Combined door leaf

A combined door leaf and door leaf technology, applied in the direction of door leaf, window/door, soundproof door/window, etc., can solve the problems of difficult standardization of door leaf parts, inconvenient door leaf transportation or reprocessing, complicated door leaf assembly process, etc., to achieve Conducive to the protection of resources, diversification of assembly styles, and convenient processing and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

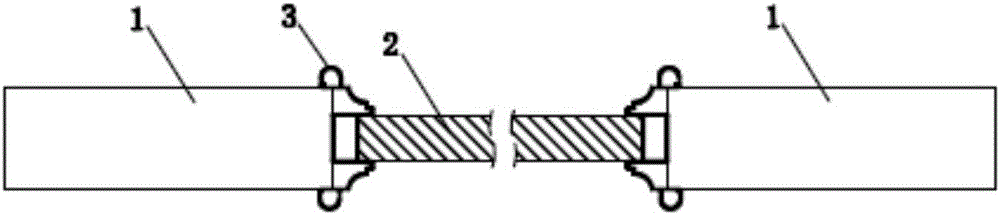

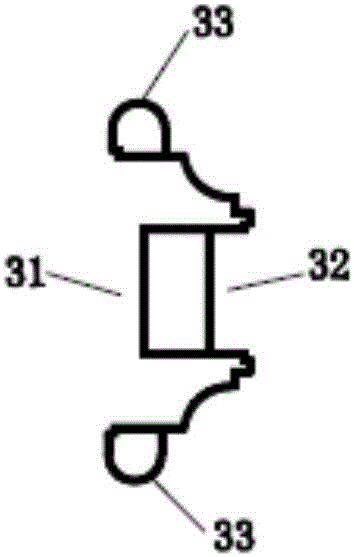

[0040] The specific embodiment of the present invention is as figure 1 As shown, a combined door leaf includes a door leaf frame 1 and a core board 2 . Between the inner edge of the door frame 1 and the edge of the core board 2 is provided a door profile buckle line 3 that can connect the two together. Such as figure 2 As shown, the door profile buckle 3 includes a first connection groove 31 for connecting with the door frame 1 and a second connection groove 32 for connecting with the core board 2 . The door frame 1 and the core board 2 are connected through the door profile buckle wire 3 to form a door leaf. The structure of the door leaf profile buckle line 3 is simple. When assembling the door leaf, first insert the edge of the core plate 2 into the second connection groove 32 on the door leaf profile buckle line 3, and then insert the two on the door frame 1; the door leaf profile buckle line 3 is Profile structure, the first connection groove 31 has a certain degree o...

Embodiment 2

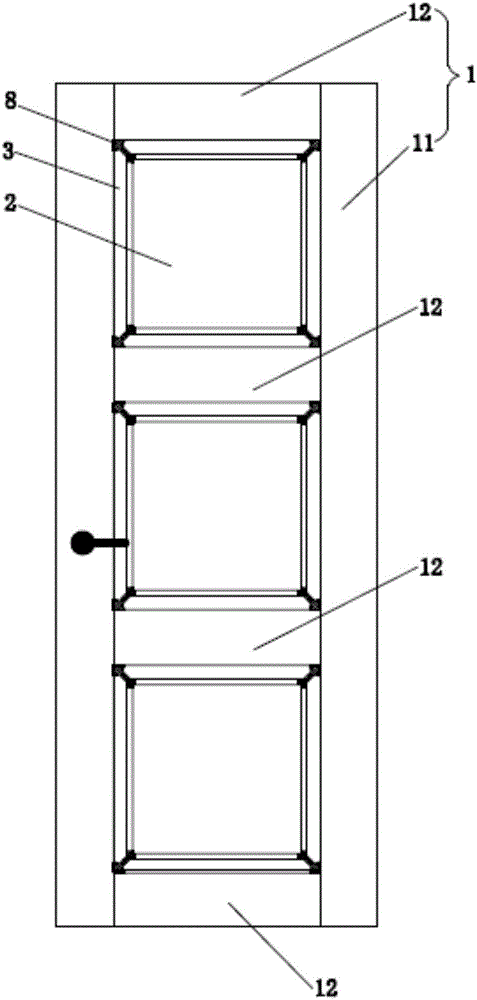

[0043] Such as Figure 3 to Figure 7 As shown, the difference from Embodiment 1 is that the door frame 1 includes at least two vertical beams 11 and at least two horizontal beams 12 . Such as image 3As shown, in this embodiment, the door frame 1 includes two vertical poles 11 and four horizontal poles 12 . The combined door leaf in this embodiment also includes three core panels 2 . The vertical frame 11 and the horizontal frame 12 are connected by bolts 9 . Using the bolt 9 instead of the traditional glue connection method is not only environmentally friendly, but also facilitates the disassembly and assembly of the door frame 1 .

[0044] The inside of one of the vertical frame 11 or the horizontal frame 12 is provided with a counterbore 5 for bolts to enter. Such as Figure 6 As shown, in this embodiment, countersunk holes 5 for the bolts 9 to enter are provided inside the vertical poles 11 , and nuts 10 are embedded in positions corresponding to the bolts 9 on the ho...

Embodiment 3

[0049] Such as Figure 8 As shown, the difference from Embodiment 2 is that in this embodiment, the core board 2 includes two core board assemblies, namely a first core board assembly 21 and a second core board assembly 22 . Wherein, the first core board assembly 21 is a frame structure, and the outer contour of the second core board assembly 22 matches the inner contour of the first core board assembly 21 . Between the first core board assembly 21 and the second core board assembly 22 is provided a core board profile buckle line 4 that can connect the two together. Wherein, the outer edge of the first core board assembly 21 is inserted into the second connection groove 32 on the door leaf profile buckle line 3 . The core plate profile buckle line 4 can be produced as a standard part, with high production efficiency and low cost; the core plate 2 adopts a combined structure, and its appearance can be changed in many ways, and users can customize it according to needs.

[005...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap