A kind of high-density polyethylene toughening masterbatch and its preparation method and its application in high-density polyethylene pipe

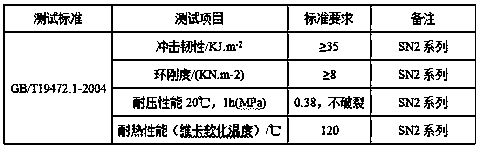

A high-density polyethylene and toughening masterbatch technology, applied in high-density polyethylene pipes, high-density polyethylene toughening masterbatch and its preparation field, can solve the low impact toughness and ring stiffness of HDPE municipal pipes , easy to be brittle, easy to deform and other problems, to achieve the effect of improving impact toughness and ring stiffness, improving compatibility, improving impact toughness and ring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

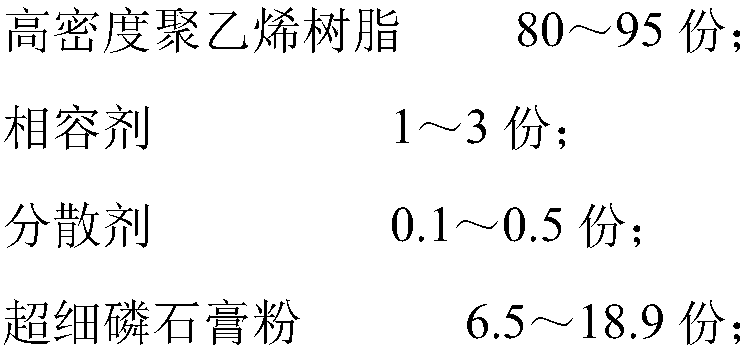

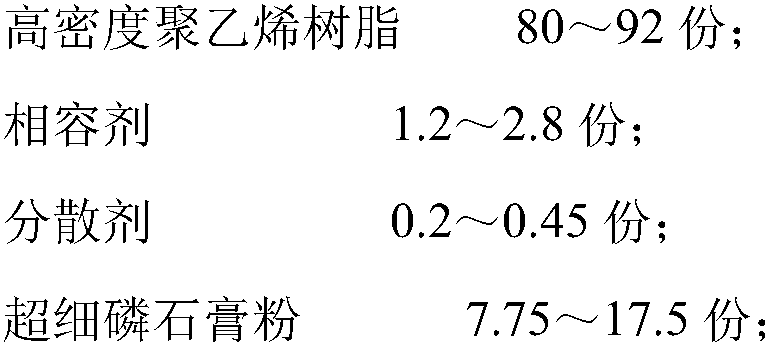

[0041] Example 1 A kind of high-density polyethylene toughened masterbatch 1

[0042] Step 1: Selection of raw materials: 80 parts by weight of HDPE resin, 18.9 parts of ultrafine phosphogypsum powder (1200 mesh); 1 part of compatibilizer (PP-g-MAH), dispersant carboxyl-terminated liquid nitrile rubber 0.1 Copies.

[0043] Step 2: Reactive extrusion: The extrusion process is: 180°C in the first zone, 185°C in the second zone, 190°C in the third zone, 195°C in the fourth zone, 200°C in the fifth zone, 200°C in the head; the screw speed is 200 r / min, Configure HDPE blend containing compatibilizer (PP-g-MAH), dispersant (CTBN) and ultra-fine phosphogypsum powder and add it to the twin-screw extruder for reactive extrusion molding, cooling, and pelletizing. Sexual material A;

[0044] Step 3: Drying: The modified material A obtained in step 2 is dried in an oven at a temperature of 90° C. for 240 minutes, and the modified material B obtained is a high-density polyethylene toughened mas...

Embodiment 2

[0045] Example 2 A kind of high density polyethylene toughened masterbatch 2

[0046] Step 1: Selection of raw materials: 85 parts by weight of HDPE resin, 15.4 parts of ultrafine phosphogypsum powder (600 mesh); 1.5 parts of compatibilizer (PP-g-MAH), dispersant carboxyl-terminated liquid nitrile rubber 0.1 Copies.

[0047] Step 2: Reactive extrusion: The extrusion process is: 180°C in the first zone, 185°C in the second zone, 190°C in the third zone, 195°C in the fourth zone, 200°C in the fifth zone, 200°C in the head; the screw speed is 200 r / min, Configure the HDPE blend containing the compatibilizer (PP-g-MAH), dispersant ((CTBN) and ultrafine phosphogypsum powder into the twin-screw extruder for reactive extrusion molding, cooling, and pelletizing to obtain Modified material A;

[0048] Step 3: Drying: The modified material A obtained in step 2 is dried in an oven at a temperature of 90° C. for 240 minutes, and the modified material B obtained is a high-density polyethylene t...

Embodiment 3

[0049] Example 3 A kind of high-density polyethylene toughened masterbatch 3

[0050] Step 1: Selection of raw materials: 90 parts by weight of HDPE resin, 7.8 parts of ultrafine phosphogypsum powder (2000 mesh); 2 parts of compatibilizer (PP-g-MAH), dispersant carboxyl-terminated liquid nitrile rubber 0.1 Copies.

[0051] Step 2: Reactive extrusion: The extrusion process is: 180°C in the first zone, 185°C in the second zone, 190°C in the third zone, 195°C in the fourth zone, 200°C in the fifth zone, 200°C in the head; the screw speed is 200 r / min, Configure the HDPE blend containing the compatibilizer (PP-g-MAH), dispersant ((CTBN) and ultrafine phosphogypsum powder into the twin-screw extruder for reactive extrusion molding, cooling, and pelletizing to obtain Modified material A;

[0052] Step 3: Drying: The modified material A obtained in step 2 is dried in an oven at a temperature of 90° C. for 240 minutes, and the modified material B obtained is a high-density polyethylene tou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com