Composite impact drilling tool

A technology for percussion drilling and tools, which is applied to drilling equipment, driving devices for drilling in wellbore, and earth-moving drilling, etc., can solve problems such as limiting the application of tools, and achieve the effects of simple structure, improved drilling efficiency, and small length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

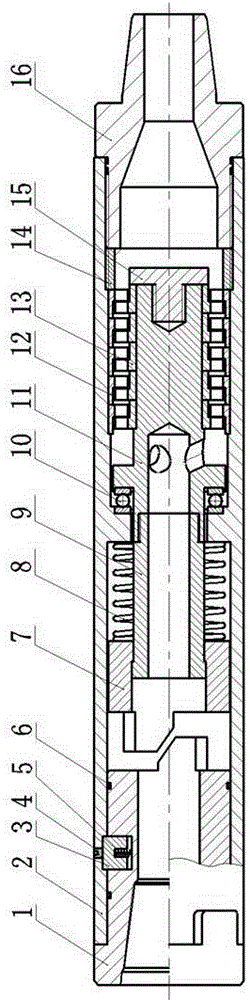

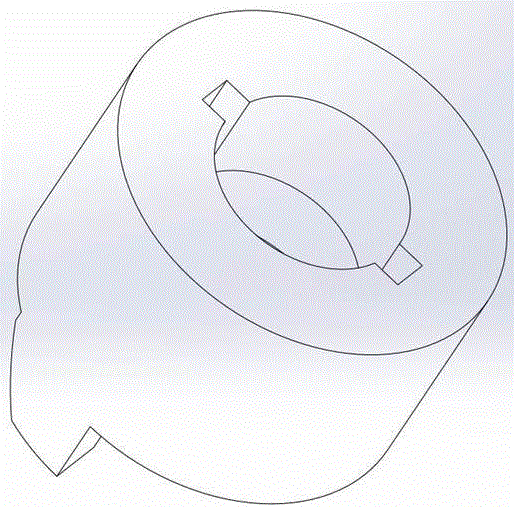

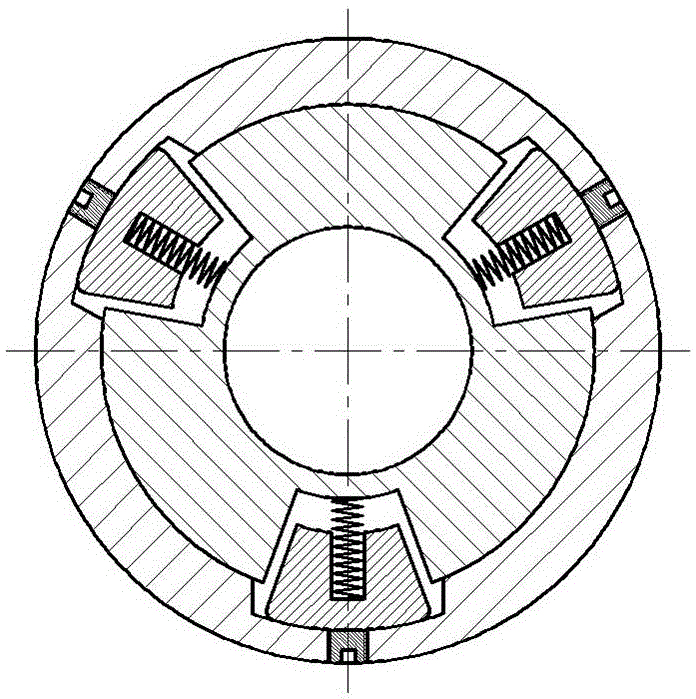

[0022] Such as figure 1 with figure 2 As shown, a compound percussion drilling tool is mainly composed of percussion nipple 1, housing 2, anti-drop block 3, nut 4, radial spring 5, sealing ring 6, percussion hammer 7, axial spring 8, percussion shaft 9. Thrust bearing 10, fixed shaft 11, turbine stator 12, turbine rotor 13, stator pressure cap 14, rotor pressure cap 15 and conversion joint 16, characterized in that the top of the impact sub-joint 1 is provided with a bearing block , the impact block is provided with an inclined surface for bearing the impact of the impact hammer 7; the bottom end of the impact hammer 7 is provided with an impact block, and the impact block is provided with an inclined surface for impacting the impact block of the short joint 1, and the impact hammer 7 The top is provided with a through hole and a rectangular spline groove is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com