Testing device for position accuracy and surface profile of flange

A detection device and surface profile technology, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems of high utilization rate of three-coordinate detection machines, expensive equipment of three-coordinate detection machines, and the actual length of waiting for detection. Achieve the effect of reducing the secondary detection time, improving the production cycle and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

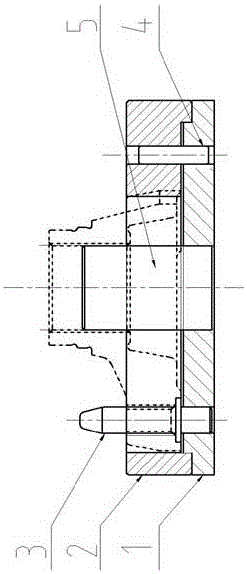

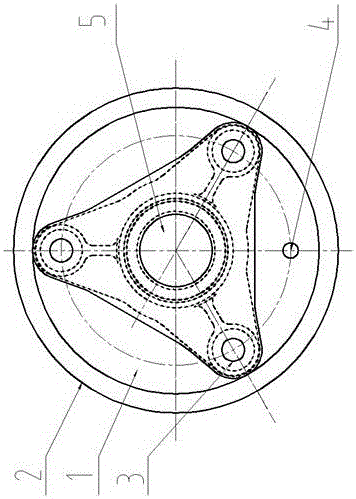

[0015] A combination type and insertion type flange position degree and surface contour degree detection device, which includes a detection body 1, a shape plate 2, a latch 3, a positioning pin 4 and a positioning shaft 5. The shape plate 2 and the inspection body 1 cooperate through the inner and outer spigot structures. The shape plate 2 and the inspection body 1 form an inner cavity space for placing the flange. The positioning pin 4 restricts the degree of freedom of the shape plate. The bolt 3 installation holes provided on the inspection body 1 are fixed on the inspection body 1 to form a measuring gauge for detecting the flange position. The positioning shaft 5 is fixed on the inspection body 1 through the positioning shaft 5 mounting holes provided on the inspection body 1. The shaft 5 forms the flange positioning datum, and the shape plate 2 forms a contour gauge for detecting the flange surface.

[0016] The bolt 3 cooperates with the mounting hole of the bolt 3 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com