A chassis for a load-bearing device of a reducer

A technology of load-bearing device and reducer, applied in transmission parts, mechanical equipment, belts/chains/gears, etc., can solve the problems of lowering yield and efficiency, insufficient processing accuracy, and increasing processing costs, so as to improve the yield and efficiency, improve the service life, reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

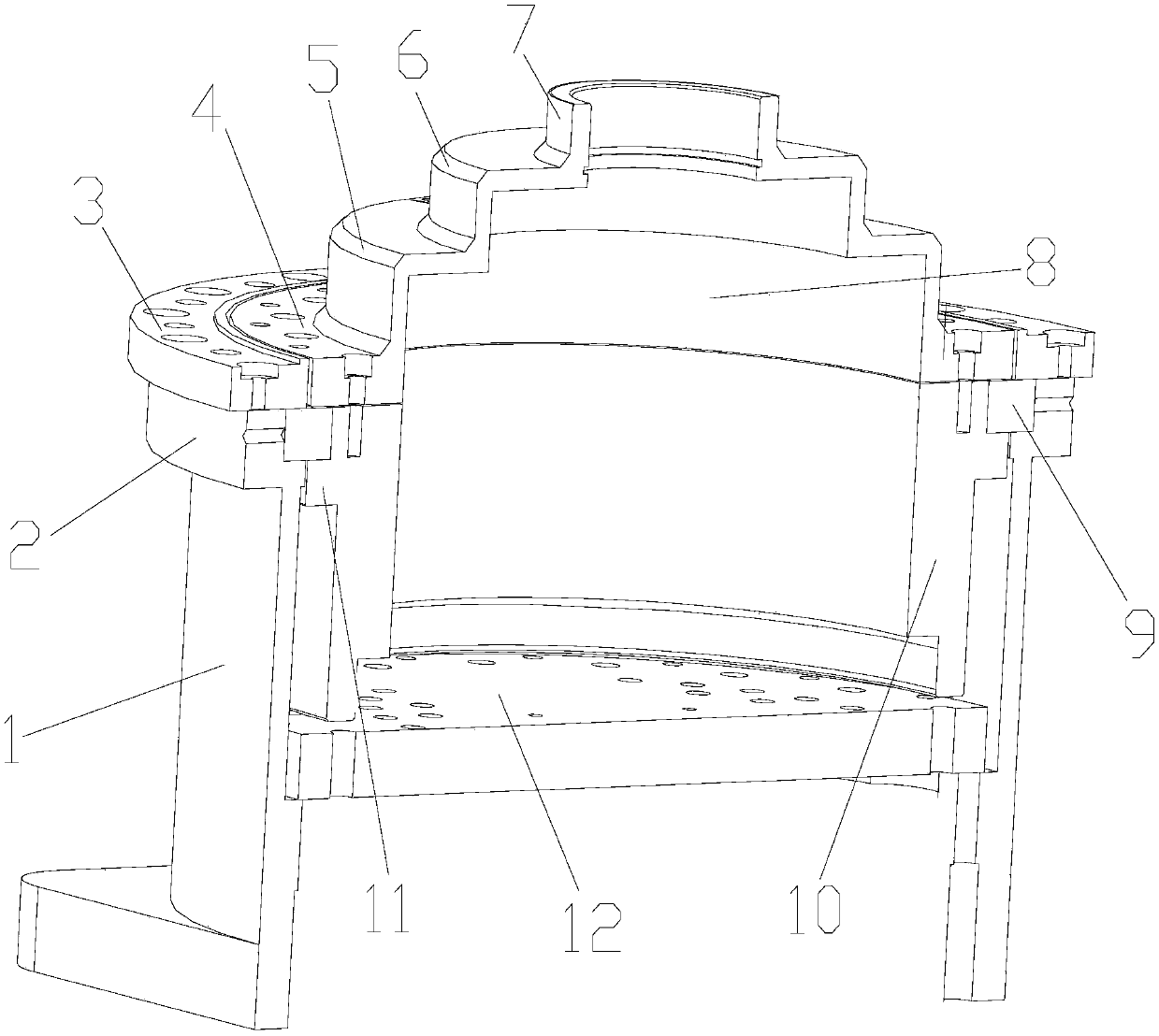

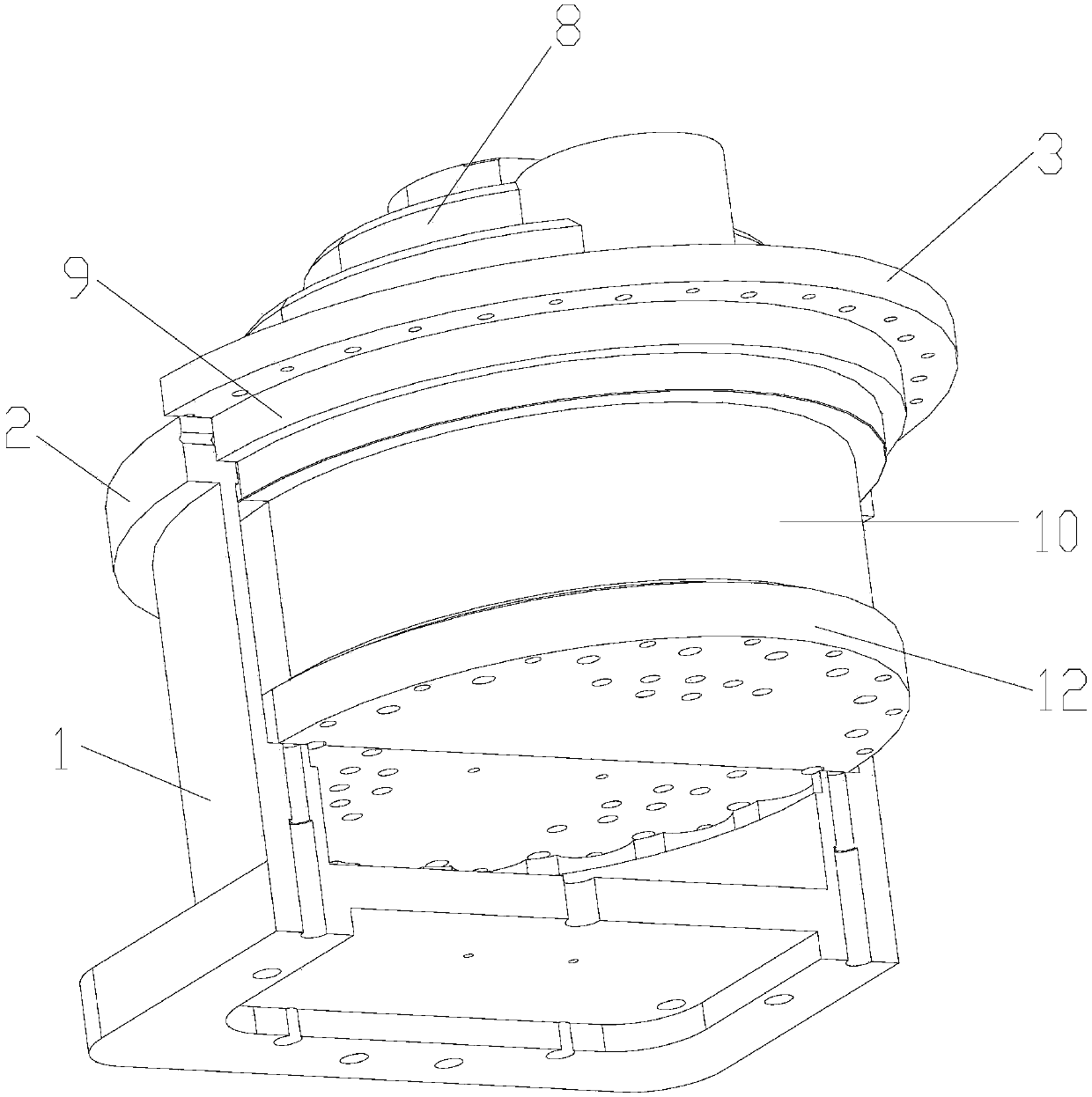

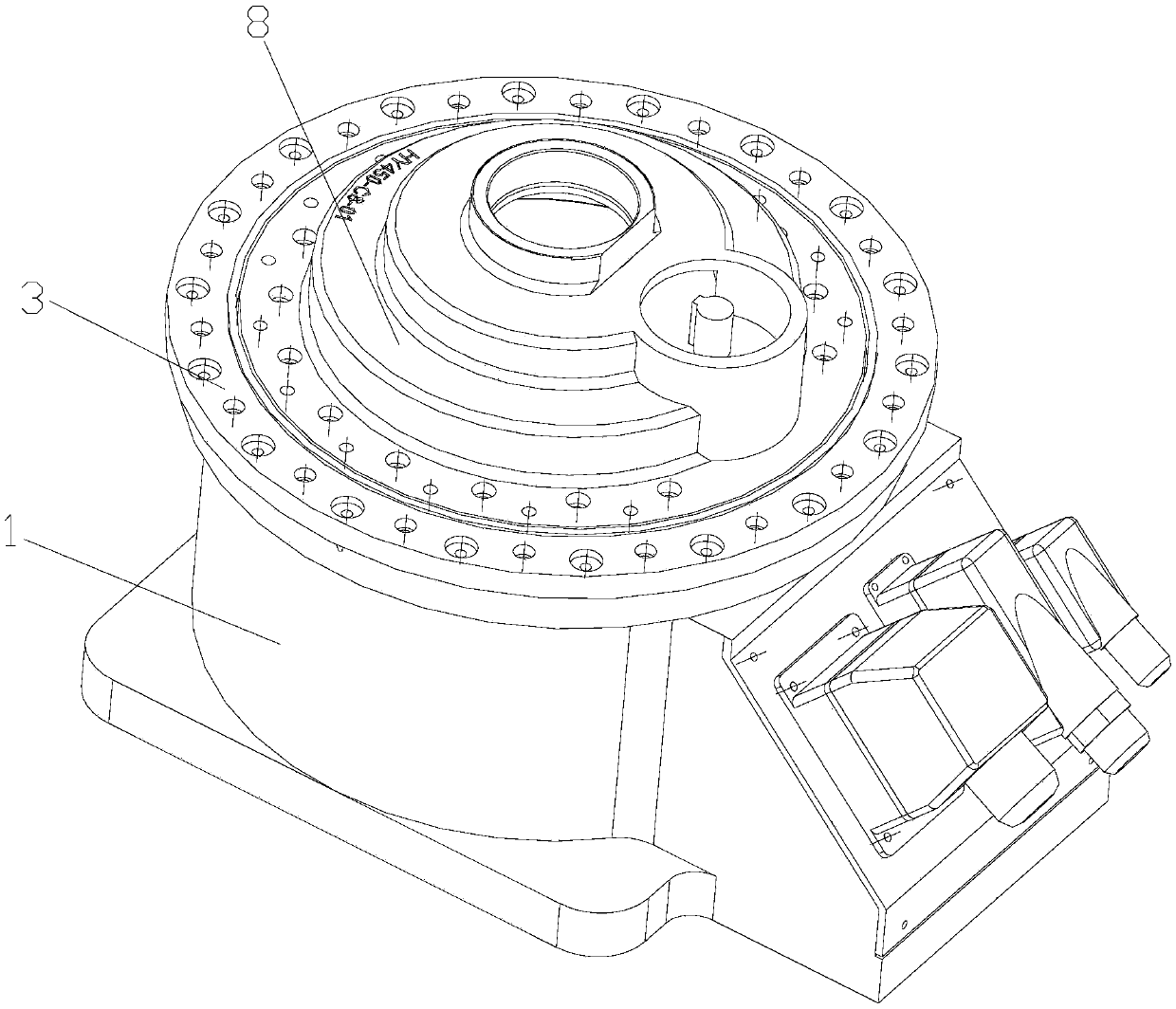

[0030] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0031] combine Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a chassis used for the load-bearing device of the reducer, the chassis includes an inner ring, an outer ring and a latch, the inner ring and the outer ring are generally disc-shaped, the outer ring is provided with a central hole, and the inner ring Placed in the center hole of the outer ring, the inner ring and the outer ring jointly form a plurality of pin holes evenly distributed along the circumferential direction, and the pins pass through the pin holes; the outer ring of the chassis is fixed inside the load-bearing device , the inner ring of the chassis is connected to the reducer. The outer diameter of the inner ring is equal to the diameter of the central hole of the outer ring.

[0032] Viewed from the end face of the inner ring, there are multiple semici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com