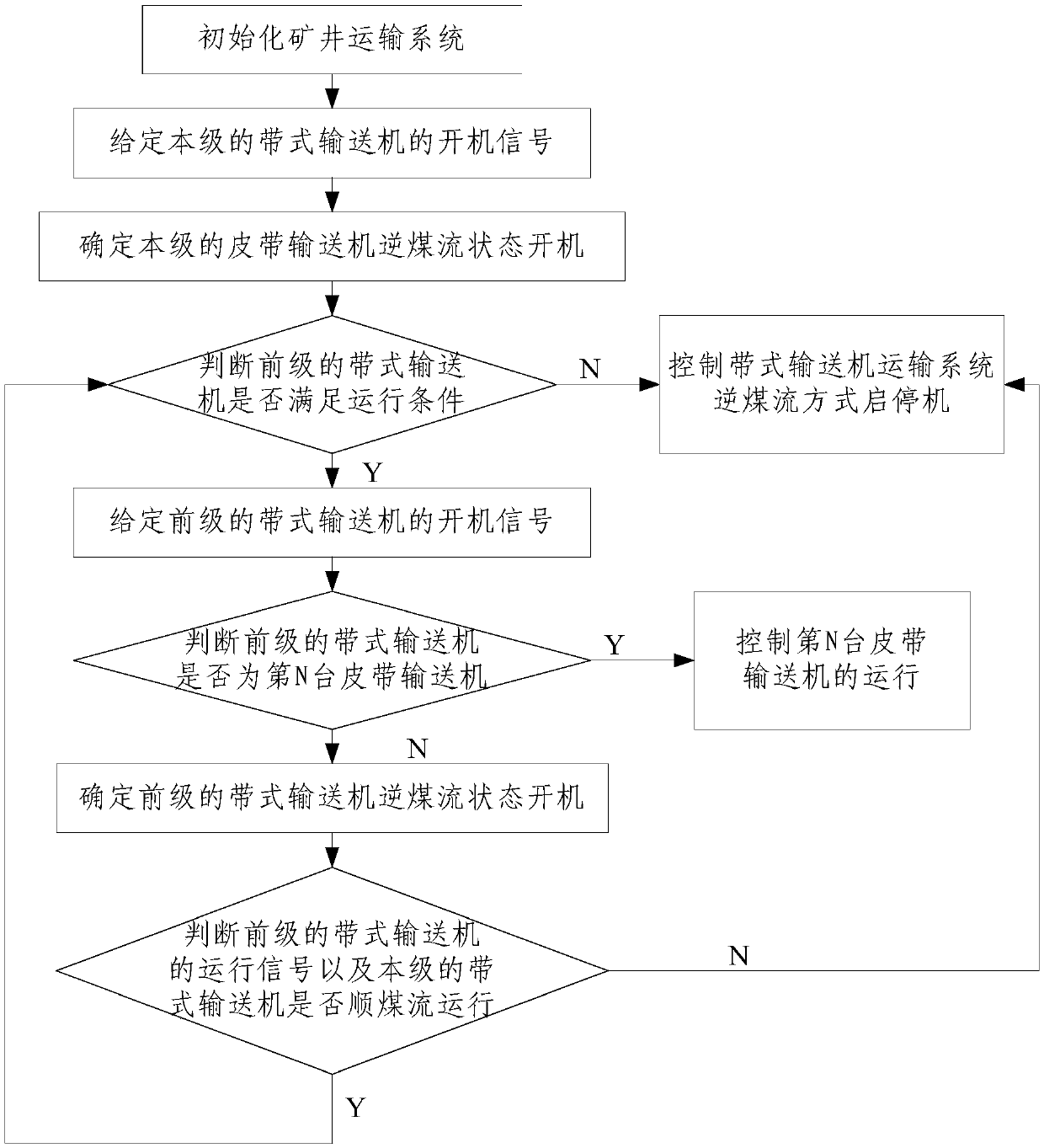

[0042] Such as figure 1 , figure 2 and image 3 As shown, the self-adaptive startup and shutdown method of the mine transportation system in the forward and reverse direction of the coal flow of the present invention comprises the following steps:

[0043] Step 1. Initialize the mine transportation system: reset the N sequentially connected belt conveyor PLC control systems 2 arranged in the underground by means of power-on reset. Between two adjacent belt conveyor PLC control systems 2 Chain protection, where N is a positive integer and N≥2;

[0044] N sequentially connected belt conveyor PLC control systems 2 are respectively used to control the start and stop of N belt conveyors 3 adjacent to each other, and N belt conveyor PLC control systems 2 and N belt conveyors 3 in one-to-one correspondence, N sets of belt conveyors 3 adjacent to each other are laid out along the underground roadway from the coal seam working face of the back stage to the ground of the front stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com