Straddle type rail ice removal machine

A straddle-type track and deicer technology, which is applied to track cleaning, cleaning methods, construction, etc., can solve the problems of high energy consumption, complex structure, and the inability of ice melting heaters to meet the needs of snow removal, so as to reduce workload. , clean up, clean up the effect of the speed block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

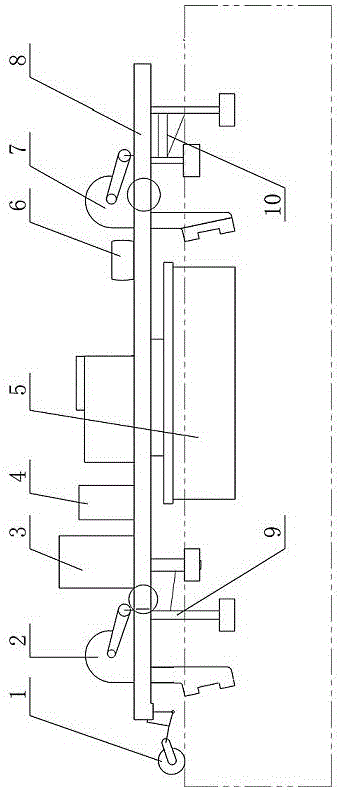

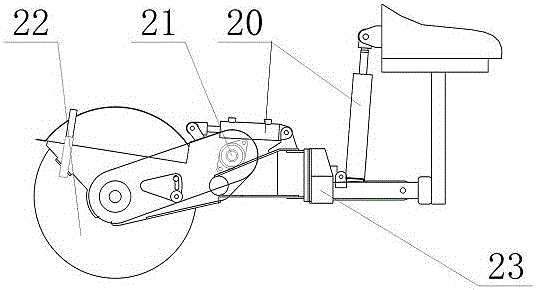

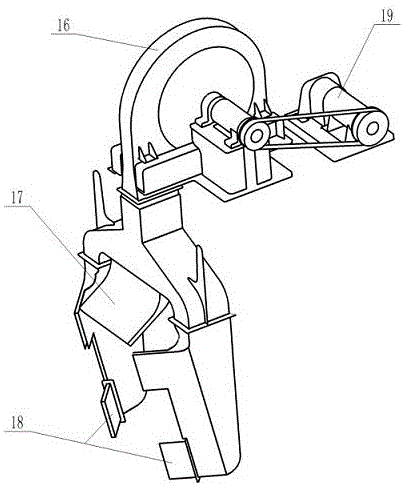

[0015] An embodiment of the present invention is described below in conjunction with accompanying drawing, see figure 1 — Figure 4 , mainly consists of a walking chassis, a roller brush, a blower, a hot air heating device and a cab. The walking chassis 8 is composed of two monorail vehicle bogies connected by longitudinal beams, and one of the bogies 10 is a power bogie; on the walking chassis 8, a snow removal roller brush device 1, a snow removal blowing device 2, and a hot air blower are installed in sequence from front to back. Heating device 5 and deicing water blowing device 7. The described snow removal roller brush device 1 is connected with the walking chassis 8 through a support 23, and the support 23 is provided with an oil cylinder 20 for adjusting the relative position of the roller brush 22 and the track and adjusting the contact pressure between the roller brush and the track, and the roller brush 22 and the hydraulic motor 21 or the motor is connected to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com