Suction dredge pipeline reducing construction method

A cutter suction dredger, construction method technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the difficult control of high-concentration construction, increase pipeline resistance, unfavorable Issues such as energy saving and emission reduction can achieve the effect of increasing the particle size of sand carrying and construction concentration, reducing the load of pumps, and shortening the total construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

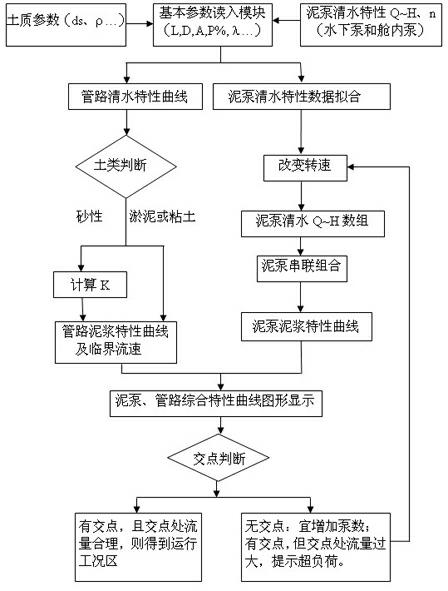

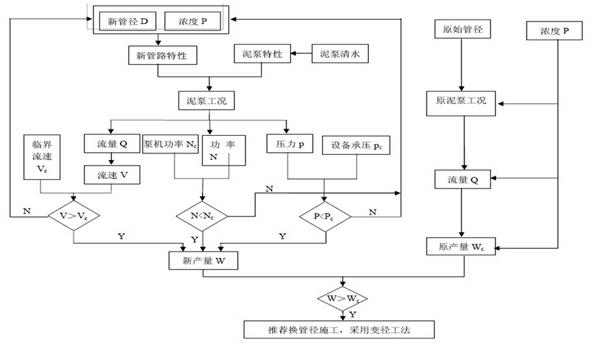

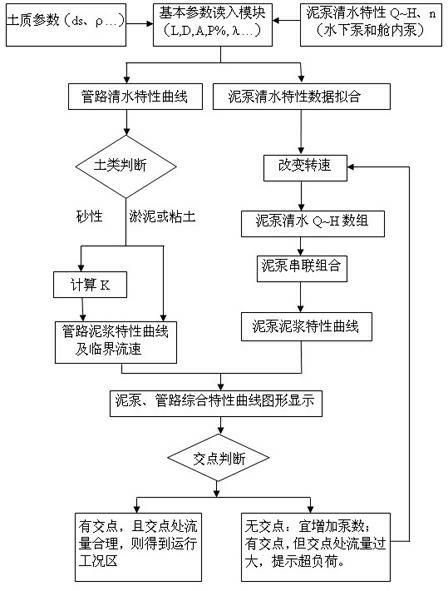

[0040] Refer to attached figure 1 and figure 2 .

[0041] A cutter suction dredger pipeline variable diameter construction method. The dredger uses pumps and pipelines to carry out cutter suction dredging construction. Critical flow velocity, pipeline friction coefficient, and change the diameter of the mud discharge pipe for transportation construction. The pipeline diameter reduction method is adopted to adapt to the characteristics of the dredger pump to achieve the matching construction conditions of the dredger.

[0042] Cutter suction dredger conveying system matching analysis system, using the concept of operations research to establish a cutter suction dredger conveying matching analysis system, including the analysis of the mud pump operating conditions, the analysis of the driving characteristics of the mud pump, the analysis of the critical flow velocity of different soil properties, and the friction coefficient of the pipeline anti-analysis content. Change the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com