Plug-in type bidirectional steel plastic geogrid

A technology of geogrid and two-way steel, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of low strength of structural welds, non-continuous composition, poor structural expansion, etc., and achieves convenient production, installation and operation. , Improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

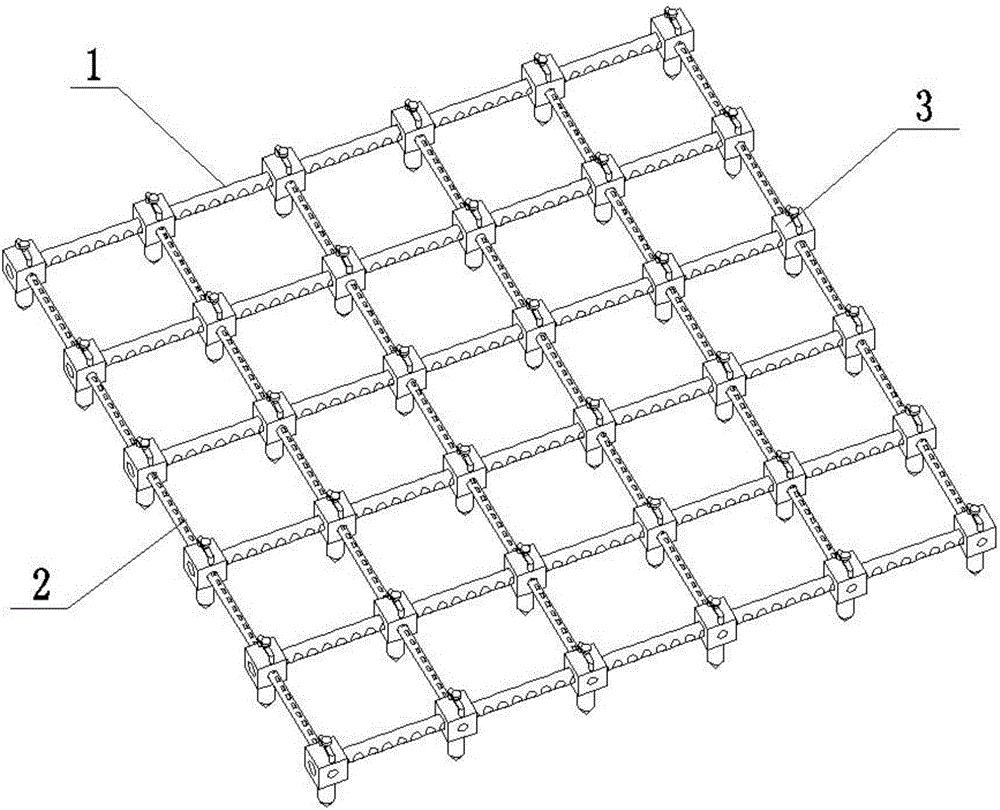

[0024] like figure 1 As shown, the present invention provides a plug-in two-way steel-plastic geogrid, including five first grid bars 1 and five second grid bars 2 perpendicular to each other, the first grid bar 1 and the second grid bar The grid bars 2 are arranged alternately, and the two intersecting first grid bars 1 and the second grid bars 2 are connected by connecting pieces 3 .

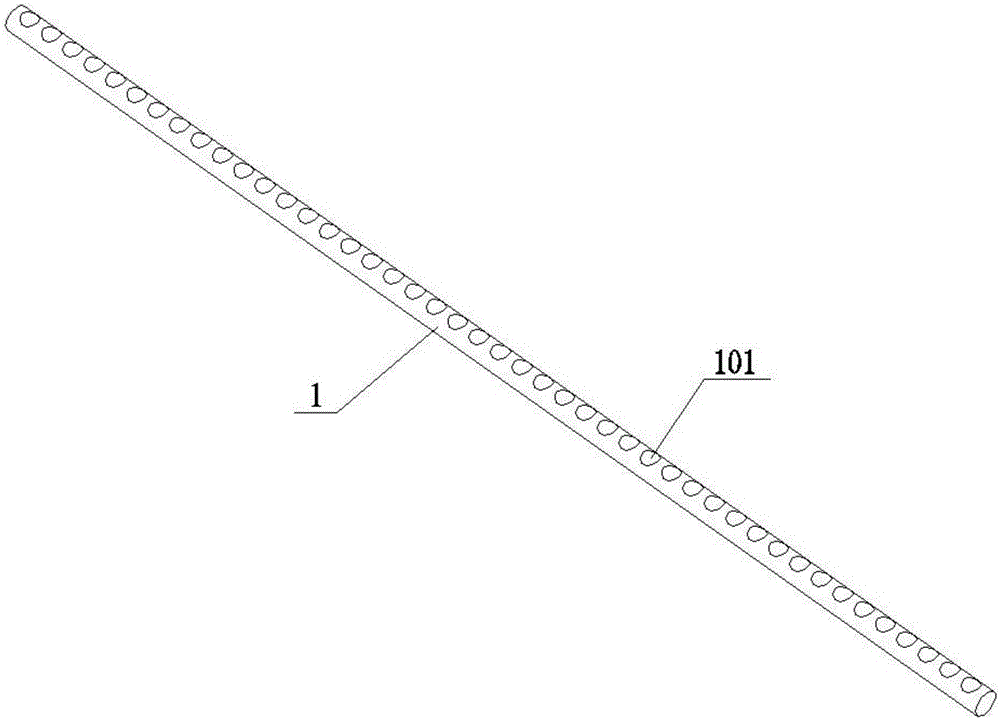

[0025] like figure 2 As shown, the first grid bar 1 is a cylindrical steel-plastic bar with a diameter of 30mm-40mm, and a row of circular jacks 101 are opened equidistantly in the middle of the first grid bar 1, and the jacks 101 are arranged along the first grid. The strips 1 are arranged axially and have a diameter of 10mm-20mm.

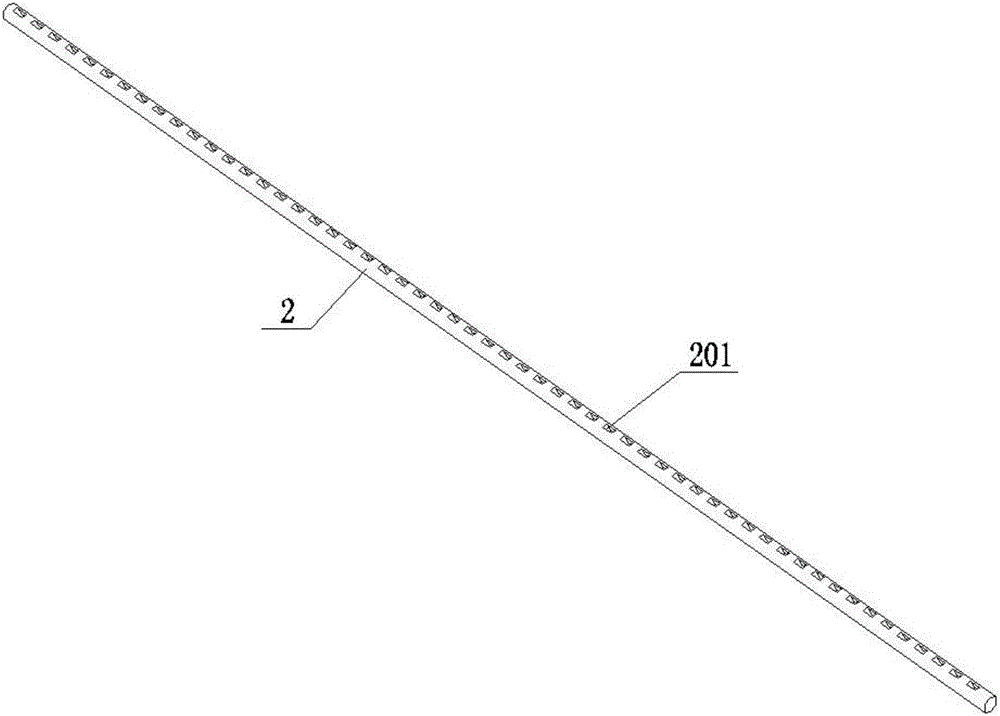

[0026] like image 3 As shown, the second grid bar 2 is a cylindrical steel-plastic bar, and its diameter is adapted to the diameter of the insertion hole 101 . There are two rows of opposite fan-shaped grooves 201 on the peripheral side of the second grid ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com