Working face equipment positioning system

A positioning system and working face technology, applied in positioning, radio wave measurement system, mining equipment, etc., can solve the problems of inability to meet the precise positioning requirements of intelligent coal mining in coal mines, high cost of ultra-wideband equipment, and difficulty in long-term continuous power supply , to achieve the effect of improving time utilization, solving safety production problems, and reducing manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below in conjunction with accompanying drawing:

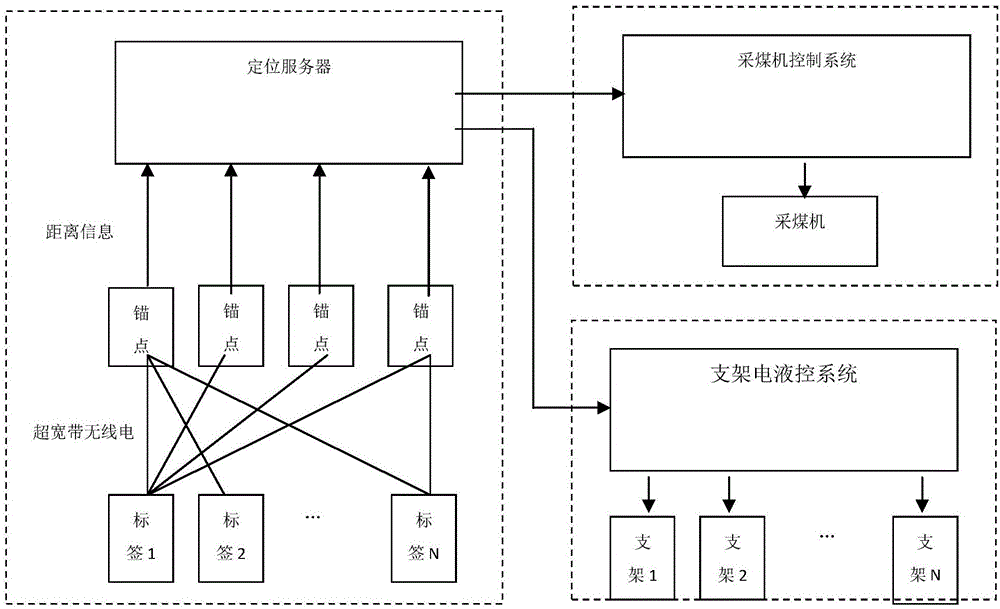

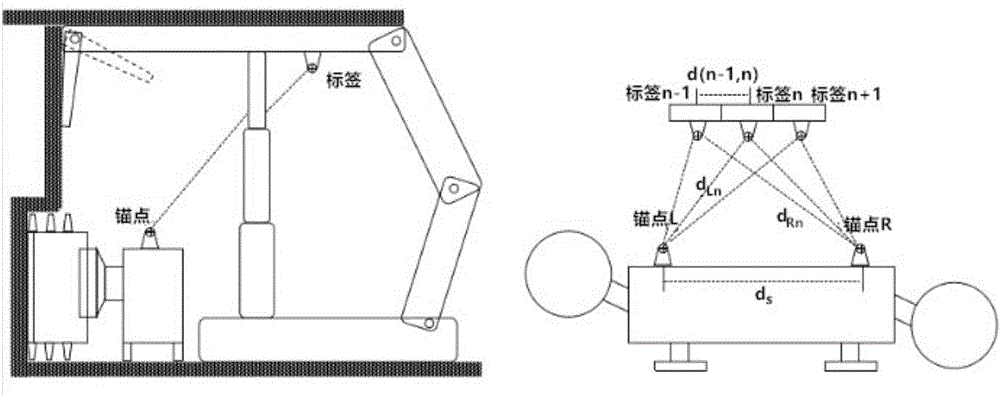

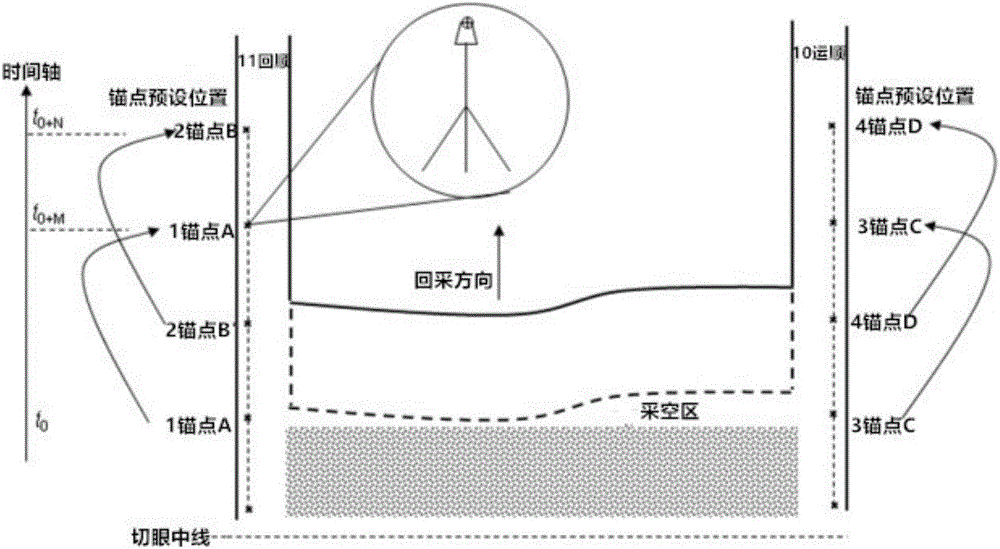

[0017] System composition: positioning anchor point 1, positioning label 5, and positioning server 13. The positioning anchor point mainly completes accurate distance measurement and information access. The positioning tag is used as the object to be positioned, mainly including ultra-wideband ranging and MEMS inertial unit modules, which are used to collect the distance between the anchor point and the tag, as well as the motion state of the tag installation object. The positioning server realizes precise positioning based on data fusion, and is used for data processing and release, such as update calibration of anchor point positions, positioning tag positions, alarm settings, data release, etc.

[0018] Anchor point and label structure: the structure of anchor point and label is similar, as attached figure 2 shown. It mainly includes embedded microprocessor, mainly compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com