Composite two-stage multi-channel gas-liquid jet pump

A jet pump, multi-channel technology, applied in the direction of jet pumps, pumps, non-volume pumps, etc., can solve the problems of too long axial dimension, poor medium transportation and mixing effect, etc., and achieve small axial dimension and simple structure , Improve the effect of conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

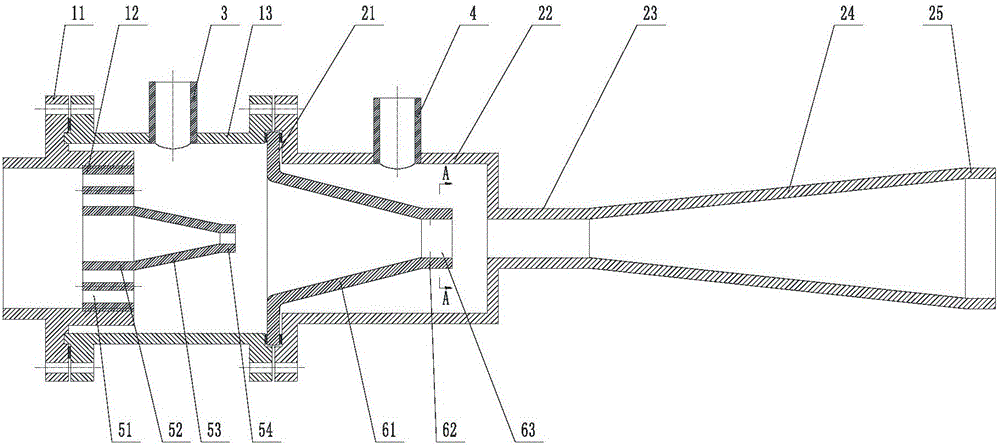

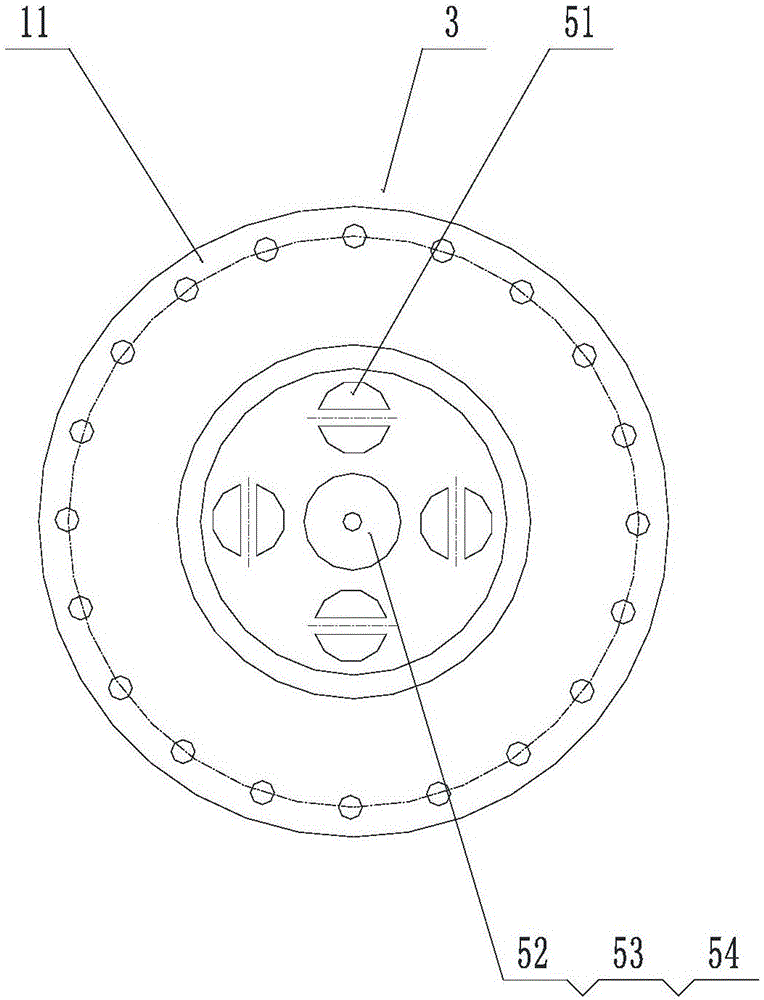

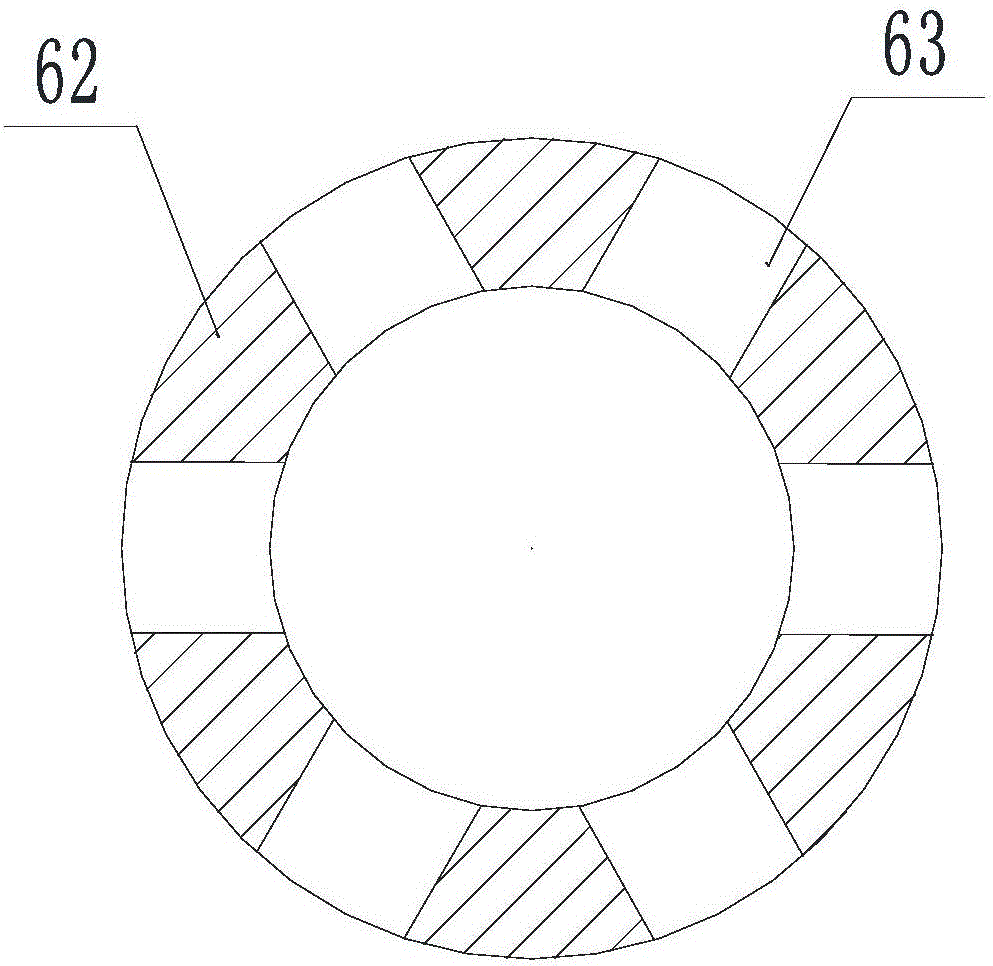

[0022] refer to Figure 1 to Figure 3 , a composite two-stage multi-channel air-liquid jet pump, comprising a primary jet pump body and a secondary jet pump body, the primary jet pump body includes an inlet section 11, a primary nozzle 12 and a primary suction chamber 13, the The inlet section 11 is connected to the first-stage suction chamber 13, the big end of the first-stage nozzle 12 is connected to the inlet section 11 and the small end is located in the first-stage suction chamber 13; The first-stage jet pump body includes a secondary nozzle 21, a secondary suction chamber 22, a throat 23, a diffuser pipe 24, and an outlet section 25. The primary suction chamber 13 and the secondary suction chamber 22 are connected to each other, and the primary suction chamber 22 is connected to each other. The inner side wall of the suction chamber 13 and the secondary suction chamber 22 has a clamping groove for clamping the big end of the secondary nozzle 21 at the junction; the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com