Natural gas buried pipe anti-frost heaving system combining solar energy and geothermal energy

A technology of natural gas and geothermal energy, applied in solar heating systems, solar thermal energy, components of solar collectors, etc., can solve the problems of pipeline frost heave, uncertainty of minimum quantity, slow heat exchange of heat pipes, etc. Energy consumption, significant environmental benefits, and the effect of avoiding pipeline frost heave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

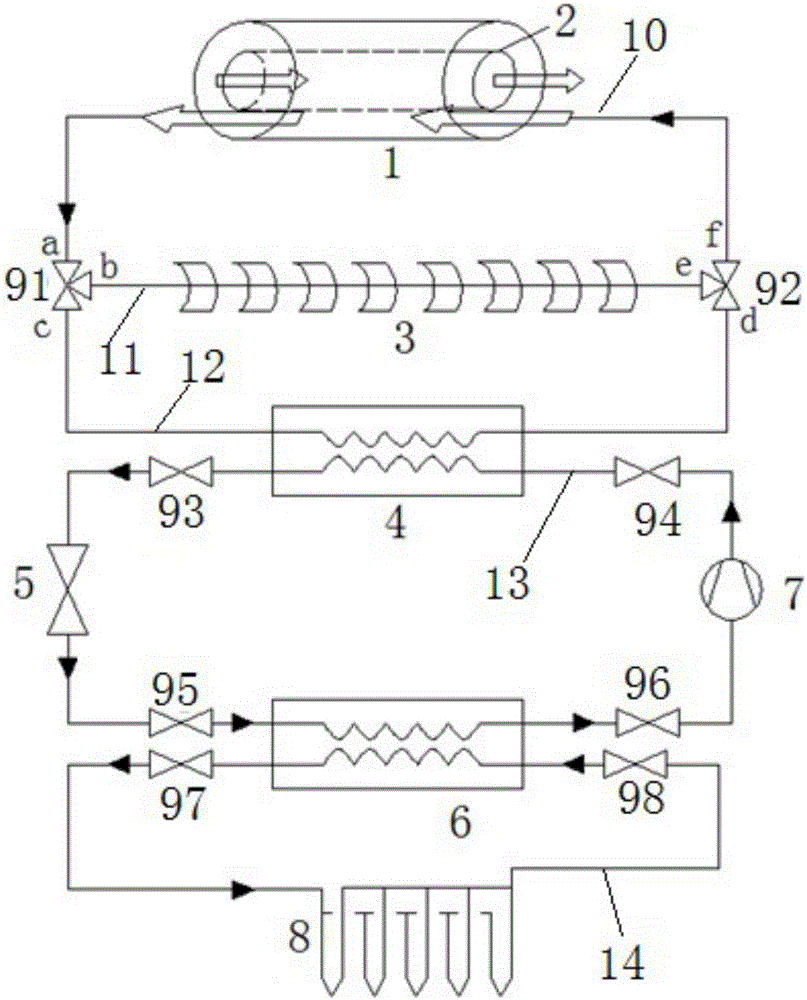

[0033] An anti-frost heave system for buried natural gas pipelines that combines solar energy and geothermal energy, such as figure 1 As shown, it includes a pipeline heat exchange device 1, a solar heat collection device 2 and a ground source heat pump. The pipeline heat exchange device 1 is composed of a natural gas buried pipe 2 and a heat exchange medium channel for heat exchange with the natural gas buried pipe 2. Two ends of the heat medium channel are connected with a heat exchange medium main pipe 10, and a first branch pipe 11 and a second branch pipe 12 are connected in parallel on the heat exchange medium main pipe 10 through a first three-way valve 91 and a second three-way valve 92. One pipe 11 is provided with a solar heat collecting device 3, and the second heat exchange branch pipe 12 is provided with a ground source heat pump.

[0034] Specifically: the pipe heat exchange device 1 is a double-pipe heat exchanger adopting countercurrent heat exchange, the inner pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com