Polyether-ether-ketone wire enamel and preparation method thereof

A technology of polyetheretherketone and enameled wire paint, applied in the field of enameled wire paint, can solve the problem that the heat-resistant coating cannot meet the demand, etc., and achieve the effects of excellent high temperature resistance, uniform paint film and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

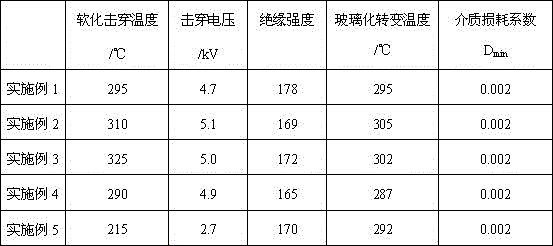

Examples

Embodiment 1

[0019] A polyetheretherketone wire enamelled varnish, raw materials include by weight: 3 parts of 4,4'-difluorobenzophenone, 1 part of hexafluorobisphenol A, 4 parts of hydroquinone, 1 part of potassium carbonate, 2 parts of sulfolane, 3 parts of styrene, 1 part of hydroxypropyl acrylate, 2 parts of epoxy resin, 3 parts of tributyl phosphate, 2 parts of ethylene glycol ether, 1 part of ethylene-vinyl acetate copolymer, dimethylformamide 3 parts, 1 part of silica sol, 3 parts of adipic acid, 2 parts of neopentyl glycol, 1 part of sodium pyrophosphate, 3 parts of oleic acid, 6 parts of polyethylene glycol 200, 1 part of lecithin, 3 parts of citric acid, Magnesium borate 2 parts.

[0020] The preparation method of the polyether ether ketone wire enamel, comprises the following steps:

[0021] Step 1, mix 4,4'-difluorobenzophenone, hexafluorobisphenol A, hydroquinone, potassium carbonate and sulfolane, react at 120°C for 4 hours, add dropwise a mixture of styrene and hydroxypropy...

Embodiment 2

[0026] A polyetheretherketone wire enamelled varnish, raw materials include by weight: 5 parts of 4,4'-difluorobenzophenone, 2 parts of hexafluorobisphenol A, 7 parts of hydroquinone, 3 parts of potassium carbonate, 5 parts of sulfolane, 4 parts of styrene, 2 parts of hydroxypropyl acrylate, 5 parts of epoxy resin, 4 parts of tributyl phosphate, 6 parts of ethylene glycol ethyl ether, 3 parts of ethylene-vinyl acetate copolymer, dimethylformamide 5 parts, 4 parts of silica sol, 6 parts of adipic acid, 3 parts of neopentyl glycol, 2 parts of sodium pyrophosphate, 7 parts of oleic acid, 9 parts of polyethylene glycol 300, 3 parts of lecithin, 5 parts of citric acid, Magnesium borate 4 parts.

[0027] The preparation method of the polyether ether ketone wire enamel, comprises the following steps:

[0028] Step 1, mix 4,4'-difluorobenzophenone, hexafluorobisphenol A, hydroquinone, potassium carbonate and sulfolane, react at 140°C for 3 hours, add dropwise a mixture of styrene and...

Embodiment 3

[0033] A polyetheretherketone wire enamelled varnish, raw materials include by weight: 7 parts of 4,4'-difluorobenzophenone, 2 parts of hexafluorobisphenol A, 6 parts of hydroquinone, 3 parts of potassium carbonate, 5 parts of sulfolane, 5 parts of styrene, 2 parts of hydroxypropyl acrylate, 3 parts of epoxy resin, 4 parts of tributyl phosphate, 6 parts of ethylene glycol ethyl ether, 2 parts of ethylene-vinyl acetate copolymer, dimethylformamide 5 parts, 3 parts of silica sol, 5 parts of adipic acid, 5 parts of neopentyl glycol, 4 parts of sodium pyrophosphate, 7 parts of oleic acid, 10 parts of polyethylene glycol 400, 4 parts of lecithin, 5 parts of citric acid, 3 parts of magnesium borate.

[0034] The preparation method of the polyether ether ketone wire enamel, comprises the following steps:

[0035] Step 1, mix 4,4'-difluorobenzophenone, hexafluorobisphenol A, hydroquinone, potassium carbonate and sulfolane, react at 120°C for 4 hours, add dropwise a mixture of styrene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com