Reinforcing rib for long-service-life wire-drawing bushing for producing continuous basalt fibers and bushing

A basalt fiber, wire drawing bushing technology, applied in glass manufacturing equipment, manufacturing tools and other directions, can solve the problem of the deformation effect of the bottom plate and other problems, and achieve the effect of improving the service life, reducing the high temperature creep performance and strong supporting force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

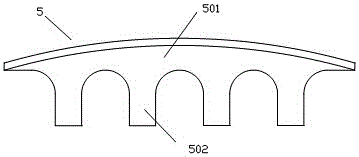

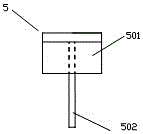

[0023] Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a reinforcing rib for producing continuous basalt fiber high-life drawing bushings, the reinforcing rib 5 is arched, and the reinforcing rib 5 includes a rib column 502 and an upwardly protruding arc rib On the surface 501, the rib column 502 is welded on the lower surface of the rib surface 501; an arch hole is formed between two adjacent rib columns 502.

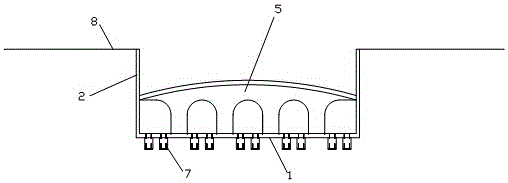

[0024] The reinforcing rib of the above structure can improve the service life of the wire drawing bushing for producing continuous basalt fiber. When in use, the reinforcing rib 5 is located in the cavity of the drawing bushing, and the reinforcing rib 5 is fixedly connected to the side wall plate 2 and the base plate 1 of the drawing bushing. As the basalt melt is a black melt, the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com